Method for formulating cold rolling process of 5052 aluminum alloy plate and strip

A technology of aluminum alloy strip and process, applied in the direction of metal rolling, which can solve the problems of lack of rolling process and unfavorable direct use of rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

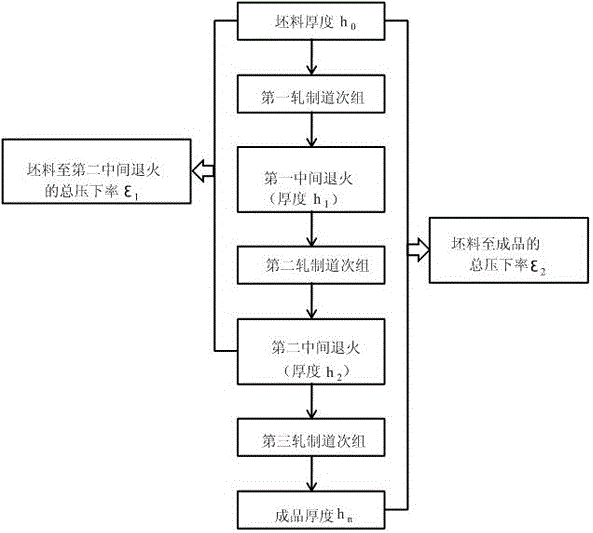

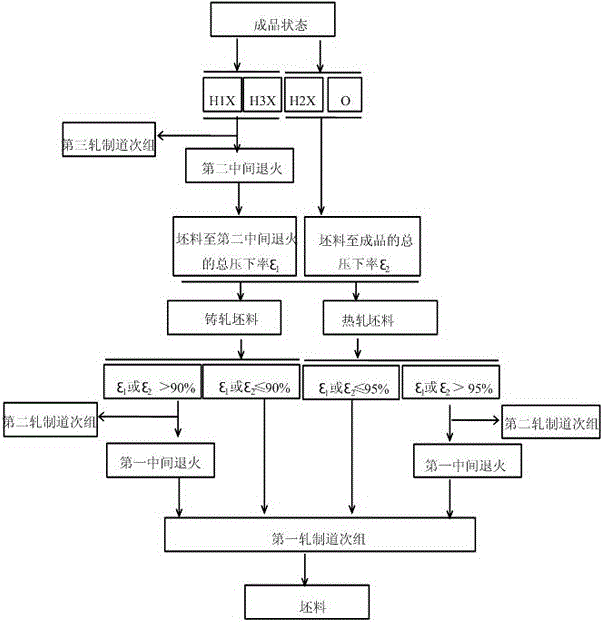

Method used

Image

Examples

Embodiment 1

[0126] exist 460mm / 1220mm×1850mm 4-roller reversible aluminum strip cold rolling mill cold-rolled 5052 aluminum alloy, cast-rolled billet thickness 7mm, width 1200mm, coil weight 4.5t. The thickness of the finished strip is required to be 0.4mm, and the finished state is H14.

[0127] The specific steps to formulate the cold rolling process are:

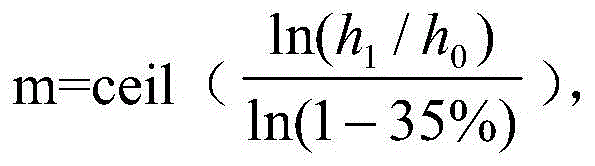

[0128] (1) If the finished product state is H14 state, the cold rolling process includes the second intermediate annealing and the third rolling pass group. The third rolling pass group includes 1 pass, and the total pass reduction rate ε of the third rolling pass group 0 25-45%, may wish to take ε 0 35%.

[0129] (2) According to the finished product thickness of 0.4mm and the total pass reduction rate of the third rolling pass group of 35%, calculate the intermediate annealing thickness h 2 = 0.62 mm. According to the billet thickness 7mm and the intermediate annealing thickness 0.62mm, calculate the total reduction ratio ε ...

Embodiment 2

[0138] exist 460mm / 1220mm×1850mm 4-roller reversible aluminum strip cold rolling mill cold-rolled 5052 aluminum alloy, the thickness of the cast-rolled billet was 5.5mm, the width was 1200mm, and the coil weight was 4.5t. The thickness of the finished strip is required to be 0.9mm, and the finished state is H16.

[0139] The specific steps to formulate the cold rolling process are:

[0140] (1) If the finished product state is H16 state, the cold rolling process includes the second intermediate annealing and the third rolling pass group. The third rolling pass group includes 2 passes, the pass reduction rate intervals of the 2 passes are 30-50% and 15-35% respectively, the total pass reduction rate of the third rolling pass group ε 0 45-65%. May wish to take ε 0 =55%, using the principle that the rolling pressure difference of each pass is the smallest, the reduction rates of the two passes are determined to be 35.00% and 30.77%, respectively.

[0141] (2) Calculate the...

Embodiment 3

[0148] exist 460mm / 1220mm×1850mm 4-roller reversible aluminum strip cold-rolling mill is used to cold-roll 5052 aluminum alloy. The thickness of the hot-rolled billet is 6.5mm, the width is 1200mm, and the coil weight is 5.5t. The thickness of the finished strip is required to be 0.2mm, and the finished state is H12.

[0149] The specific steps to formulate the cold rolling process are:

[0150] (1) If the finished product state is H12 state, the cold rolling process includes the second intermediate annealing and the third rolling pass group. The third rolling pass group includes 1 pass, take the total pass reduction rate ε of the third rolling pass group 0 10-35%. May wish to take ε 0 is 26.00%.

[0151] (2) According to the finished product thickness of 0.2mm and the total pass reduction rate of the third rolling pass group of 26%, calculate the intermediate annealing thickness h 2 = 0.27 mm. According to the billet thickness of 6.5mm and intermediate annealing thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com