A polysilicon stress sensor and its manufacturing method

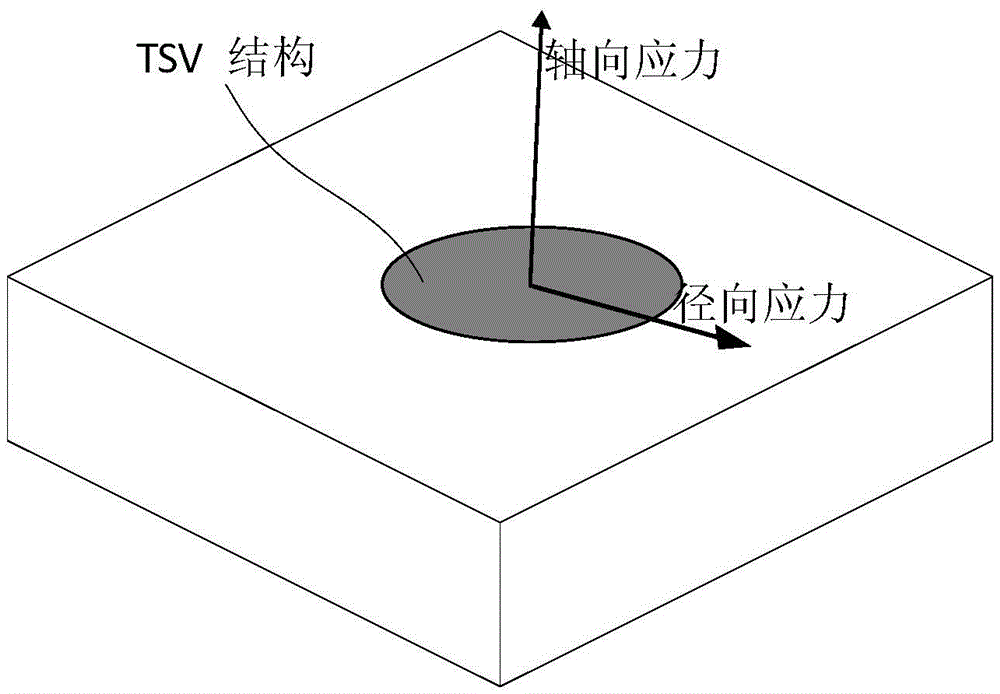

A technology of stress sensor and manufacturing method, which is applied in the fields of integrated circuit manufacturing, packaging and measurement, and can solve problems such as TSV damage and inability to reflect the thermal stress status of TSV structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

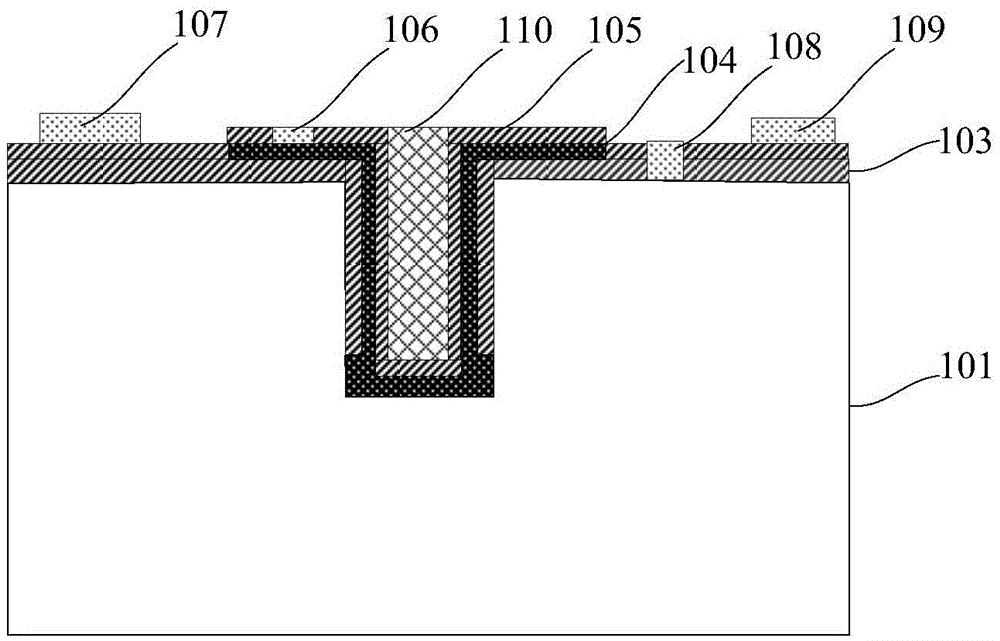

[0057] like figure 2 As shown, this embodiment provides a polysilicon stress sensor, including at least:

[0058] Silicon substrate 101;

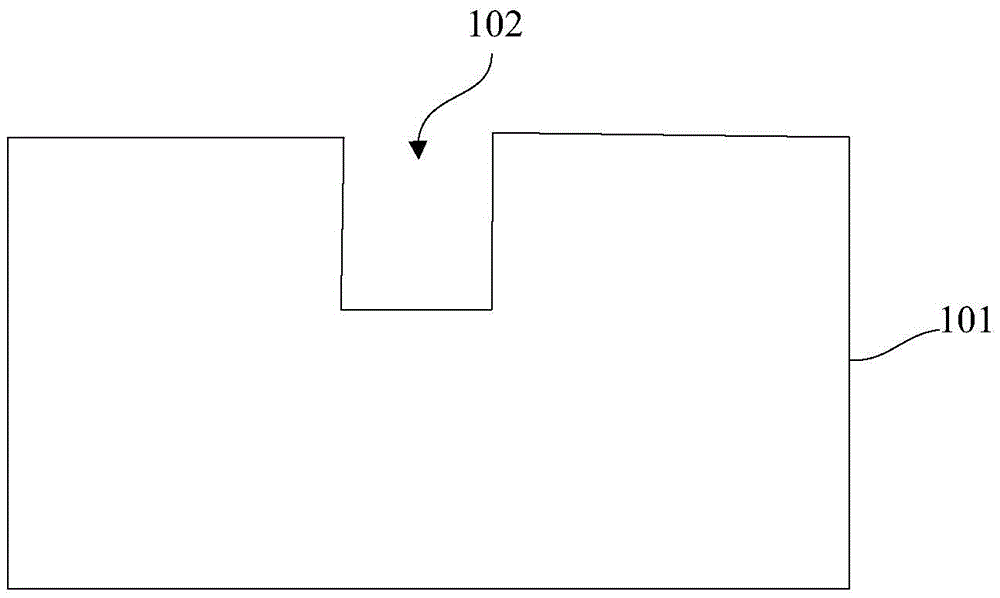

[0059] a silicon hole structure 102 formed in the silicon substrate 101;

[0060] The first barrier layer 103 covers the front surface of the silicon substrate 101 and the upper sidewall of the silicon hole structure 102;

[0061] a polysilicon layer 104 formed on the surface of the first barrier layer 103 and the lower sidewall and bottom of the silicon hole structure 102;

[0062] a second barrier layer 105 covering the surface of the polysilicon layer 104;

[0063] The electrode structure includes a first electrode used to lead out the polysilicon layer 104 and a second electrode used to lead out the silicon substrate 101 .

[0064] The silicon substrate 101 is P-type doped or N-type doped, and the doping concentration is 10 18 ~10 20 / cm 3 , and the doping type of the polysilicon layer 104 is the same as that of the silicon subs...

Embodiment 2

[0087] like Figure 10 As shown, this embodiment provides a method for monitoring the axial stress introduced by electroplating copper-filled silicon hole structure, including the steps: first step, first provide the polysilicon stress sensor as described in embodiment 1, using the conventional needle pressing method, First press the probes on the first pad and the second pad respectively, connect the polysilicon layer (force sensitive resistor) and three additional metal resistors to form a bridge, and test the previous value output of the bridge; In the first step, in the silicon hole structure of the polysilicon stress sensor, after using methods such as electroplating to fill copper 110, then press the probes to the first pad and the second pad, and test the bridge after filling copper 110 By comparing the front value and the back value of the bridge, the axial stress introduced by the silicon hole structure during the copper electroplating process can be obtained by calcu...

Embodiment 3

[0089] like Figure 10 ~ Figure 11 As shown, this embodiment provides a method for monitoring the axial stress generated in the process of thinning the backside of the silicon hole structure to form the through-silicon via, including the steps: the first step, first providing the polysilicon stress sensor as described in Embodiment 1 In the silicon hole structure of the polysilicon stress sensor, copper 110 is filled by electroplating or other methods; in the second step, the probes are respectively pressed onto the first pad and the second pad by using a conventional needle pressing method , connect the polysilicon layer (force-sensitive resistor) with three additional metal resistors to form a bridge, and test the previous value output of the bridge; the third step is to thin the silicon substrate 101 of the polysilicon stress sensor, and pass The HF solution exposes the filled copper 110, and uses the conventional needle pressing method to press the probes onto the first pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com