Grid special for power battery

A power battery and grid technology, which is applied in the field of special grids for power batteries, can solve the problems of reducing the ability of the grid to carry active materials, the reactive area of active materials, and the poor strength of active materials on the plates, so as to achieve enhanced bonding and extreme The effect of increasing the strength of the plate active material, improving the electrical conductivity, and optimizing the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

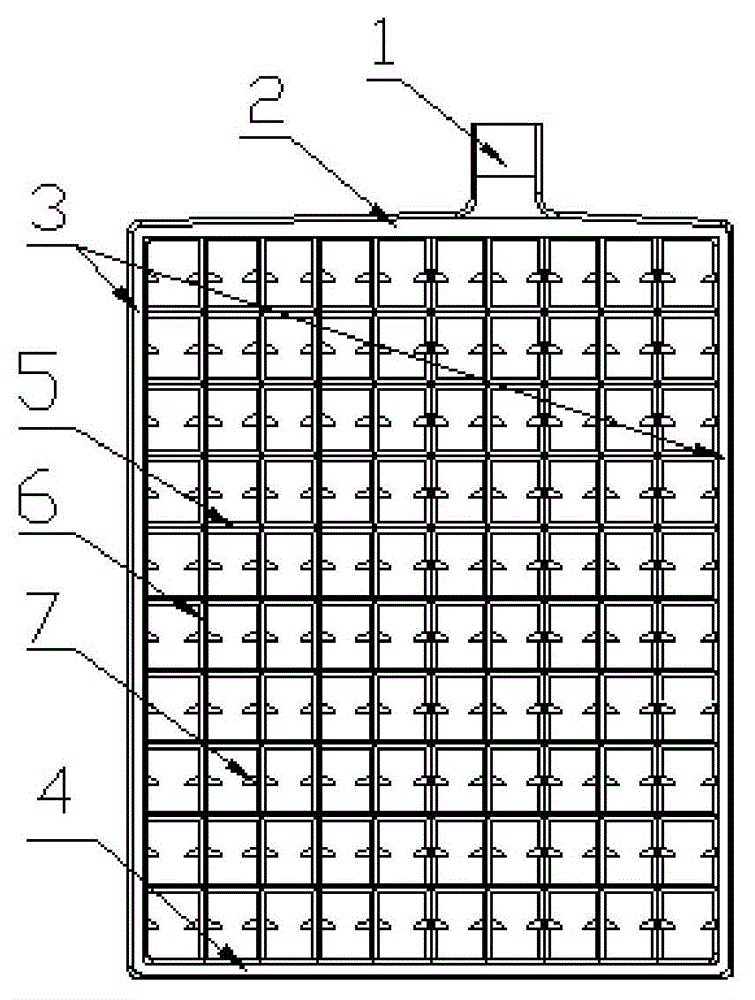

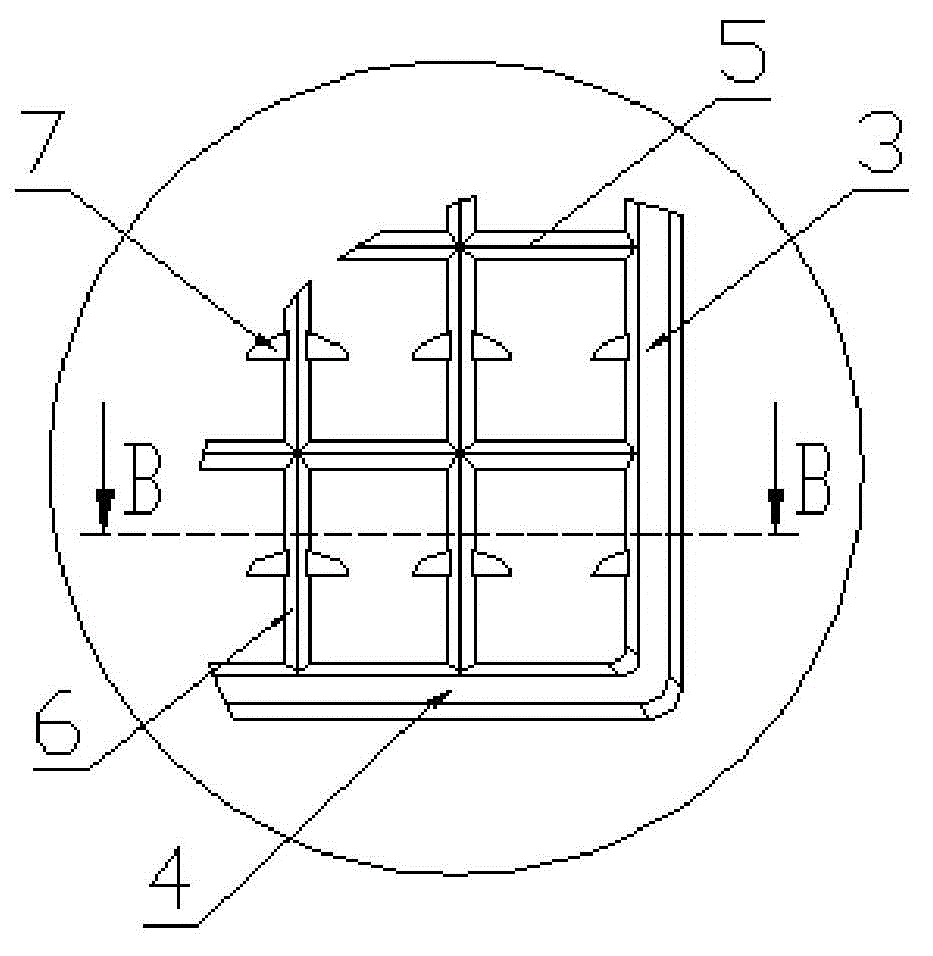

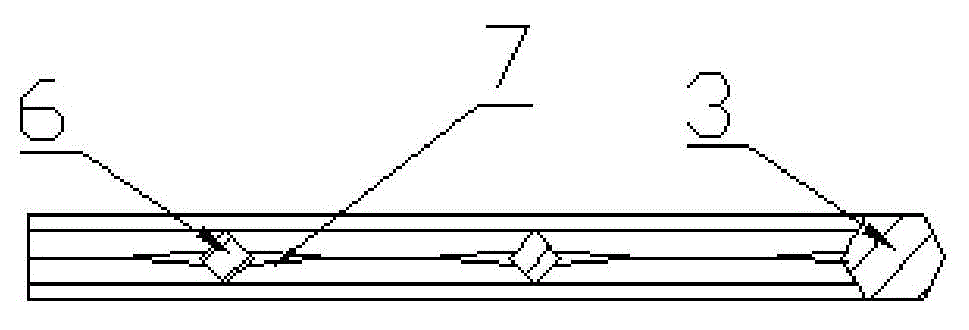

[0021] The following combination Figure 1 to Figure 3 The embodiment of the grid dedicated to the power battery of the present invention is described in detail.

[0022] Such as figure 1 and figure 2 As shown, a special grid for a power battery includes a grid body, a frame is arranged around the grid body, and the middle part of the upper frame 2 is connected with a tab 1, and the grid body is provided with transverse ribs on the inner side of the frame. 5 and a rib grid formed by vertical ribs 6, said vertical ribs 6 are vertically provided with several side wings 7 protruding to both sides, and the upper contour of said side wings 7 is inclined to the downward side (with the vertical rib The slope of the strips works best between 30° and 60°). Adding side wings 7 protruding to both sides on the vertical ribs 6 can enhance the bonding force between the grid and the active material and ensure the strength of the active material of the pole plate, and the purpose of makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com