Gate water-stop dam face unevenness underwater measuring device and method

A technology of underwater measurement and water stop dam, applied in the direction of measuring devices, instruments, etc., can solve the problems of affecting the water sealing effect of the floating gate, unevenness of the dam surface, and difficulty in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

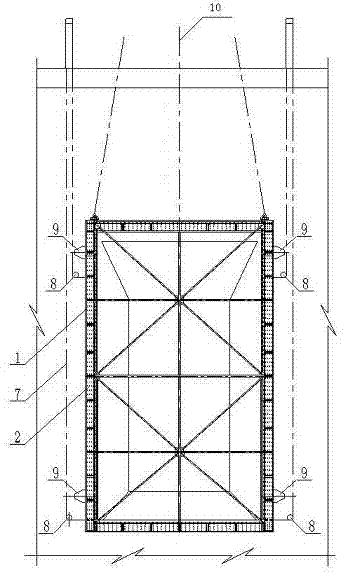

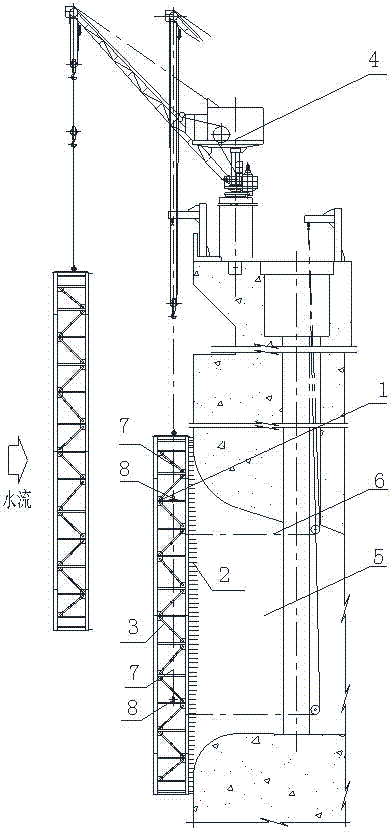

[0028] The underwater measuring device for the unevenness of the gate water stop dam surface of the present invention is specifically a measurement frame 1, the downstream surface of the measurement frame 1 and the corresponding position of the gate water stop dam surface are provided with uniformly arranged measuring needles 2, and the measurement The needle 2 is movably connected with the measuring frame 1, and can expand and contract along the direction vertical to the dam surface.

[0029] The measuring needle 2 can form a curved surface through expansion and contraction, and the formed curved surface is the surface of the water stop dam to be blocked. The structure of measurement box 1 is as follows figure 1 and figure 2 shown.

Embodiment 2

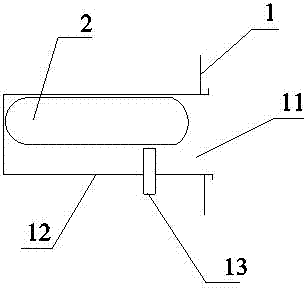

[0031] In this embodiment, on the basis of Embodiment 1, as a preference, a probe hole 11 is provided on the downstream surface of the measurement frame 1 corresponding to the surface of the gate dam, and a probe hole 11 is provided in the probe hole 11. cylinder 12, the needle cylinder 12 is provided with a needle 2, the needle 2 can be extended and retracted along the direction vertical to the dam surface, and a bolt 13 is also arranged in the needle cylinder, and the bolt 13 is perpendicular to the needle 1 , to fix or loosen stylus 1. image 3 It is an enlarged cross-sectional view of the stylus cylinder 12 when the stylus 2 is received in the stylus cylinder 12, and the bolt 13 is in a loosened state in the figure; Figure 4 It is an enlarged cross-sectional view of the stylus cylinder 12 when the stylus 2 extends out of the stylus cylinder 12. In the figure, the bolt 13 is in a tightened state, and the stylus 2 is fixed at this time.

[0032] Before the measuring frame ...

Embodiment 3

[0034] In this embodiment, on the basis of embodiments 1 and 2, the downstream surface of the measuring frame 1 and the corresponding part of the gate dam surface are provided with evenly arranged measuring needles 2, and the arrangement spacing of the measuring needles 2 on the measuring frame is 100 ~ 300mm. The size of the spacing depends on the measurement accuracy of the measured curved surface, and the number of measuring needles 2 is hundreds or thousands, forming a needle comb. The stylus 2 is rod-shaped, which can be a nylon rod or a wooden rod, or other rod-shaped materials with certain strength and lightness for underwater operation. The top of the stylus 2 is smooth.

[0035] In this embodiment, the water stop surface of the gate to be measured by the measurement frame 1 is the uneven concrete dam surface, and the measurement range is the height of local pits, bosses and penetrating grooves within the water stop zone of the concrete dam surface. value, the stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com