Combined steel wire straightening method and apparatus thereof

A combined type, steel wire technology, applied in the field of metal product processing equipment, can solve the problems of difficult steel wire, low tensile strength, and inward shrinkage of steel wire, and achieve the effects of improving stability and pass rate, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing:

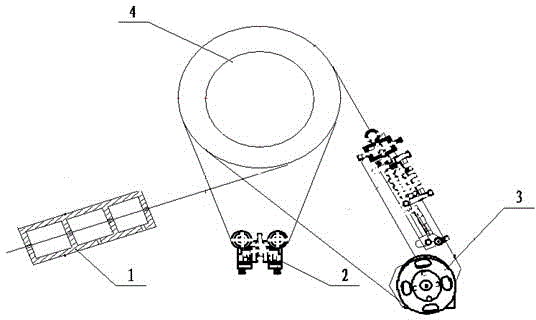

[0017] figure 1 Among them, the steel wire combined straightening device of the present invention is composed of a wire drawing die box 1, a horizontal group straightener 2, a joint straightener 3, and a reel 4; A horizontal set of straighteners 2 and a conjoined straightener 3 are arranged on the side of the barrel 4 .

[0018] The horizontal straightener 2 is a three-roller horizontal group straightener.

[0019] The horizontal group straightener 2 and the conjoined straightener 3 are arranged at an angle of 60-90° to each other.

[0020] The horizontal straightener 2 is set at a distance of 200-500 mm from the reel.

[0021] Steel wire combined straightening method: After the steel wire comes out of the mold box 1 and is put on the reel 4, after being straightened by the conjoined straightener 3, it is wound back to the reel 4, and the steel wire passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com