Self-compacting concrete and preparation method thereof

A self-compacting concrete and stone technology, applied in the field of building materials, can solve the problem that the compressive strength of self-compacting concrete cannot meet the requirements of concrete compressive strength, and achieve the goal of improving self-compacting performance, compressive strength and fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

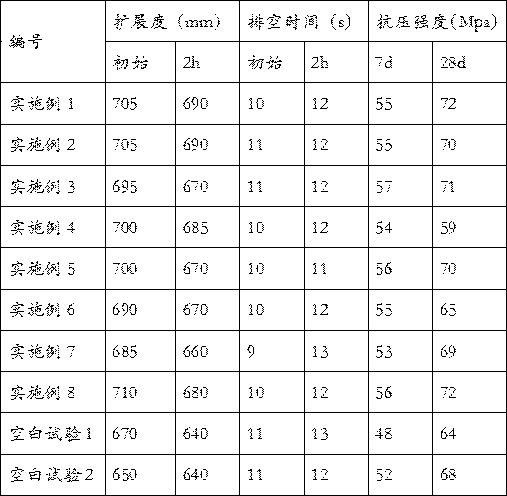

Examples

Embodiment 1

[0046] A self-compacting concrete, comprising the following components per cubic meter of self-compacting concrete:

[0047] 155kg of water;

[0048] Cement 360 kg;

[0049] Sand material 750 kg;

[0050] Stone 980 kg;

[0051] Mineral admixture 160 kg;

[0052] Admixture 6 kg;

[0053] Ultrafine powder 2 kg;

[0054] Modifier 2 kg.

[0055] Among them, the cement is p.042.5 cement, and the sand material is low-alkali active mechanism sand with a fineness modulus of 2.3; the stone material is two gradations of 5-16mm and 5-25mm low-alkali active machine-made crushed stone mixture, and the two The weight ratio of the two is 1:1; the mineral admixture is a mixture of Class I fly ash and S75 mineral powder, and the weight ratio of the two is 2:1; the admixture is a polycarboxylic acid regulator; the ultrafine powder is two Tin oxide; modifiers include absolute ethanol and fluorocarboxylic acid, the weight ratio of the two is 5:2.

[0056] Its preparation method is:

[00...

Embodiment 2

[0062] A self-compacting concrete, comprising the following components per cubic meter of self-compacting concrete:

[0063] 160kg of water;

[0064] 400 kg of cement;

[0065] Sand material 800 kg;

[0066] Stone 960 kg;

[0067] Mineral admixture 180 kg;

[0068] Admixture 6 kg;

[0069] Ultrafine powder 1 kg;

[0070] Modifier 2 kg.

[0071]Among them, the cement is p.042.5 cement, and the sand material is low-alkali active mechanism sand with a fineness modulus of 2.5; the stone material is two gradations of 5-16mm and 5-25mm low-alkali active machine-made crushed stone mixture, and the two The weight ratio is 1:1; the mineral admixture is a mixture of Class I fly ash and S75 mineral powder, and the weight ratio of the two is 3:2; the admixture is a polycarboxylic acid regulator; the ultrafine powder is boron zirconium oxide; the modifying agent includes absolute ethanol and fluorinated carboxylic acid, and the weight ratio of the two is 5:2.

[0072] Its preparati...

Embodiment 3

[0078] A self-compacting concrete, comprising the following components per cubic meter of self-compacting concrete:

[0079] 170kg of water;

[0080] Cement 380 kg;

[0081] Sand material 700 kg;

[0082] Stone 970 kg;

[0083] Mineral admixture 200 kg;

[0084] Admixture 5 kg;

[0085] Ultrafine powder 3 kg;

[0086] Modifier 3 kg.

[0087] Among them, the cement is p.042.5 cement, and the sand material is low-alkali active mechanism sand with a fineness modulus of 2.8; the stone material is low-alkali active machine-made crushed stone mixture with two grades of 5-16mm and 5-25mm, and two The weight ratio of the two is 2:1; the mineral admixture is a mixture of Class I fly ash and S75 mineral powder, and the weight ratio of the two is 1:1; the admixture is a polycarboxylic acid regulator; the ultrafine powder is two Tin oxide; modifiers include absolute ethanol and fluorocarboxylic acid, the weight ratio of the two is 5:2.

[0088] Its preparation method is:

[0089]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com