Chain wheel for power transmission system

A power transmission system, sprocket technology, applied in the direction of belt/chain/gear, transportation and packaging, components with teeth, etc., can solve problems such as low efficiency, troublesome replacement, unreasonable design structure, etc., and achieve convenient power transmission , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

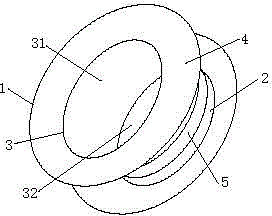

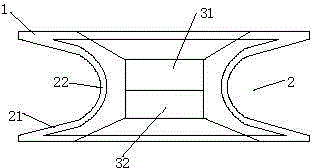

[0009] Combine below figure 1 and figure 2 Specific description embodiment:

[0010] like figure 1 and figure 2 As shown, the sprocket used in the power transmission system, the sprocket used in the power transmission system includes a wheel body 1, the side of the wheel body 1 is provided with an annular groove structure 2, and the annular groove structure 2 is composed of a tapered groove 21 and an arc groove 22, the taper of the tapered groove 21 is 30 degrees, the tapered groove 21 gradually shrinks toward the arc groove 22, and the arc groove 22 is located at the wheel The inner part of the body 1, the distance between the center of the bottom of the arc-shaped groove 22 and the center of the wheel body 1 is 50mm; the axial direction of the wheel body 1 is provided with a through-hole structure 3, and the through-hole structure 3 The hole structure 3 includes an upper hole 31 and a lower hole 32, the transition between the upper hole 32 and the upper end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com