A protection structure for solder joints of condensing heat exchanger

A technology for condensing heat exchangers and protective structures, which is applied in the direction of damage protection, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of difficulty in meeting the anti-corrosion requirements of condensing heat exchangers, large internal and external pressure differences of solder joints, and strong solder joints. Corrosion and other issues, to achieve the effect of ensuring reliability, long service life, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

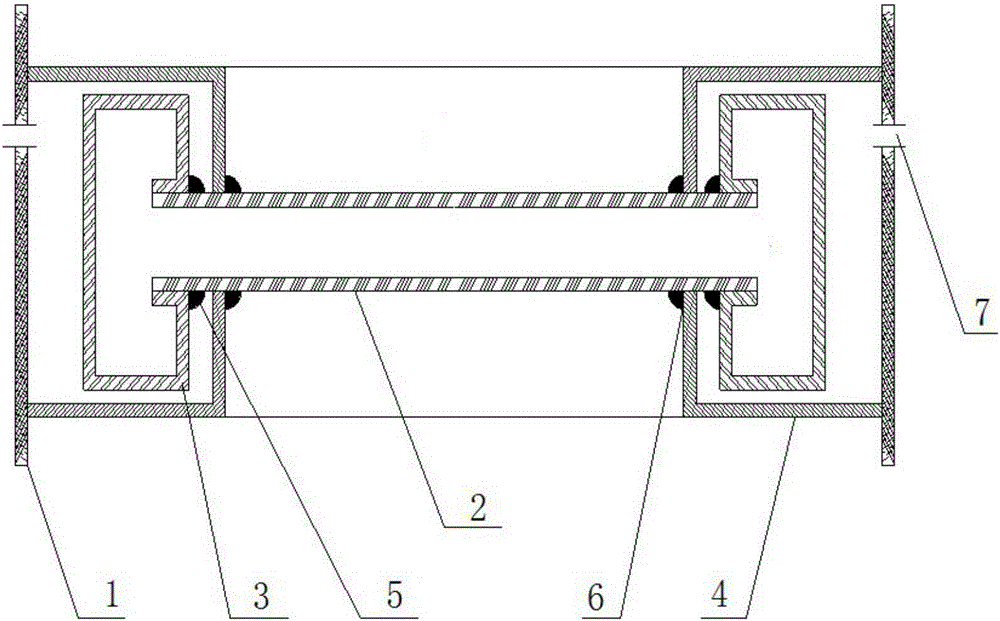

[0022] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific embodiments of the present invention are described in detail below with reference to the accompanying drawings.

[0023] like figure 1 As shown in the figure, a welding point protection structure of a condensing heat exchanger is characterized in that a fume isolation cavity is provided around the welding point 5 of the stainless steel heat exchange tube 2, the fume isolation cavity completely surrounds the welding point, and the smoke The housing of the gas-isolated chamber is not in contact with the solder joints 5 .

[0024] In this embodiment, it is preferable that the flue gas isolation chamber is surrounded by an isolation baffle 4 and the condensing heat exchanger shell 1 , and the isolation baffle 4 and the stainless steel heat exchange tube 2 are fixed by welding. In this way, during actual operation, the high temperature and high humidity fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com