Assembly line type screw locking and adhesive dispensing double-station operating device

A working device and assembly-line technology, which is applied to the device for coating liquid on the surface, metal processing, manufacturing tools, etc., can solve the problems of long process, low sub-station processing work efficiency, poor accuracy, etc., to improve productivity, mechanism Simple and convenient, the effect of short working process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

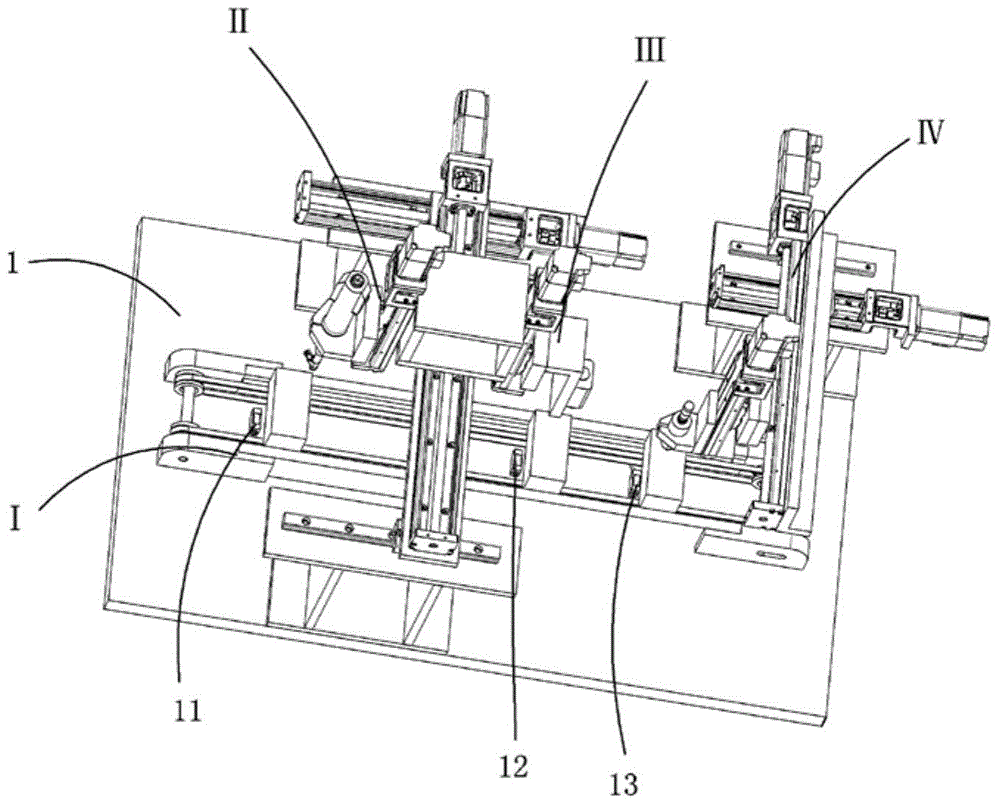

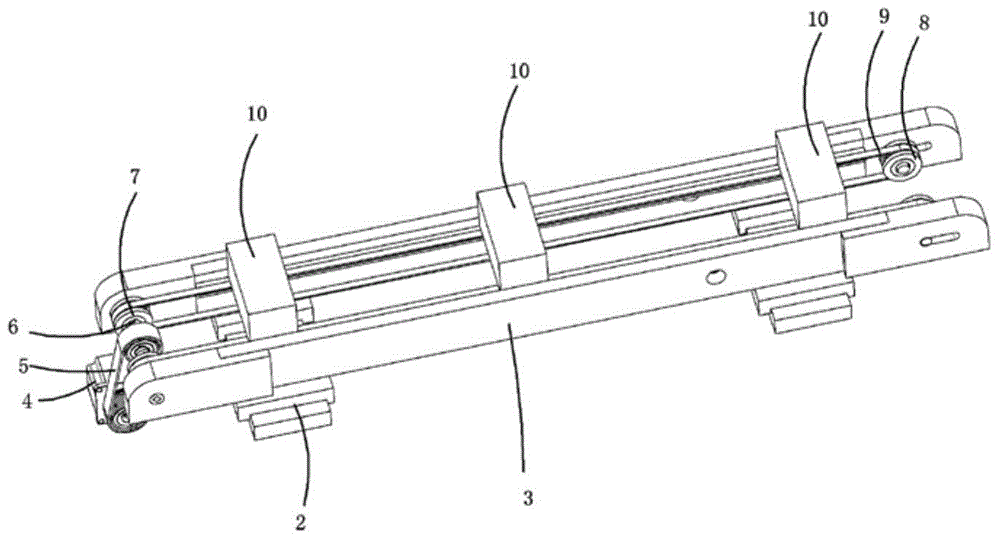

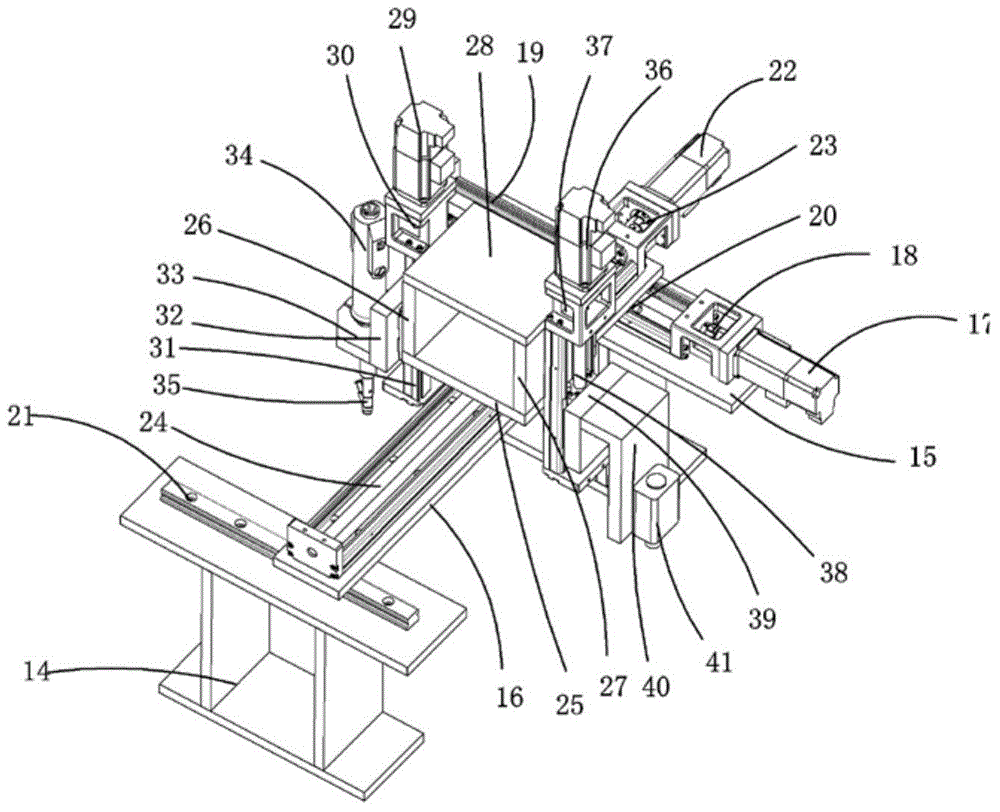

[0026] Examples, see attached Figure 1~4 , an assembly line screw locking and dispensing dual-station operating device, which includes a base plate 1, on which an assembly line device I, a screw locking device II, a CCD alignment detection mechanism III, and a glue dispensing mechanism IV are installed on the bottom plate. The assembly line device includes an assembly line base 2, an assembly line support plate 3, a driving motor 4, a belt 5, a driving shaft 6, a driving wheel 7, a driven wheel 8, a conveyor belt 9, a product 10, a photoelectric sensor a11, a photoelectric sensor b12 and a photoelectric sensor c13. The driving motor is installed on the bottom of the base plate, and the main shaft of the driving motor and the driving shaft are connected together by a belt; The shafts are connected together, two driving wheels are installed on the driving shaft, driven wheels are respectively installed on the right inner side of each set of assembly line support plates, each dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com