Exhaust process simulator of safety valve on rocket

A technology of exhaust process and simulating device, which is applied in the direction of measuring device, engine test, machine/structural component test, etc. It can solve the problem of limited number of normal working times of movable parts and seals, and improve the level of human-computer interaction. , improve adaptability, improve the effect of system utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

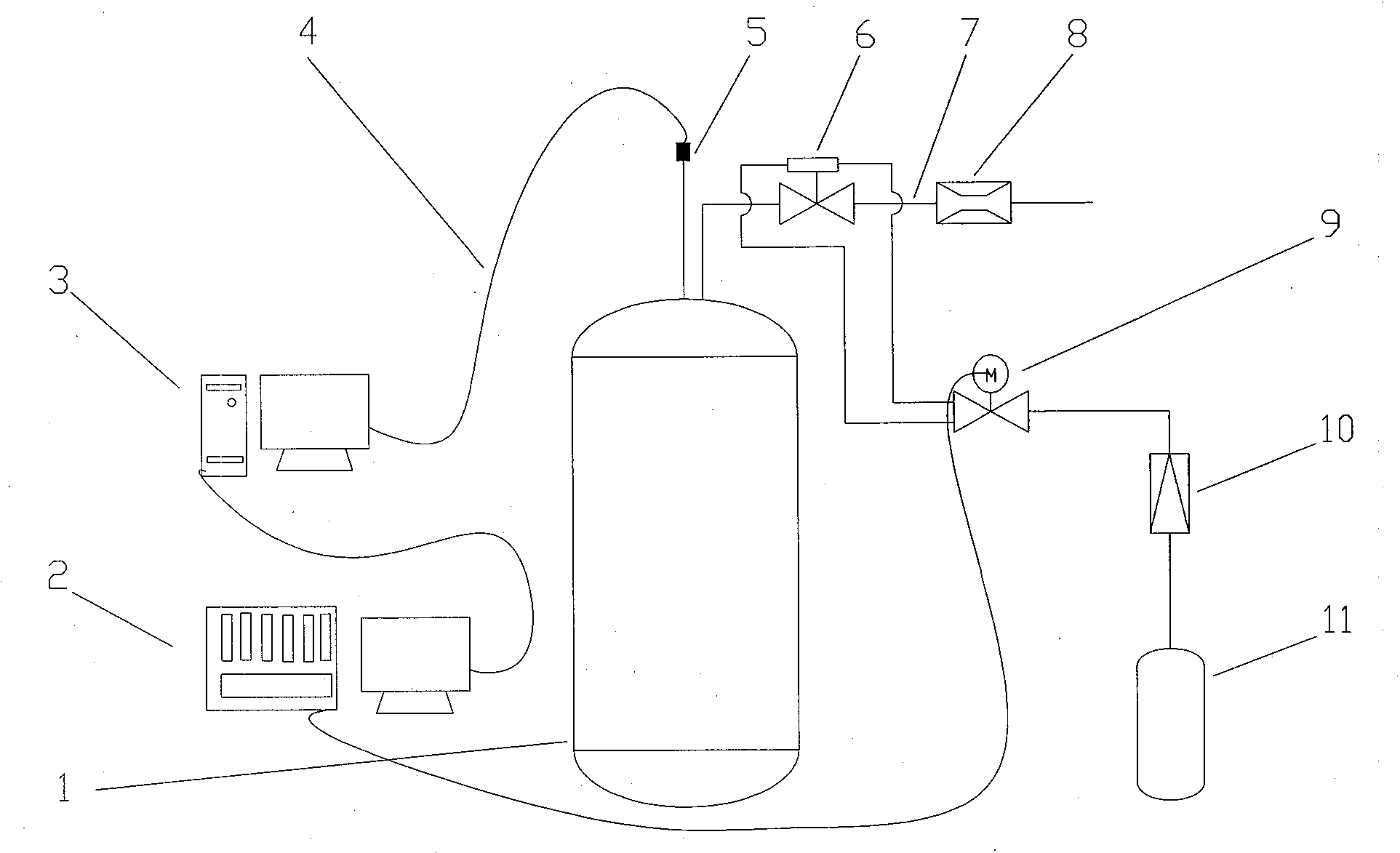

[0013] Such as figure 1 As shown, the present invention mainly consists of a program controller 2, a data acquisition processor 3, a cable 4, a pressure sensor 5, a low-temperature pneumatic valve 6, a connecting pipeline 7, an orifice plate 8, a two-position five-way solenoid valve 9, and a pressure reducing valve. 10. The nitrogen cylinder is composed of 11. Among them, the program controller 2, the data acquisition processor 3, the cable 4, and the pressure sensor 5 form the pressure measurement and command generation system of the propellant tank 1; the exhaust gas flow is limited by the orifice plate 8; Road 7, solenoid valve 9, decompression valve 10 and nitrogen cylinder 11 form instruction execution mechanism.

[0014] During the work of the present invention, at first in the data acquisition processor 3, setting safety valve return seat pressure is P min , the opening pressure is P max ; The pressure sensor 5 perceives the pressure value of the propellant tank 1 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com