Temperature compensation type optical fiber intelligent gasket

A technology of temperature compensation and optical fiber intelligence, which is applied in the field of monitoring, can solve problems such as low measurement accuracy, bolt failure, and bolt looseness, and achieve the effects of sealing the corrosive environment, improving measurement accuracy, and improving durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

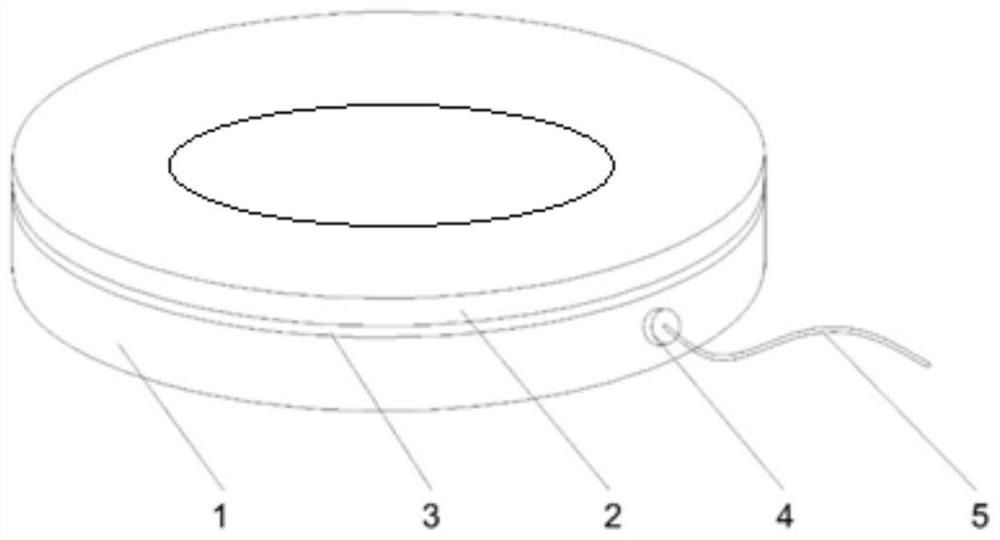

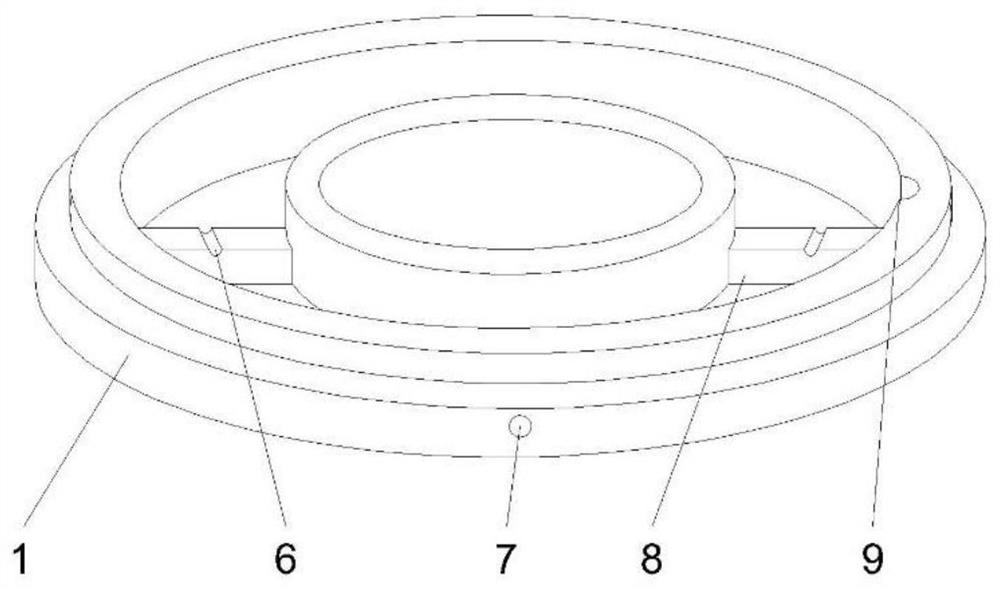

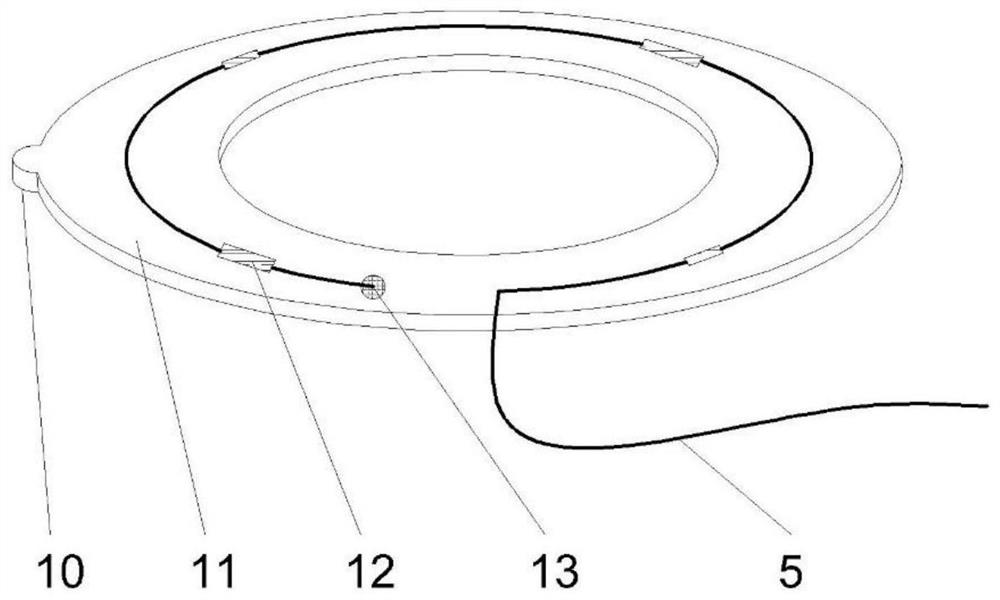

[0029] Such as Figure 1-4 As shown, a temperature-compensated optical fiber smart gasket disclosed in this embodiment includes a gasket base 1, and a supporting convex beam 8, a U-shaped groove 6, and a positioning groove 9 are designed on the gasket base 1; Cover 2, gasket upper cover 2 is designed with contact 14; elastic ring 11, elastic ring 11 is designed with positioning boss 10, optical fiber strain sensor 12 and optical fiber temperature sensor 13 are connected by optical fiber 5, installed on elastic ring 11; optical fiber 5 passes through the sealing plug 4.

[0030] The hardness and elastic modulus of the material used for the gasket upper cover 2 are much higher than those of the gasket base 1, so that when the gasket is stressed, the deformation of the gasket upper cover 2 is extremely small, and the main deformation of the gasket is uniform. Forced deformation from gasket base 1.

[0031] The elastic ring 11 is installed between the supporting beam 8 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com