Rapid retest device and test method for shear wave velocity of site formation

A shear wave and stratigraphic technology, applied in measuring devices, geophysical surveying, seismology, etc., can solve problems such as waste of manpower, time and economic costs, incomplete waveforms recorded by receivers, interlayers and interbedded phenomena in strata , to achieve fast testing, reduce human error, and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

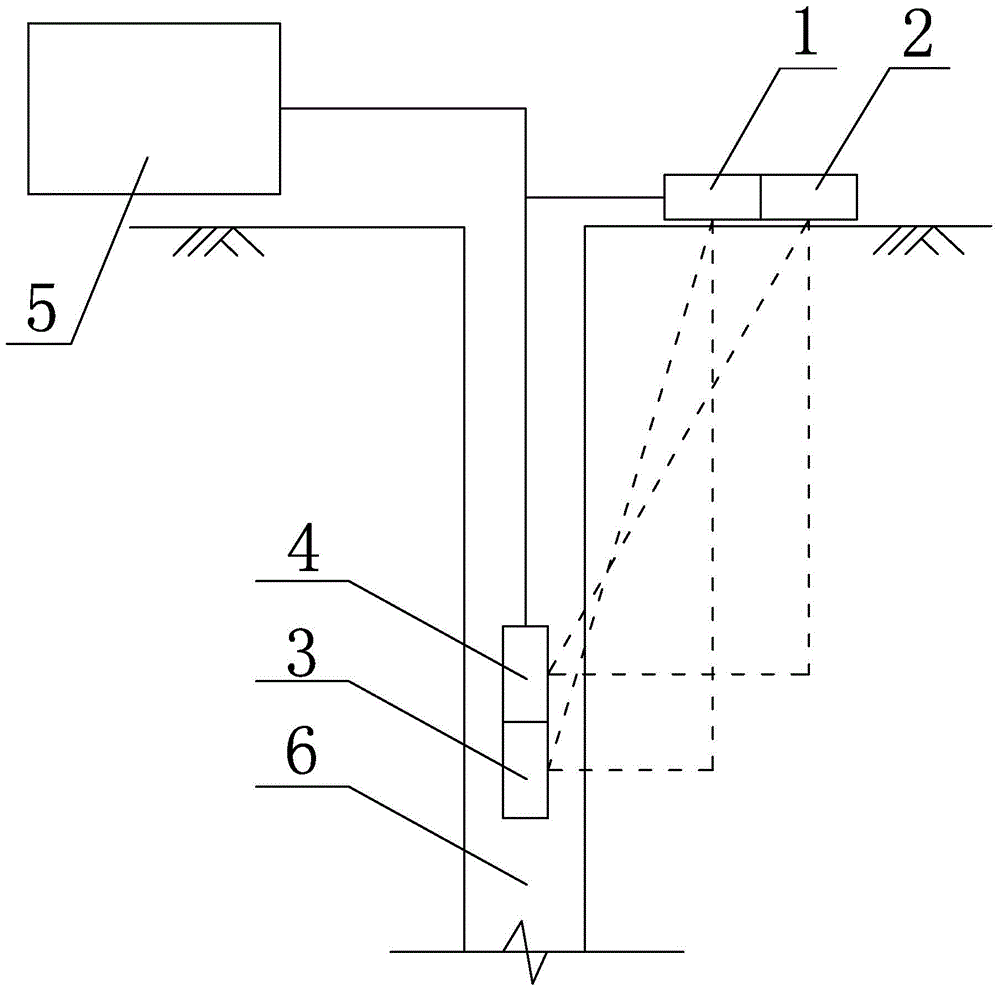

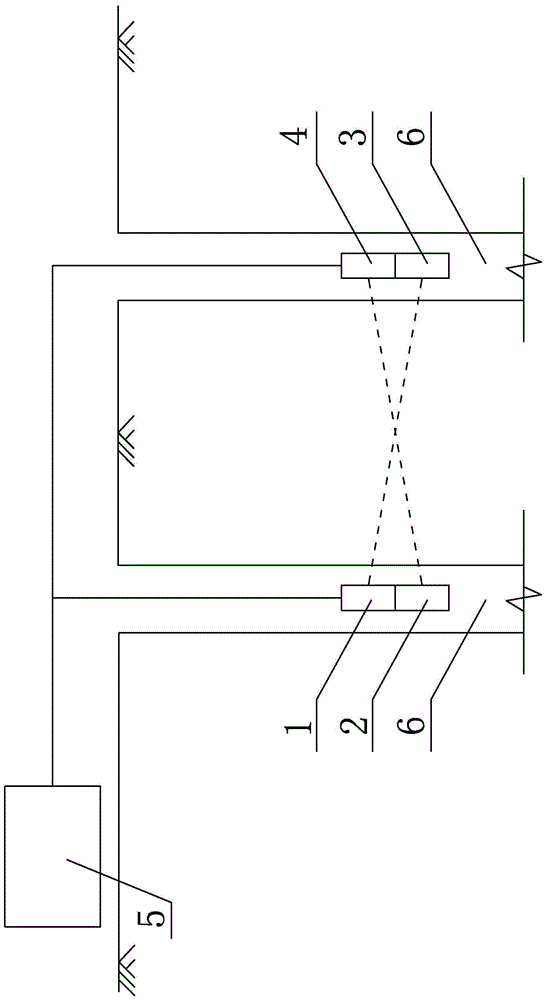

[0024] Such as figure 1 As shown, the rapid re-measurement device for the shear wave velocity of the site formation in this embodiment is based on the improvement of the conventional shear wave velocity test device. A vibration source generator 1 corresponds to the first wave detector 2, and the second wave detector 3 and the second vibration source generator 4 are connected side by side as a whole, and are respectively connected to the first vibration source generator 1 and the first vibration source generator 4 through signal lines. The computer connected to the geophone 2, the second geophone 3 and the second vibration source generator 4; the distance from the midpoint of the first vibration source generator 1 to the midpoint of the first geophone 2 and the midpoint of the second geophone 3 The distance to the second vibration source generator 4 midpoints is equal to Δx; the computer 5 can realize the control of different equipment (the first vibration source generator, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com