Method for steel production contract plan and multi-level inventory matching optimization under MTO-MTS management mode

A technology of inventory matching and production planning, which is applied in the fields of management science and engineering, and can solve problems such as lack of consideration of capacity balance, failure to fully utilize remaining inventory, and large contract surplus materials.

Active Publication Date: 2014-10-29

SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

View PDF2 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] 1. Failure to reasonably coordinate the contradiction between product customization and rapid production response from a global perspective;

[0005] 2. Failure to give full play to the remaining inventory, especially the impact of semi-finished product inventory on the production plan in the current planning outlook period, greatly restricting the flexibility of contract planning;

[0006] 3. When arranging the production plan according to the production capacity of the unit, there is a lack of consideration for the balance of production capacity

However, the above research is only based on the joint optimization of production and inventory based on finished product inventory matching, without considering the coordination effect of semi-finished product inventory on pro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

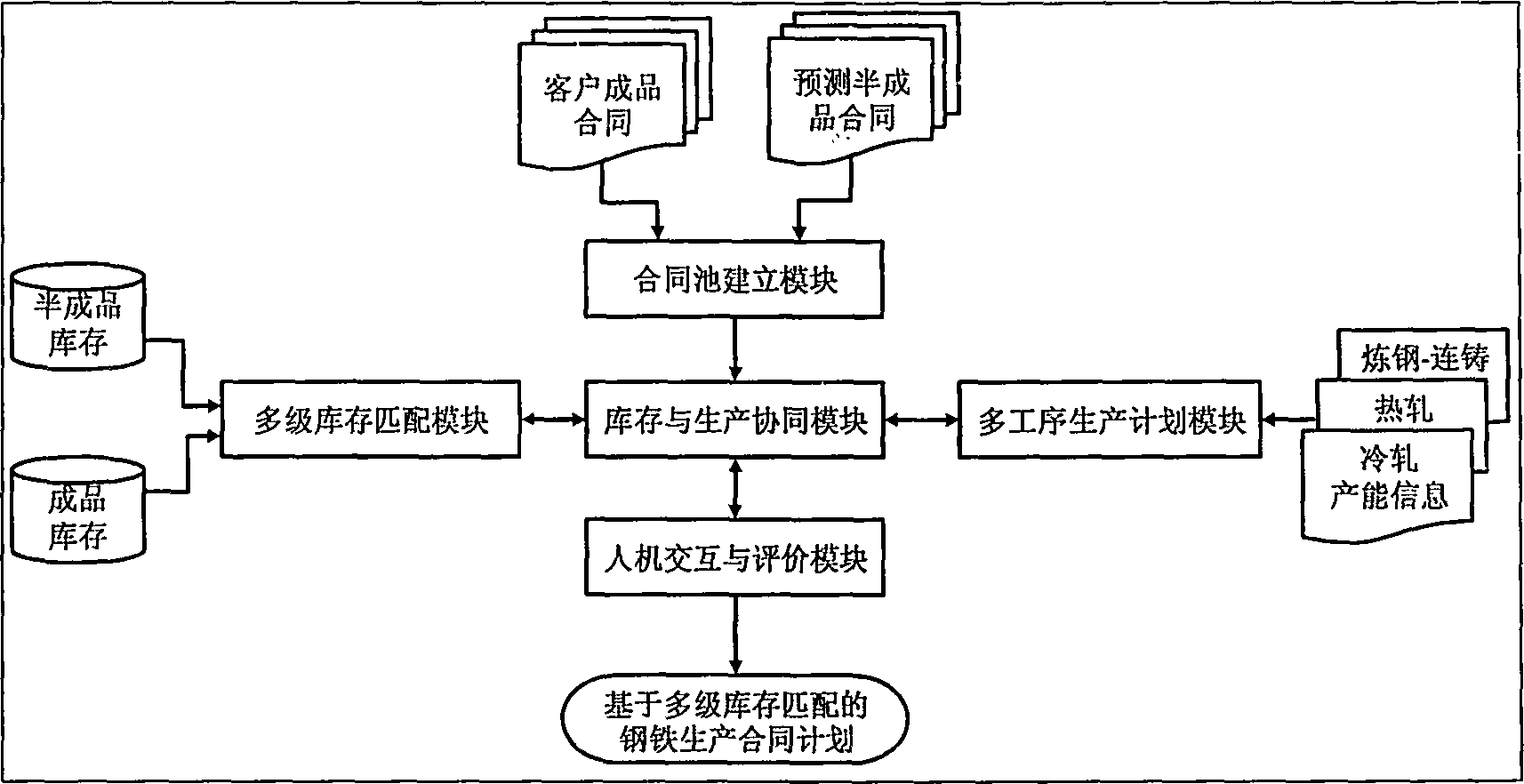

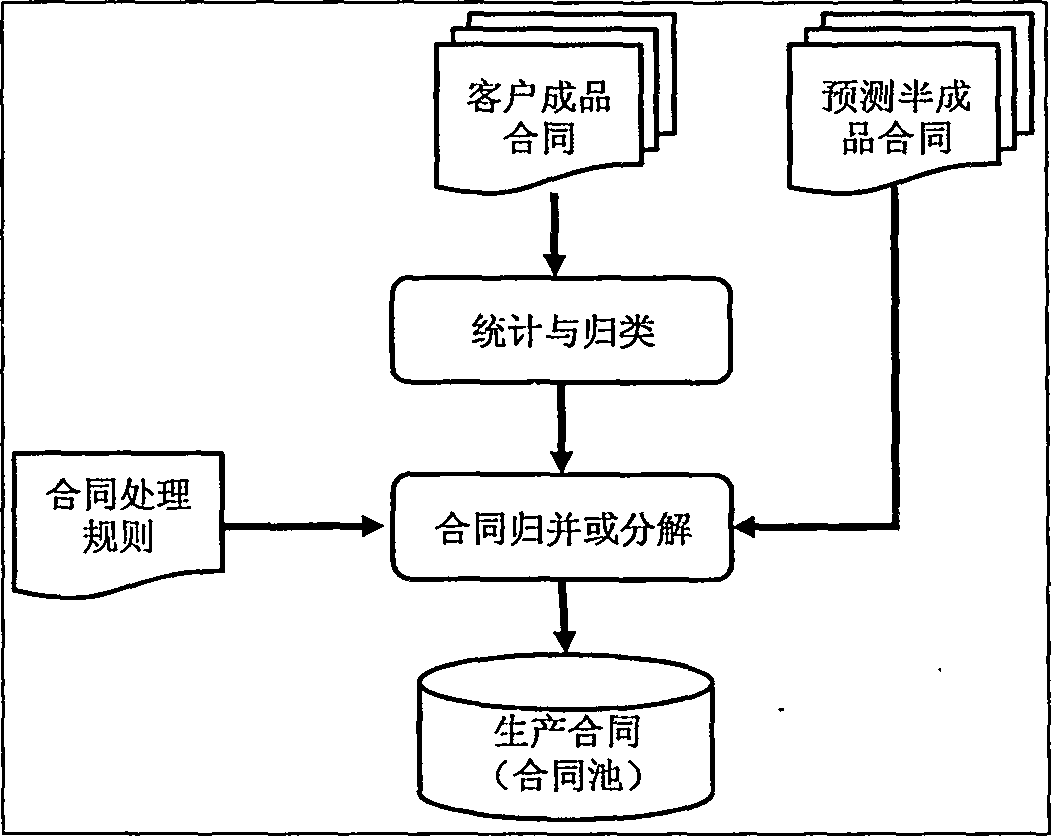

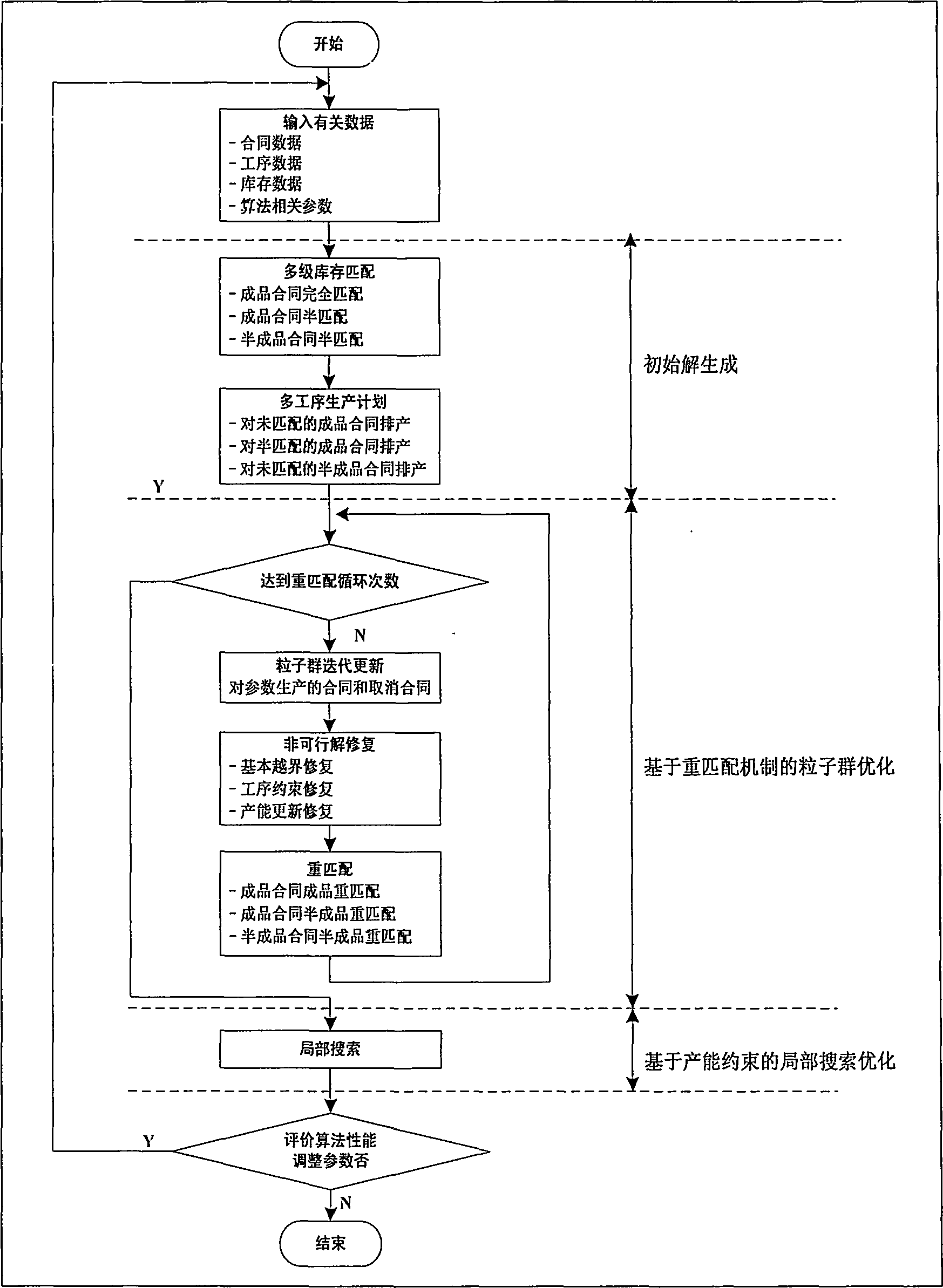

The invention belongs to the field of management science and engineering and particularly relates to a steel production contract plan compilation method based on multi-level inventory matching under an MTO-MTS mixed production mode. A logical frame of the method is composed of five modules which are a contract pool establishing module, a multi-level inventory matching module, a multi-process production plan module, an inventory and production collaboration module and a human-computer interaction and evaluation module, wherein the inventory and production collaboration module is a system core, a multi-level inventory and production plan joint optimization algorithm based on a rematch collaboration strategy is adopted for the inventory and production collaboration module, and the contract plan compilation problem under a mixed mode is solved by being combined with parameters coming from the human-computer interaction and evaluation module and coordinating the multi-level inventory matching module and the multi-process production plan module according to the output of the contract pool establishing module. The method is based on an operational research model and an intelligent algorithm, is the contract plan compilation method based on multi-level inventory matching and has important theoretical significance and wide application values for improving flexibility of a steel enterprise production management system.

Description

technical field [0001] The invention belongs to the field of management science and engineering, relates to the application of operations research modeling and intelligent optimization algorithms, and in particular relates to a contract planning method for iron and steel enterprises based on multi-level inventory matching in a mixed process production mode. Background technique [0002] With the development of information technology, the production management level of most domestic iron and steel enterprises has been greatly improved, but the drafting of contract plans is still at a relatively backward level. During the planned economy, most enterprises adopt MTS (Make to Stock), an inventory-oriented preparation method. According to the distribution of remaining inventory and on the basis of inventory matching, they arrange production for unmatched contracts. In order to meet order demand factors such as contract delivery date, customer importance, contract steel grade, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06Q10/04G06Q50/04

CPCY02P90/30

Inventor 张涛张琦琪

Owner SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com