Filling unit for packaging machines

A filling device and packaging machine technology, applied in the direction of packaging, cocks including cutting devices, valve devices, etc., can solve problems such as hindering the movement of the slide, pollution of the packaging machine, and delivery to the outside, so as to improve the overall capacity and bag unloading performance The effect of improving and improving the accuracy of bag unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

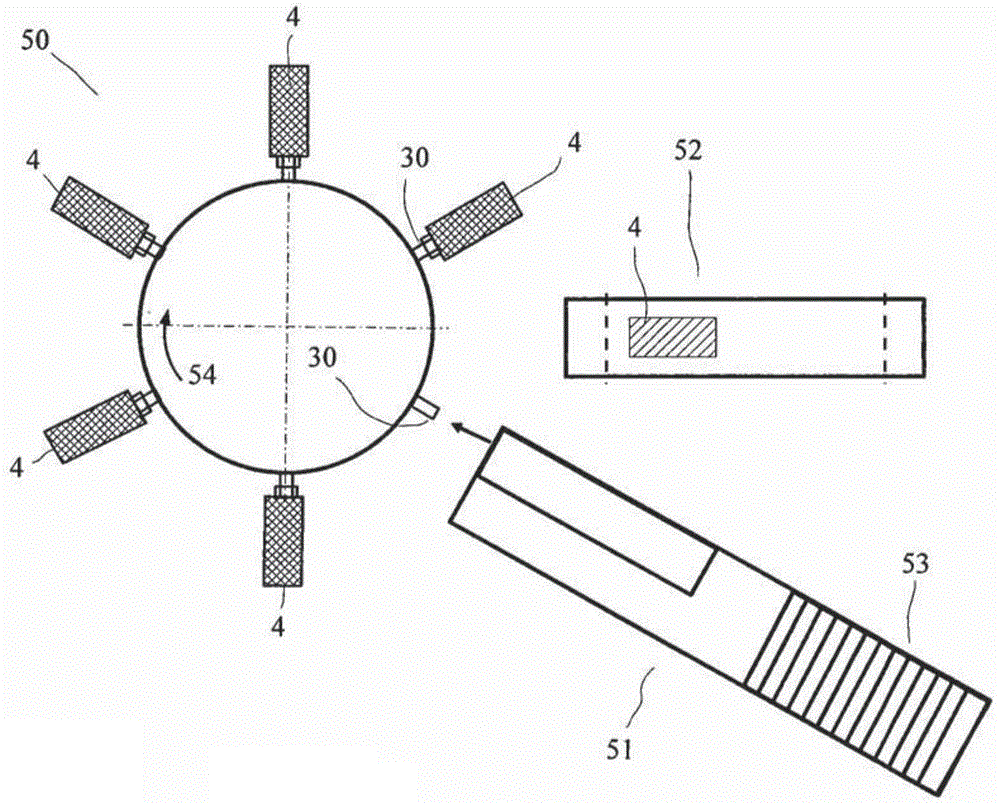

[0042] figure 1 A simplified top view of a packaging machine 50 for filling bulk material into valve pockets according to the present invention is shown. For example, the valve bag 4 is filled with cement with a packing machine 50 .

[0043] Packaging machine 50 rotates clockwise in the direction of arrow 54 . The automatic bag inserting machine 51 is arranged on a suitable angle position, removes the valve pockets 4 from the bag stack 53 and automatically ejects a valve pocket 4 onto the rotating filling nozzle 30 respectively.

[0044] During the continuous rotation process, the valve bag 4 is filled with the material to be filled. Filling is first performed at a high flow rate until a predetermined weight threshold is reached. Filling then takes place at low flow rates until the final weight is reached. This can be followed by a compacting phase until reaching a corner with a discharge belt onto which the filled valve bag is discharged. The weight of the valve bag 4 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com