A high-efficiency production line system and production process for laminated panels

A laminated board and production line technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of low utilization rate of mold table, single function, low production efficiency, etc., achieve long service life, increase strength, occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

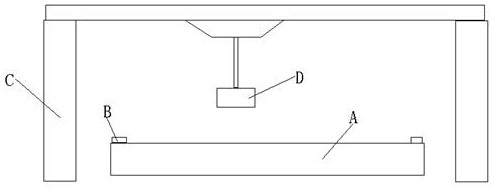

[0064] A laminated panel production line system includes a fixed mold table A, a positioning fixture B equipped on the fixed mold table A, and a mobile distributing device C installed in the space on both sides of the fixed mold table A.

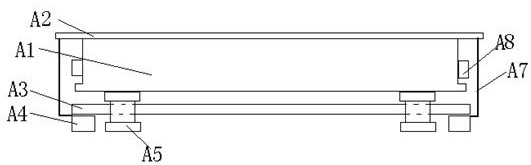

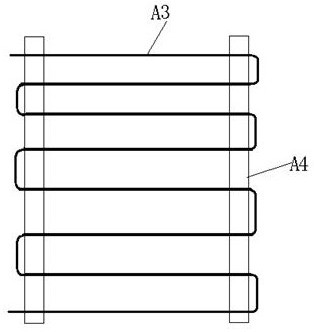

[0065] The fixed mold platform A includes a mold platform A1 and a bottom mold platform A2 that is flat and auxiliary on the upper surface of the mold platform A1. Several vibration motors A8 are fixedly installed around the mold platform A1. Several rubber springs A5 are supported, and the bottom of the mold base A1 is laid with a water heating pipeline A3, and the water heating pipeline A3 is erected off the ground through the ground support A4 and coiled on the bottom of the mold base A1; The surroundings of the mold base A1 are covered with insulation boards A7. The vibration motor A8 is fixedly installed on the side walls around the mold base A1, and its quantity is selected to be 4-8 depending on the size of the mold base; the rubber s...

Embodiment 2

[0070] A high-efficiency production process for laminated panels, comprising the following process steps:

[0071] S1. Preparation of concrete

[0072] Each cubic concrete is prepared by mixing the following raw materials in parts by weight;

[0073] 450 parts of cement, 1150 parts of graded gravel, 820 parts of machine-made sand, 4.5 parts of concrete shrinkage reducing agent, 9 parts of high-performance additives, and 150 parts of water;

[0074] S2. Pouring concrete

[0075] Prepare the mold table before pouring. When the surface temperature of the mold table is above 20°C, pour the concrete in S1 into the mold table; The surface temperature of the mold table is kept above 20°C; the vibration motor around the mold base is activated at the same time as pouring, and the mold base is under the joint action of the vibration motor and the rubber spring at the bottom to effectively improve the pouring efficiency of concrete.

[0076] S3, the first lamination

[0077] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com