Cooling structure of permanent magnet motor

A cooling structure, permanent magnet motor technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of lowering the insulation level of the motor, lowering the usage rate, and high surface temperature of the motor housing, and reducing the heat loss, ensure permanence, provide work efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

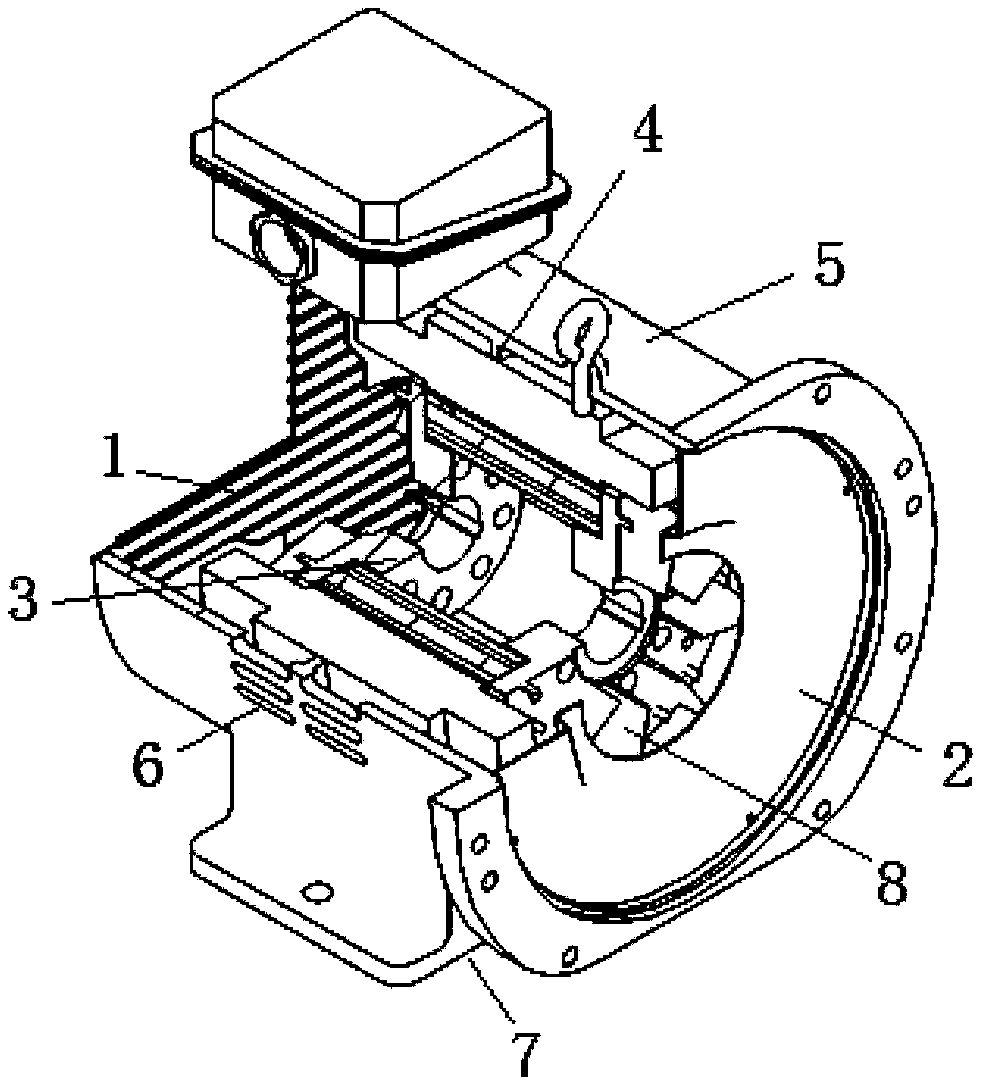

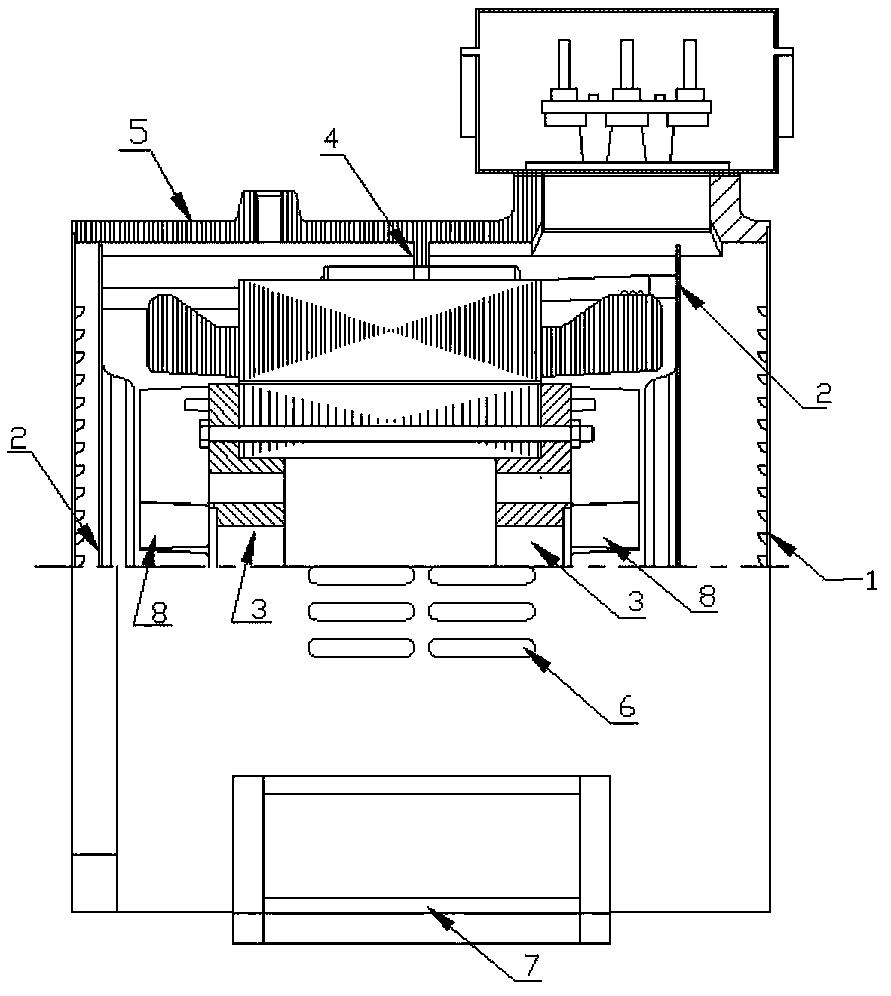

[0016] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a motor housing 5; in the motor housing 5: a protective air suction plate 1, two inlet deflectors 2, a side air outlet 6, an air exhaust port 7, an annular retaining ring 4 and Two rotating part cover plates 3; the protective suction plate 1 is located at the rear end of the motor housing 5 to absorb the surrounding cooling air and prevent foreign matter from entering the motor housing; the two inlet deflectors 2 are respectively located at the front and rear ends of the motor housing 5, one of which is located inside the protective air suction plate 1, and two inlet deflectors 2 are used to absorb cooling air around the motor; the side air outlet 6 is located at the motor housing The side of the body 5 is used to generate wind pressure in the flow channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com