A gas slag collection and separation device for coal mine punching

A separation device and punching technology, which is applied in construction and other directions, can solve the problems of spray hole punching site environment, gas outburst, harshness, etc., and achieve the effects of improving the environment, preventing gas outburst, and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

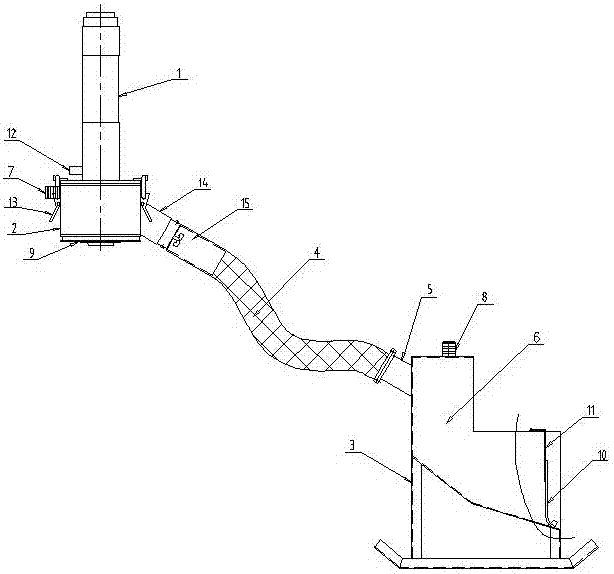

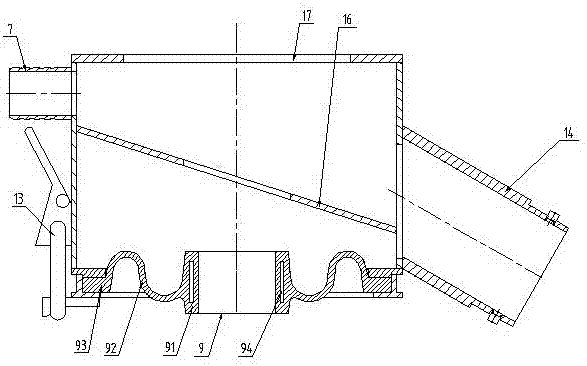

[0011] Such as figure 1 As shown, a gas slag collection and separation device for coal mine punching includes a collection box 2 and a separation box 3. One side of the collection box 2 is provided with a fixing device 1 for fixing in the gas drainage hole. The fixing device 1 The interior of the collection box 2 is provided with a fluid channel that communicates with the interior of the collection box 2 through the fluid inlet I17 provided on the collection box 2. The other side of the collection box 2 opposite to the fixing device 1 is provided with an opening for the punching drill rod to pass through. The opening is set opposite to the fluid passage, so that the punching drill rod can pass through the fluid passage and enter the gas extraction hole. The collection box 2 is provided with a fluid outlet 14, and the fluid outlet 14 passes through the pipeline 4 and the separation box 3 The upper part of the fluid inlet II5 is connected, and the fluid inlet II5 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com