A wire rope stress on-line monitoring sensor

A monitoring sensor and wire rope technology, applied in the field of wire rope stress on-line monitoring sensors, can solve the problems of inconvenient on-line monitoring, high technical level requirements, complicated equipment and other problems, and achieve flexible use, high measurement accuracy and sensitivity, and easy availability of materials and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

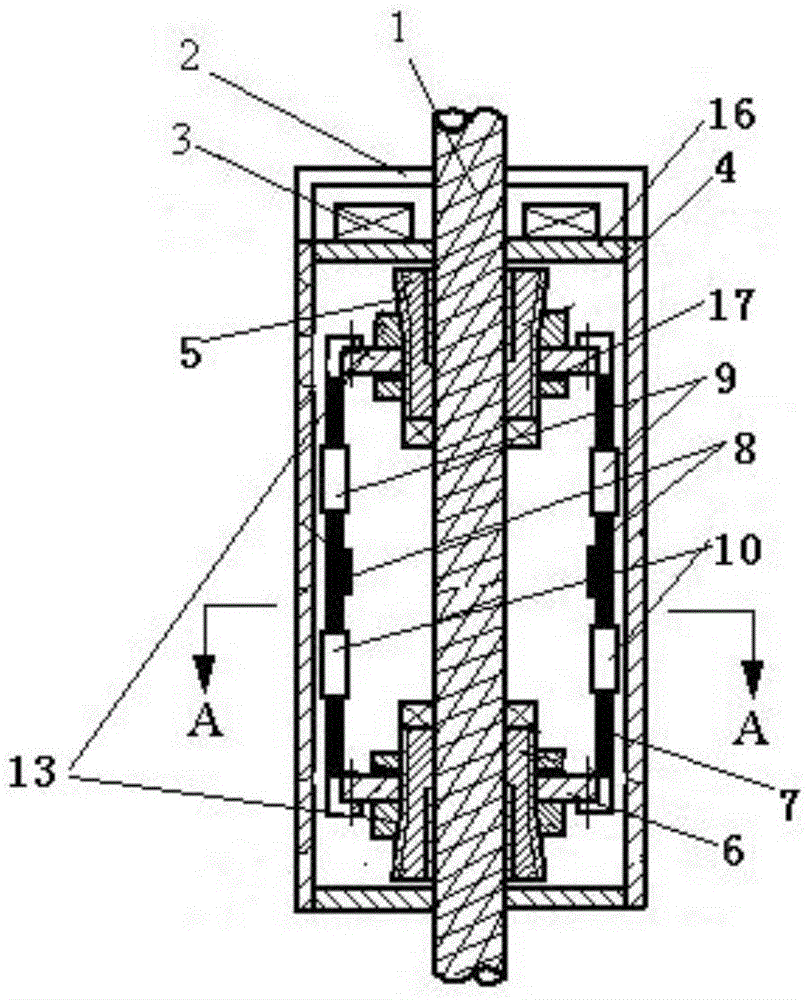

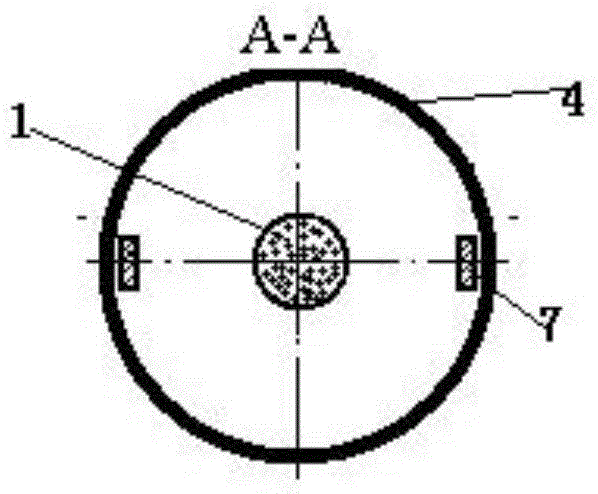

[0030] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

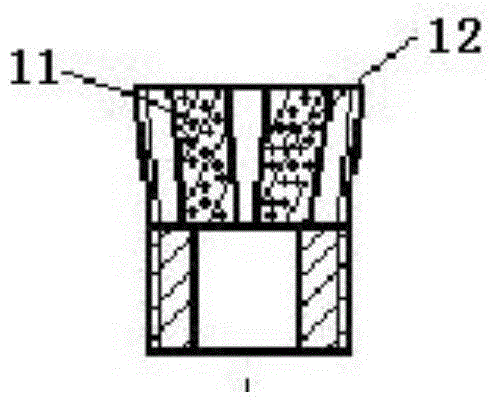

[0031] Such as Figure 1 to Figure 4 As shown, a kind of wire rope stress on-line monitoring sensor of the present invention comprises a shielding case 4 and a sensing device installed in the shielding case 4, and the sensing device includes the same two ferrules 6 installed up and down, and two ferrules 5 The outer surface of the outer surface is equipped with a pull plate 6, and two stress-sensitive bands 7 made of nano-microcrystalline ferromagnetic alloy are arranged between the upper and lower two same pull plates 6, and the shown stress-sensitive bands 7 are all pasted with resistors. The strain gauge 8, and the excitation coil 9 and the measurement coil 10 are also wound on the stress sensitive strip 7. Wherein, the ferrule 5 and the pull plate 6 are provided with corresponding ferrule lock nuts 13 and pull plate lock nuts, and a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com