A torque motor with positive magnetic spring stiffness

A torque motor and magnetic spring technology, applied in the field of rotary electro-mechanical converters, can solve problems such as difficult rotor stability, achieve the effects of reducing energy loss, reducing eddy current loss, and improving electromagnetic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

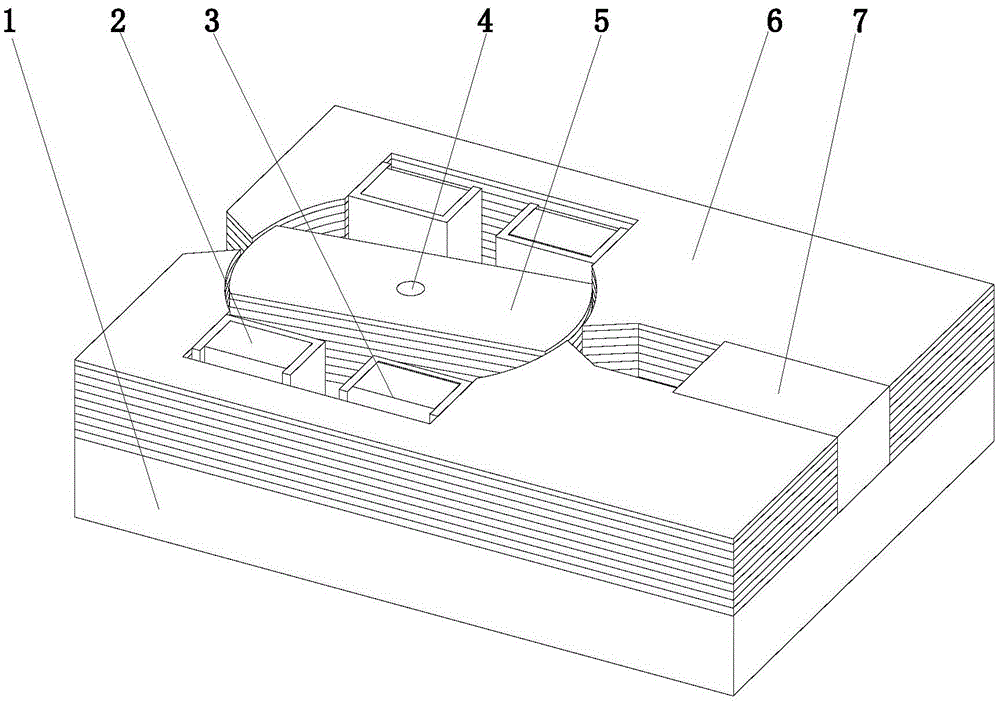

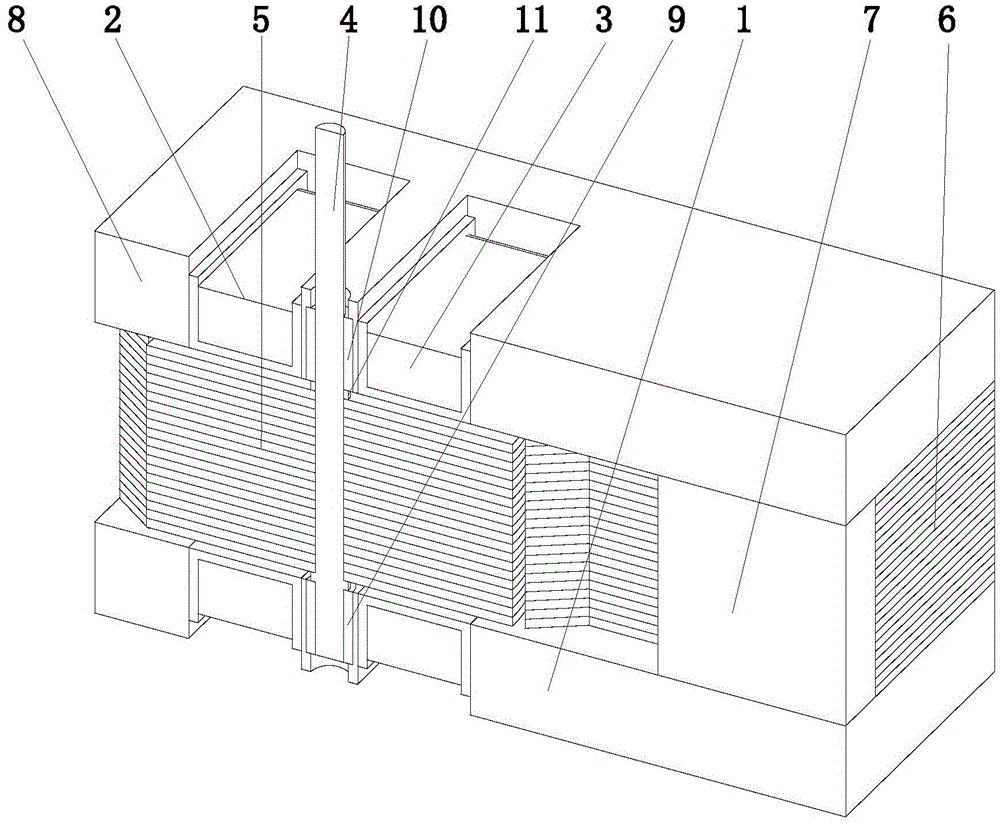

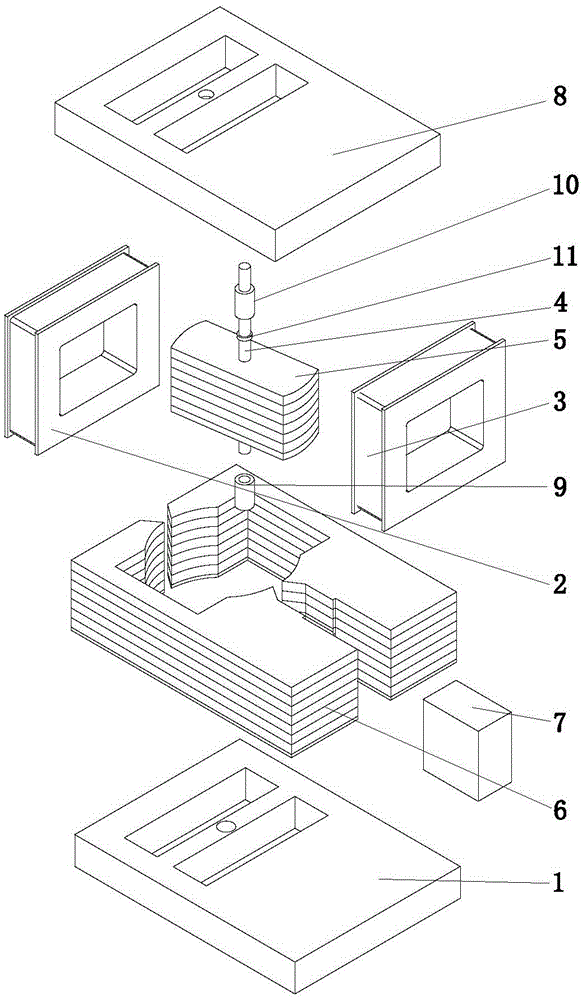

[0025] Example. A torque motor with positive magnetic spring stiffness, constructed as Figure 1-3 As shown, it includes bottom plate 1, coil winding A2, coil winding B3, output shaft 4, rotor 5, yoke iron 6, permanent magnet 7, top plate 8, bearing a9, bearing b10, sleeve 11, fixed on bottom plate 1 and top plate 8 The yoke 6 between is divided into a left yoke 61 and a right yoke 62, and the pole shoe surfaces of the left yoke 61 and the right yoke 62 form an isosceles trapezoidal air gap 12; one side of the left yoke 61 and the right yoke 62 The formed cavity is equipped with a permanent magnet 7, and two parallel coil windings A2 and B3 are installed in the cavity formed on the other side, and the inner cavity of the coil winding A2 and the coil winding B3 is fixed on the output shaft 4 The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com