Ultra-dense concrete polycarboxylate water reducer for nuclear power and preparation method thereof

A water-reducing agent and super-dense technology, applied in the field of ultra-dense concrete polycarboxylate water-reducer for nuclear power and its preparation, can solve the adverse effects of concrete mechanical properties and durability, complex components, polycarboxylate water-reducer Problems such as adsorption-dispersibility and dispersion retention, to achieve the effect of improving self-compacting, improving fluidity, reducing equipment investment costs and energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

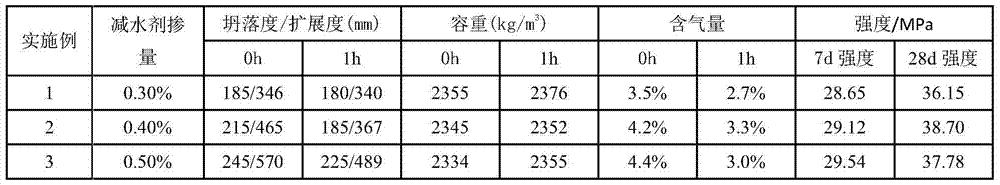

Examples

Embodiment 1

[0040] A polycarboxylate superplasticizer for nuclear power ultra-dense concrete, comprising the following components and parts by weight per 100 parts:

[0041]Dispersed ether polycarboxylate superplasticizer: 50 parts

[0042] Slump-preserving ether polycarboxylate superplasticizer: 20 parts

[0043] Sodium gluconate: 5 parts

[0044] Polyether modified silicone defoamer: 0.05 parts

[0045] Hydroxypropyl methylcellulose: 2 parts

[0046] Triethanolamine: 1 part

[0047] Sodium nitrite: 0.3 parts

[0048] water: balance

[0049] Among them, the dispersed ether polycarboxylate water reducer is prepared by the following method:

[0050] Add 180 g of TPEG macromonomer and 180 g of water into the reactor equipped with a stirring device at normal temperature, turn on the stirring device, and stir until the TPEG macromonomer is completely dissolved. Add 2.5 g of ammonium persulfate, 1 g of hydrogen peroxide (purity: 35%), and 3.3 g of acrylic acid to the reaction system, an...

Embodiment 2

[0054] A polycarboxylate superplasticizer for nuclear power ultra-dense concrete, comprising the following components and parts by weight per 100 parts:

[0055] Dispersed ether polycarboxylate water reducer: 52 parts

[0056] Slump-preserving ether polycarboxylate superplasticizer: 25 parts

[0057] Sodium gluconate: 3 parts

[0058] Polyether defoamer: 0.01 parts

[0059] Sodium tripolyphosphate: 3 parts

[0060] Triisopropanolamine: 1.5 parts

[0061] Sodium nitrite: 0.2 parts

[0062] water: balance

[0063] Among them, the dispersed ether polycarboxylate water reducer is prepared by the following method:

[0064] Add 180 g of TPEG macromonomer and 230 g of water into the reactor equipped with a stirring device at normal temperature, turn on the stirring device, and stir until the TPEG macromonomer is completely dissolved. Add 4 g of hydrogen peroxide (purity: 35%) and 2.3 g of maleic anhydride to the reaction system, and continue to fully stir the reaction system. ...

Embodiment 3

[0068] A polycarboxylate superplasticizer for nuclear power ultra-dense concrete, comprising the following components and parts by weight per 100 parts:

[0069] Dispersed ether polycarboxylate superplasticizer: 55 parts

[0070] Slump-preserving ether polycarboxylate superplasticizer: 20 parts

[0072] Polyether defoamer: 0.05 parts

[0073] Hydroxypropyl methylcellulose: 1 part

[0074] Triisopropanolamine: 1 part

[0075] Methylparaben: 0.2 parts

[0076] water: balance

[0077] Among them, the dispersed ether polycarboxylate water reducer is prepared by the following method:

[0078] Add 180 g of TPEG macromonomer and 200 g of water into the reactor equipped with a stirring device at normal temperature, turn on the stirring device, and stir until the TPEG macromonomer is completely dissolved. Add 2 g of potassium persulfate, 1 g of hydrogen peroxide (purity: 35%), and 2.5 g of maleic anhydride to the reaction system, and continue to full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com