Heat absorption and ultraviolet radiation prevention glass and processing technology thereof

A technology of anti-ultraviolet radiation and processing technology, which is applied in the field of heat-absorbing anti-ultraviolet radiation glass and its processing technology, can solve the problems of low total solar energy transmittance, low infrared energy transmittance, low ultraviolet transmittance, etc., and achieve Resistant to interface defects, improving dispersion stability, and overcoming volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

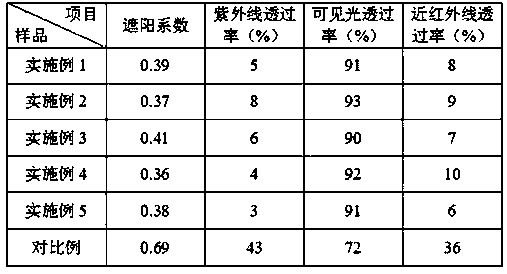

Examples

Embodiment 1

[0057] A heat-absorbing and anti-ultraviolet radiation glass, the heat-absorbing and anti-ultraviolet radiation glass includes a first glass body and a second glass body, the inner surface of the first glass body is sprayed with a heat-absorbing and anti-ultraviolet radiation layer, and the outer surface is sprayed with a high thermal conductivity material layer .

[0058] The heat-absorbing anti-ultraviolet radiation layer includes the following components in parts by weight: 10 parts of FeO, 20 parts of benzotriazole, 5 parts of Span-60, 1 part of polydimethylsiloxane, nano-titanium dioxide graft copolymer 30 parts and 100 parts of water, wherein the nano-titanium dioxide graft copolymer is a nano-titanium dioxide, acrylate monomer and fluorine-containing monomer graft copolymer.

[0059] The high thermal conductivity material layer includes the following components in parts by weight: 10 parts of boron nitride powder, 1 part of boron nitride nanosheet, 10 parts of graphite ...

Embodiment 2

[0078] A heat-absorbing and anti-ultraviolet radiation glass, the heat-absorbing and anti-ultraviolet radiation glass includes a first glass body and a second glass body, the inner surface of the first glass body is sprayed with a heat-absorbing and anti-ultraviolet radiation layer, and the outer surface is sprayed with a high thermal conductivity material layer .

[0079] The heat-absorbing ultraviolet radiation protection layer includes the following components in parts by weight: 12 parts of CuO, 22 parts of 2,4-dihydroxybenzophenone, 7 parts of Span-80, 1.5 parts of polydimethylsiloxane, nano 35 parts of titanium dioxide graft copolymer and 110 parts of water, wherein the nanometer titanium dioxide graft copolymer is nanometer titanium dioxide, acrylate monomer and fluorine-containing monomer graft copolymer.

[0080] The high thermal conductivity material layer includes the following components in parts by weight: 12 parts of boron nitride powder, 2 parts of boron nitride...

Embodiment 3

[0099] A heat-absorbing and anti-ultraviolet radiation glass, the heat-absorbing and anti-ultraviolet radiation glass includes a first glass body and a second glass body, the inner surface of the first glass body is sprayed with a heat-absorbing and anti-ultraviolet radiation layer, and the outer surface is sprayed with a high thermal conductivity material layer .

[0100] The heat absorbing anti-ultraviolet radiation layer includes the following components in parts by weight: 15 parts of calcium hexaboride, 25 parts of resorcinol monobenzoate, 10 parts of Tween-60, 2 parts of polydimethylsiloxane, 40 parts of nano-titanium dioxide graft copolymer and 120 parts of water, wherein the nano-titanium dioxide graft copolymer is a graft copolymer of nano-titanium dioxide, acrylate monomer and fluorine-containing monomer.

[0101] The high thermal conductivity material layer includes the following components in parts by weight: 15 parts of boron nitride powder, 3 parts of boron nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com