Dye-sensitized solar cell ion electrolyte

A solar cell, dye sensitization technology, applied in the field of battery electrolyte and its preparation, can solve the problems of difficult packaging, easy volatilization and easy leakage of the electrolyte, and achieve the effect of overcoming volatilization and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

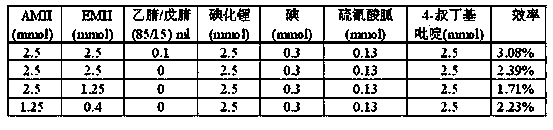

Embodiment 1

[0039] The components contained in the electrolyte in this example are: 1-ethyl-3-methylimidazolium iodine (denoted as EMII), 1-allyl-3-methylimidazolium iodine (denoted as AMII), iodine, 4 - tert-butylpyridine, guanidinium thiocyanate, lithium iodide, the solvent adopts the solvent that acetonitrile / valeronitrile is mixed by volume percentage 85 / 15.

[0040] The dosage of each component used in each group of experiments is respectively:

[0041] 1. 0.2976g of 1-ethyl-3-methylimidazolium iodine, 0.3126g of 1-allyl-3-methylimidazolium iodine, 0.0397g of iodine, 0.1690g of 4-tert-butylpyridine, and 0.0074g of guanidine thiocyanate , lithium iodide 0.2348g. Acetonitrile / valeronitrile (85 / 15) 0.1ml. See attached table 1 for photoelectric conversion efficiency.

[0042] 2. 0.2976g of 1-ethyl-3-methylimidazolium iodine, 0.3126g of 1-allyl-3-methylimidazolium iodine, 0.0397g of iodine, 0.1690g of 4-tert-butylpyridine, and 0.0074g of guanidine thiocyanate , lithium iodide 0.2348...

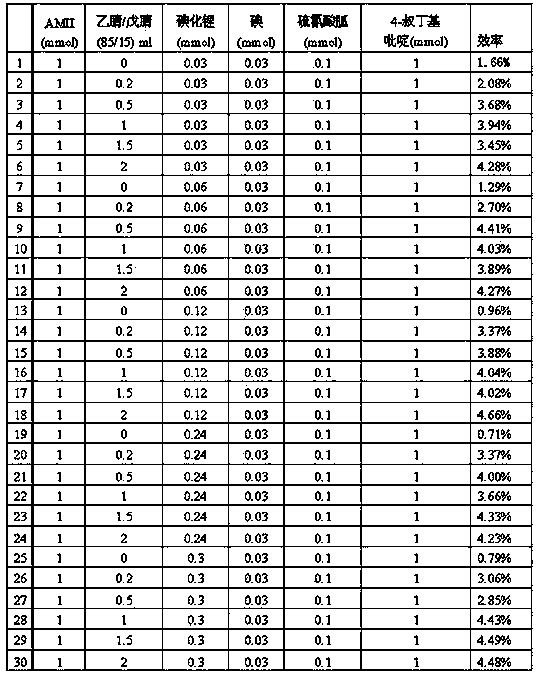

Embodiment 2

[0048] The components contained in the electrolyte in this example are: 1-ethyl-3-methylimidazolium iodine (denoted as EMII), 1-allyl-3-methylimidazolium iodine (denoted as AMII), iodine, 4 - tert-butylpyridine, guanidinium thiocyanate, lithium iodide, the solvent adopts the solvent that acetonitrile / valeronitrile is mixed by volume percentage 85 / 15.

[0049] The dosage of each component used in each group of experiments is respectively:

[0050] 1. 0.2387g of 1-ethyl-3-methylimidazolium iodine, 0.0076g of iodine, 0.1352g of 4-tert-butylpyridine, 0.0118g of guanidine thiocyanate, and 0.0094g of lithium iodide. See attached table 2 for photoelectric conversion efficiency.

[0051] 2. 0.2387g of 1-ethyl-3-methylimidazolium iodine, 0.0076g of iodine, 0.1352g of 4-tert-butylpyridine, 0.0118g of guanidine thiocyanate, and 0.0094g of lithium iodide. Acetonitrile / valeronitrile (85 / 15) 0.5ml. See attached table 2 for photoelectric conversion efficiency.

[0052] 3. 0.1694g of 1-et...

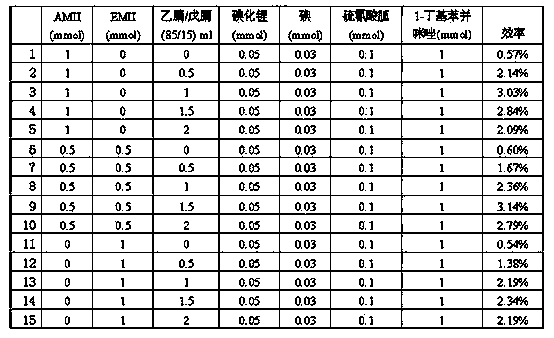

Embodiment 3

[0059] The components contained in the electrolyte in this group of examples are: 1-ethyl-3-methylimidazolium iodine (denoted as EMII), 1-allyl-3-methylimidazolium iodine (denoted as AMII), iodine, 4-tert-butylpyridine, guanidinium thiocyanate, lithium iodide, the solvent is acetonitrile / valeronitrile mixed solvent of 85 / 15 by volume.

[0060] The dosage of each component used in each group of experiments is respectively:

[0061] 1. 0.2501g of 1-allyl-3-methylimidazolium iodine, 0.0076g of iodine, 0.1352g of 4-tert-butylpyridine, 0.0118g of guanidine thiocyanate, and 0.0056g of lithium iodide. See attached table 3 for photoelectric conversion efficiency.

[0062] 2. 0.2501 g of 1-allyl-3-methylimidazolium iodine, 0.0076 g of iodine, 0.1352 g of 4-tert-butylpyridine, 0.0118 g of guanidine thiocyanate, and 0.0056 g of lithium iodide. Acetonitrile / valeronitrile (85 / 15) 0.2ml. See attached table 3 for photoelectric conversion efficiency.

[0063] 3. 0.2501 g of 1-allyl-3-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com