Unfired self-compacting concrete and preparation method thereof

A self-compacting concrete, unilateral technology, applied in the field of concrete production, can solve the problems of poor self-compacting of non-fired concrete, and achieve the effect of avoiding the increase of liquid phase viscosity, improving dispersion and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

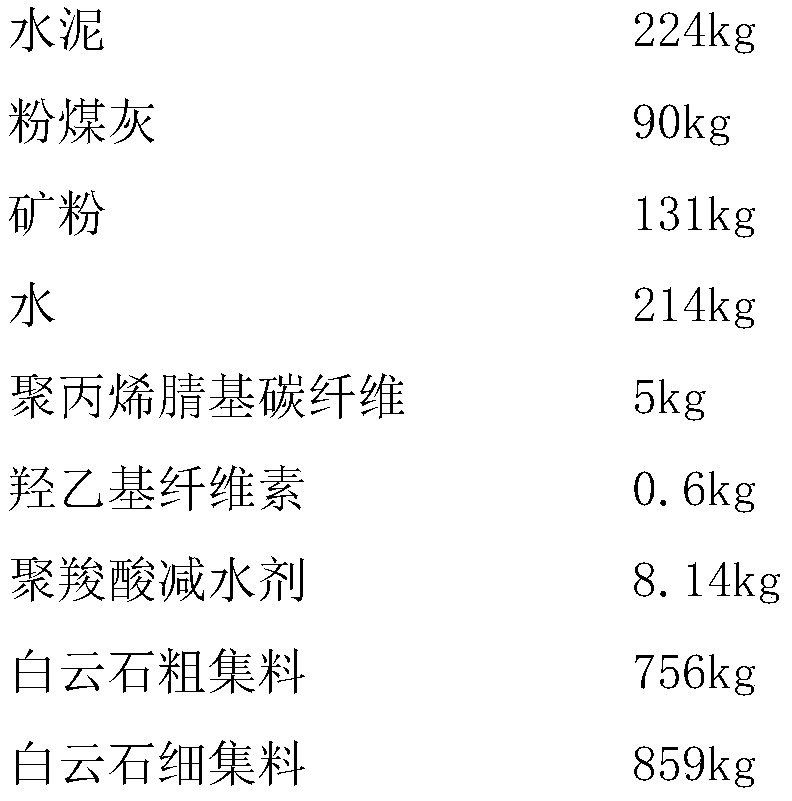

[0035] (1) Measure each raw material according to the following unilateral dosage ratio:

[0036]

[0037] Among them, the cement is P.OⅡ42.5R ordinary Portland cement, and its specific surface area is 373m 2 / kg, the initial setting time is 170min, the final setting time is 256min, the three-day compressive strength is 31.2MPa, and the 28d compressive strength is 50.1MPa.

[0038] The dolomite coarse aggregate is natural dolomite, CaCO 3 The content is 96.7%, and the particle size is continuously graded from 5 to 20 mm.

[0039] The fine aggregate is machine-made sand obtained after crushing natural dolomite, the stone powder content is 8%, and the fineness modulus is 2.67.

[0040] The fly ash is Class I fly ash of Class F, with a water demand ratio of 95% and a specific surface area of 430m 2 / kg, the mineral powder is S95 grade mineral powder, the specific surface area is 435m 2 / kg.

[0041] The polyacrylonitrile-based carbon fiber is a chopped fiber with a leng...

Embodiment 2

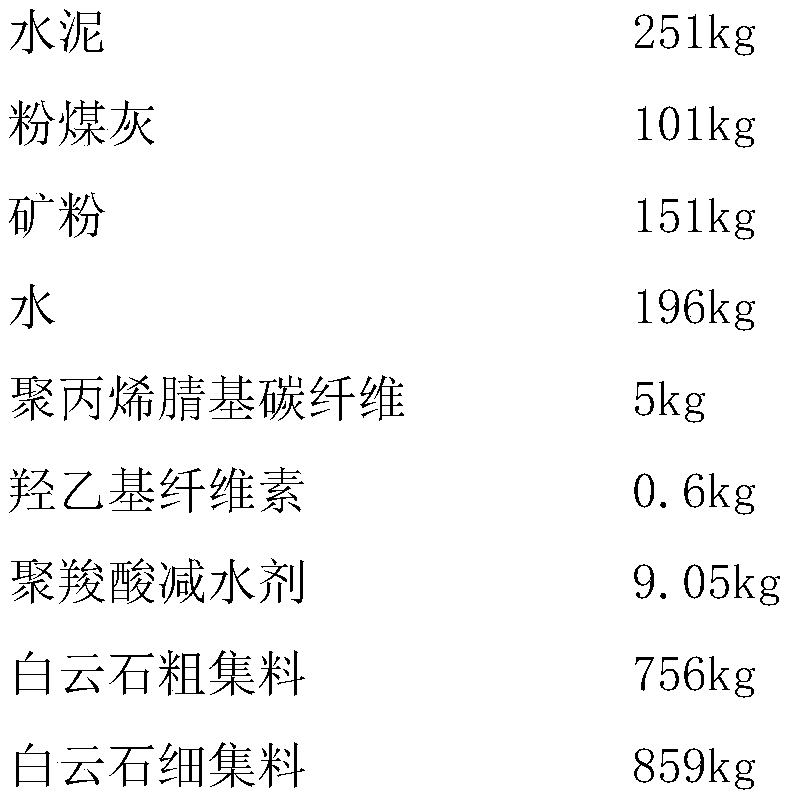

[0048] Design according to the same conditions as in Example 1, the difference is only: measure each raw material according to the following unilateral dosage ratio:

[0049]

Embodiment 3

[0051] Design according to the same conditions as in Example 1, the difference is only: measure each raw material according to the following unilateral dosage ratio:

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Initial setting time | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com