Stress, strain or temperature abnormal area monitoring sensing element and manufacturing method thereof

A technology for sensing elements and abnormal areas, applied in the direction of measuring devices, instruments, etc., can solve the problems affecting the test accuracy, difficult temperature field measurement, application scope limitations, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

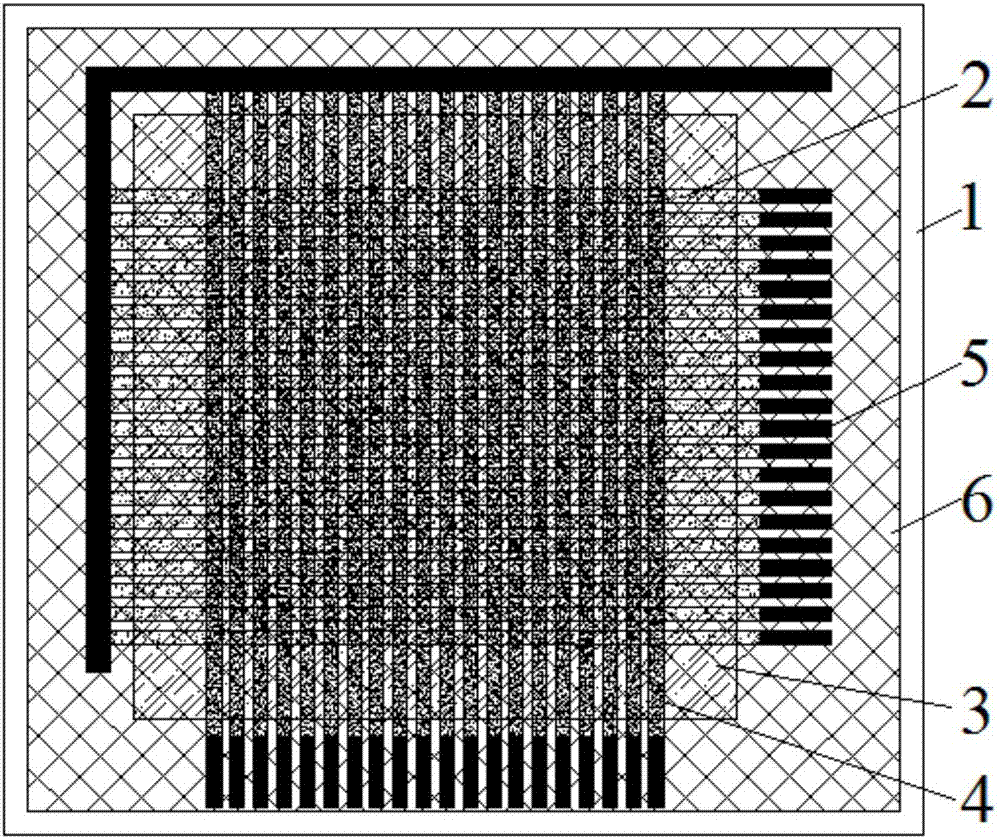

Embodiment 1

[0030] Embodiment 1: Assuming that the content to be monitored is a stress abnormal region in a plane field, it is relatively simple to initially determine the shape of the abnormal region. Such as figure 1 As shown, the basic composite layer structure of the sensor element for stress, strain or temperature anomaly monitoring in the plane field of the present invention includes a thin plate 1 of the first layer (bottom layer), a lateral arrangement of sensitive elements of the second layer 2, and a third layer of An insulating thin layer 3, a longitudinal array of sensitive elements 4 on the fourth layer, an electrode 5 on the fifth layer, and an insulating protective film 6 on the sixth layer (the uppermost layer). Since the monitoring content is the abnormal stress area in the plane field, the thin plate 1 is made of polyimide film with high compressive strength, the thickness is 0.1mm; the insulating material is epoxy resin, which is used for printing the insulating thin la...

Embodiment 2

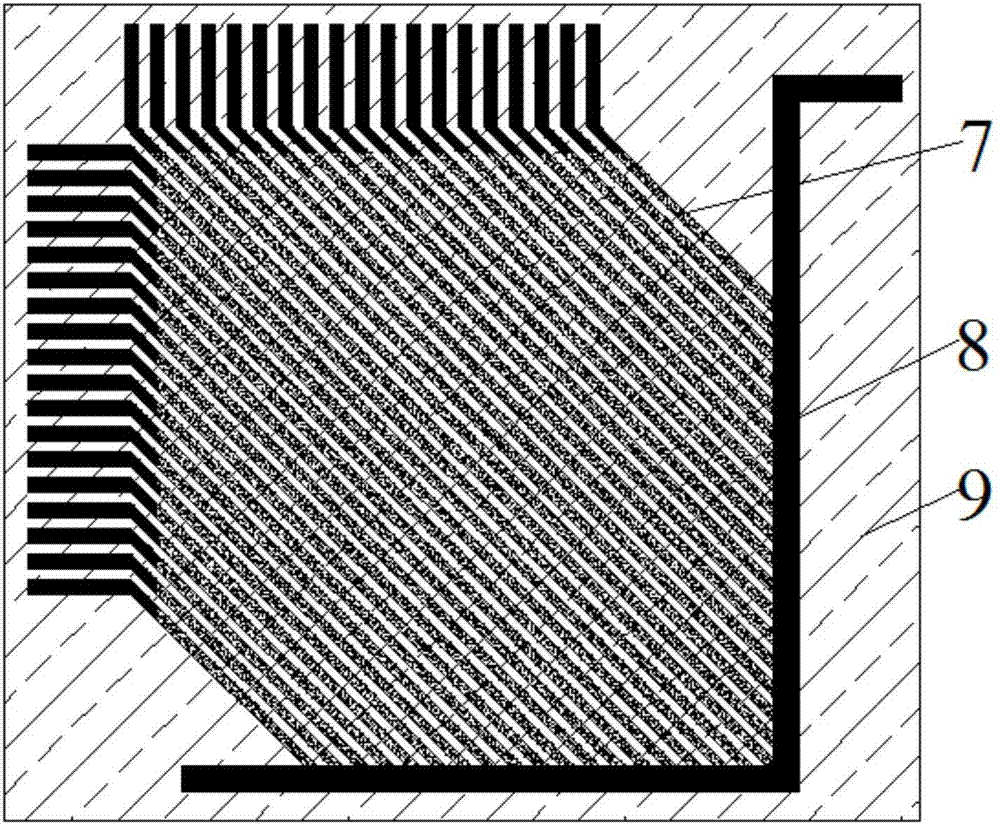

[0032] Embodiment 2: Assuming that the content to be monitored is an abnormal stress region in a plane field, the shape of the abnormal region is preliminarily judged to be complex. Such as figure 1 and figure 2 As shown, the stress, strain or temperature anomaly region monitoring sensor element in the plane field of the present invention includes a basic composite layer structure and an additional composite layer structure, wherein the basic composite layer structure includes a thin plate 1 of the first layer (bottom layer), a second layer Transverse array of sensitive elements 2, thin insulating layer 3 of the third layer, longitudinal array of sensitive elements 4 of the fourth layer, electrode 5 of the fifth layer and insulating protective film 6 of the sixth layer (uppermost layer); additional composite layer structure It includes a first layer (bottom layer) of sensitive element array 7 and electrodes 8 and a second layer (upper layer) of insulating protective film 9 ....

Embodiment 3

[0034] Embodiment 3: Assuming that the content to be monitored is an abnormal strain region in a plane field, it is relatively simple to initially determine the shape of the abnormal region. Such as figure 1 As shown, the basic composite layer structure of the sensor element for stress, strain or temperature anomaly monitoring in the plane field of the present invention includes a thin plate 1 of the first layer (bottom layer), a lateral arrangement of sensitive elements of the second layer 2, and a third layer of An insulating thin layer 3, a longitudinal array of sensitive elements 4 on the fourth layer, an electrode 5 on the fifth layer, and an insulating protective film 6 on the sixth layer (the uppermost layer). Since the monitoring content is the abnormal strain area in the plane field, the thin plate 1 uses a polyurethane film with high deformation resistance and a thickness of 0.1mm; the insulating material is silicon rubber, which is used to print the insulating thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com