Automated Rod Cassettes for Deviated Well Drilling Rigs

A drill pipe box and drilling rig technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of low degree of automation, slow moving and transportation, inconvenient access, etc., to reduce labor intensity, high degree of automation, The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

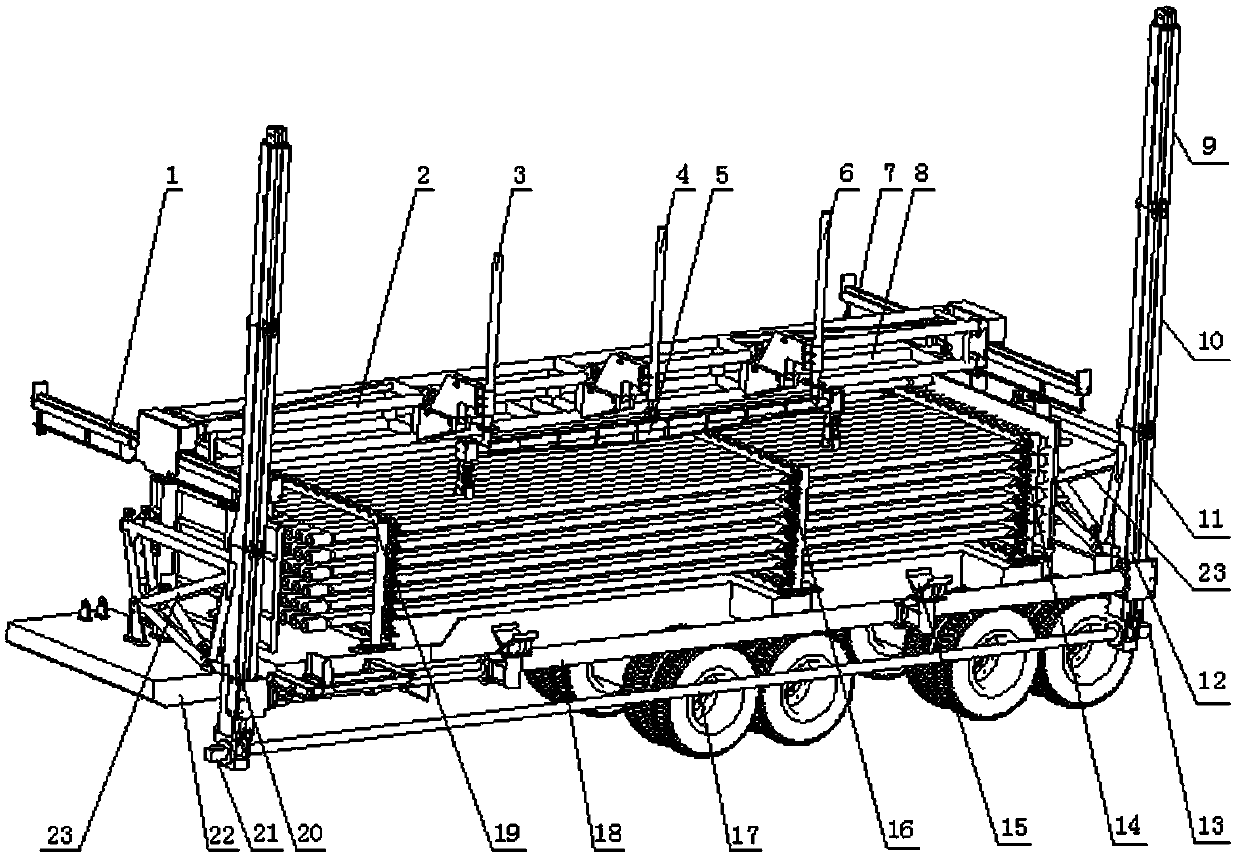

[0011] The structure of the automatic drill pipe box for the deviated well drilling rig of the present invention will be described in detail below in conjunction with the accompanying drawings.

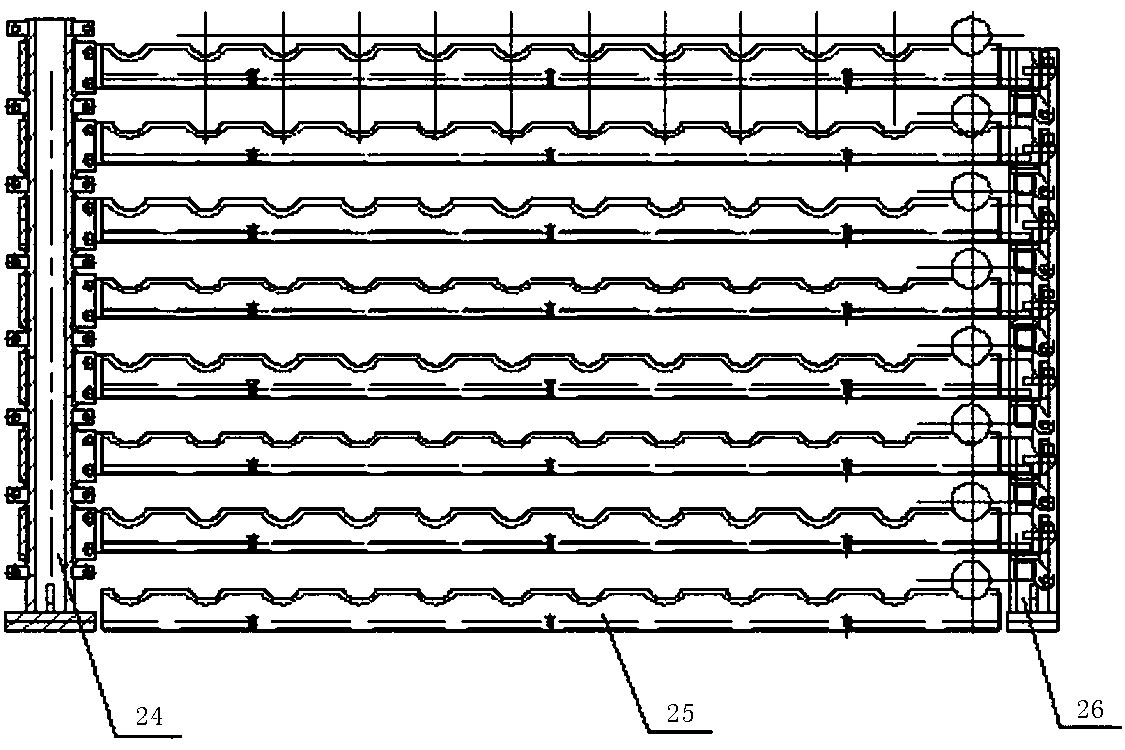

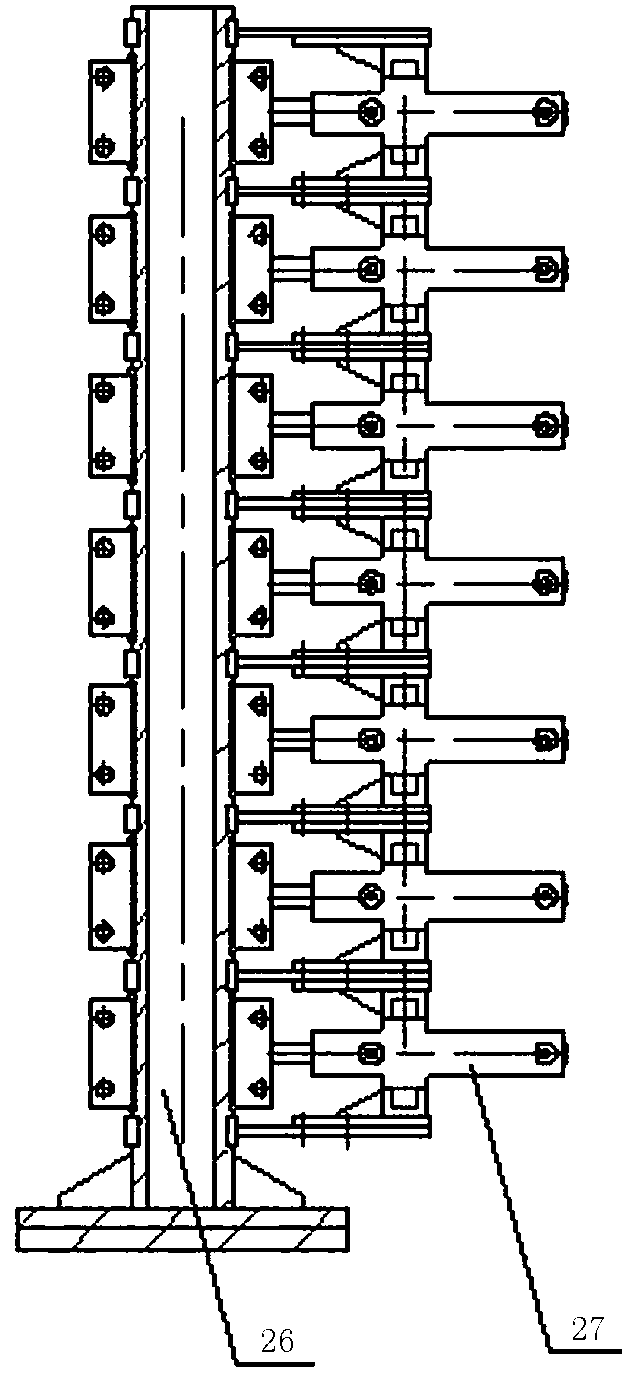

[0012] see Figure 1 to Figure 4 , the present invention is a kind of automatic drilling rod box that is used for inclined well drilling rig, and its structure comprises trailer 22, guide rail 1, 7 is set respectively at the front and rear ends of trailer 22, between guide rail 1 and guide rail 7 on trailer 22 Establish three drill pipe storage racks 19,16,14, see figure 2 , the two columns 24,26 of the drill pipe storage racks 19,16,14 are provided with a multi-layer drill pipe placement frame 25. see image 3 On the column 26 of the drilling rod storage rack 19,16,14, a hydraulic cylinder 27 is set at each layer of the drilling rod placement frame. The purpose of the hydraulic cylinder 27 is to drive the drilling rod placement frame to rotate around the column. On the two guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com