A high-fidelity and high-purity flue gas sampling system applied to an indirect measurement device for high-temperature flue gas temperature

A measuring device and high-temperature flue gas technology, applied in measuring devices, thermometers, measuring heat, etc., can solve problems such as no methods and devices, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

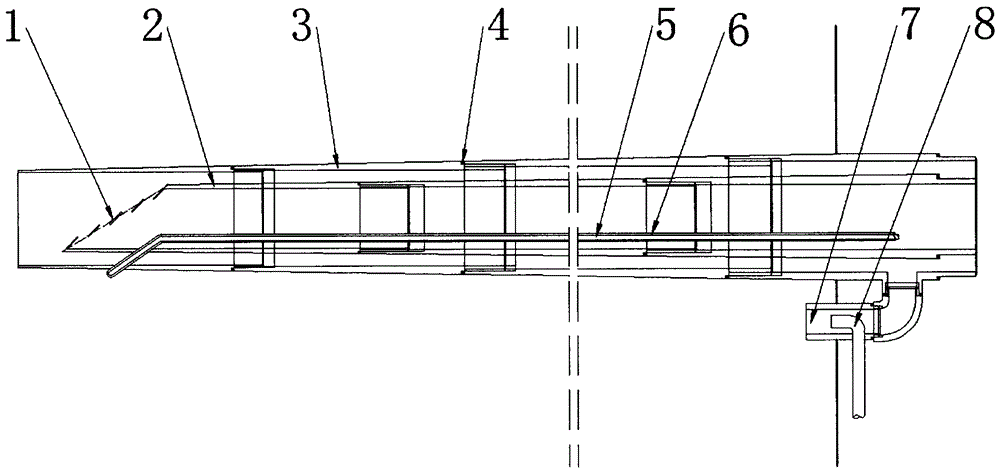

[0016] Now, a high-fidelity and high-purity flue gas sampling system applied to the high-temperature flue gas temperature indirect measurement device of the present patent will be further described with reference to the accompanying drawings.

[0017] The variable-length flue gas sampling pipe 2 is placed inside the double-layer heat-shielding sleeve 3, which is composed of multi-sections of high-temperature-resistant lightweight ceramic pipe sections threaded and sealed with high-temperature-resistant metal gaskets 4; the outer double-layer heat-shielding sleeve 3 is made of material And the connection method is the same as that of the flue gas sampling pipe 2; the shutter separator 1 placed at the front end of the flue gas sampling pipe 2 is used to separate out the solid dust particles in the flue gas in the furnace; the flue gas rich in dust particles passes through the double-layer heat shield The annular pipeline formed by the casing 3 and the flue gas sampling pipe 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com