A kind of preparation method of glass fiber reinforced cross-linked polystyrene board

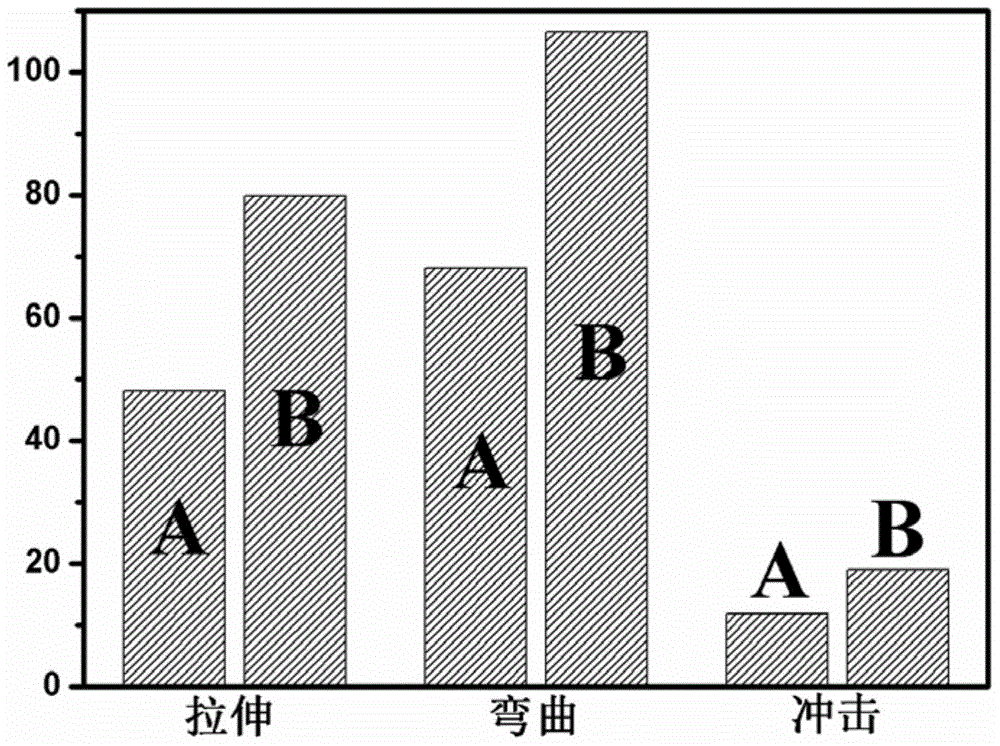

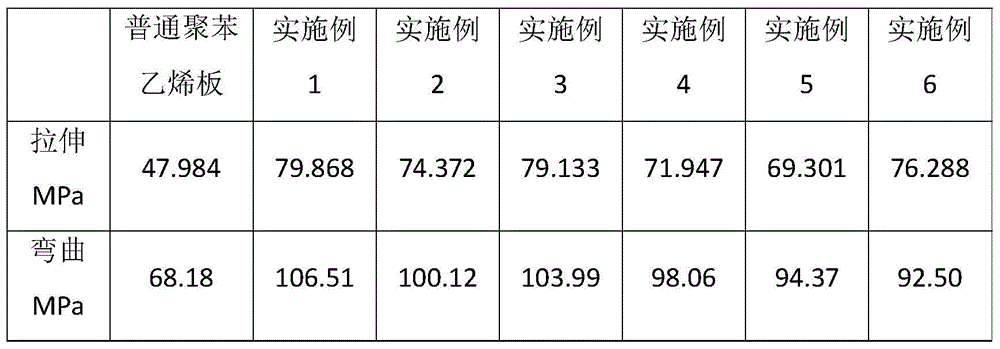

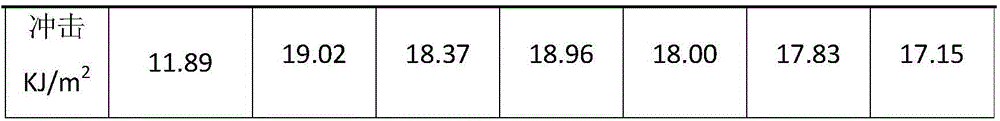

A technology of cross-linked polystyrene and polystyrene, which is applied in the field of efficient preparation of glass fiber reinforced cross-linked polystyrene boards, can solve the problems of insufficient mechanical strength of cross-linked polystyrene boards, achieve enhanced mechanical strength, and eliminate gaps , Improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of glass fiber reinforced cross-linked polystyrene plate, it comprises the following steps:

[0025] 1) Mix styrene and divinylbenzene evenly, prepare a mixed solution of the two, in which the styrene is 95-99wt%, and the divinylbenzene is 1-5wt%;

[0026] 2) Mix the polystyrene powder with the above mixed solution at a mass ratio of 1:1 to 9, and stir at high speed until the solution is clear and transparent;

[0027] 3) Pour the chopped glass fiber with a diameter of 5-15 μm and a length of 3-30 mm into the γ-(methacryloyloxy)propyltrimethoxysilane (MPS) solution, take it out after soaking for 1 hour, and use a deionized Rinse with water to neutral, dry;

[0028] 4) Add the chopped glass fiber treated with the silane coupling agent into the clarified solution obtained in step 2), and stir at a high speed until the mixture is evenly mixed, wherein the glass fiber is added in an amount of 1 to 30% of the mass of the c...

Embodiment 1

[0034] 1) Add 1470g of styrene, 30g of divinylbenzene and 500g of polystyrene powder into the container, stir at high speed until the solution is clear and transparent.

[0035] 2) Take 400g of chopped glass fiber with a length of 12mm and pour it into the γ-(methacryloyloxy)propyltrimethoxysilane (MPS) solution, soak it for 1 hour, take it out, rinse it with deionized water until it is neutral, and dry it. Dry.

[0036] 3) Add the chopped glass fiber treated with silane coupling agent into the above clear liquid, stir until it is evenly mixed, pour it into a special mold that can isolate water and oxygen, and seal it.

[0037] 4) Under the temperature of 5°C, 20kGy of gamma rays are irradiated to the mold containing the sample, and the radiation dose rate is 40Gy / min.

[0038] 5) Open the mold and take out the fully cured glass fiber reinforced cross-linked polystyrene board, and machine it until the shape is regular and the surface is smooth.

[0039] 6) Put the processed ...

Embodiment 2

[0043] 1) Add 950g of styrene, 50g of divinylbenzene and 500g of polystyrene powder into the container, stir at high speed until the solution is clear and transparent.

[0044] 2) Take 150g of chopped glass fiber with a length of 30mm and pour it into γ-(methacryloyloxy)propyltrimethoxysilane (MPS) solution, soak it for 1 hour, take it out, rinse it with deionized water until it is neutral, and dry it Dry.

[0045] 3) Add the chopped glass fiber treated with silane coupling agent into the above clear liquid, stir until it is evenly mixed, pour it into a special mold that can isolate water and oxygen, and seal it.

[0046] 4) Perform 30kGy gamma-ray radiation on the mold containing the sample at a temperature of 0°C, and the radiation dose rate is 20Gy / min.

[0047] 5) Open the mold and take out the fully cured glass fiber reinforced cross-linked polystyrene board, and machine it until the shape is regular and the surface is smooth.

[0048] 6) Put the processed glass fiber r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com