Detection method of contamination of image pickup module and detection system

A camera module and detection method technology, applied in image communication, television, electrical components and other directions, can solve problems such as difficult to see, reduce production efficiency, reduce detection speed, etc., achieve convenient and direct observation, improve production efficiency, improve Detecting the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

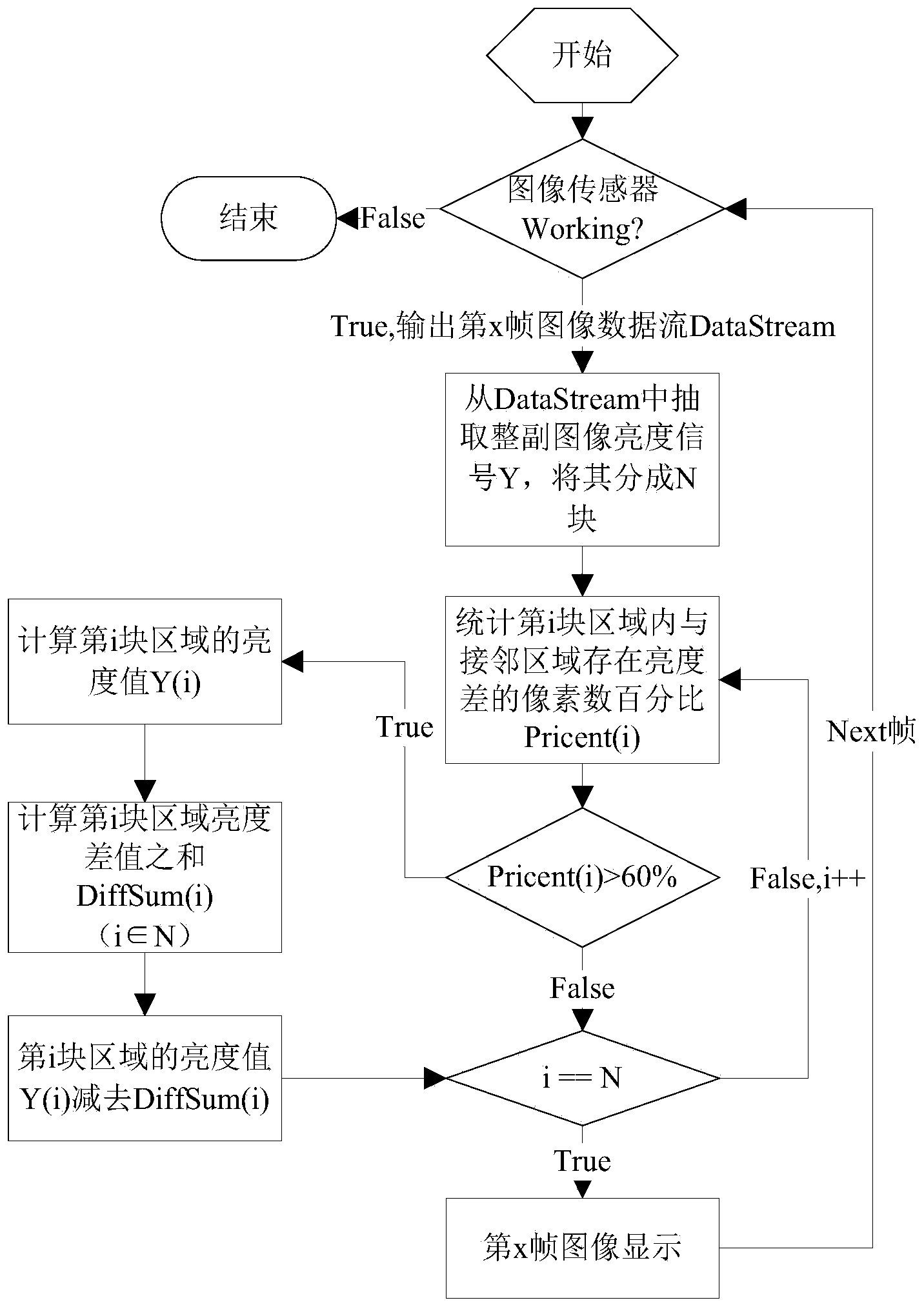

[0032] Example: see figure 1 , the present embodiment provides a camera module dirty detection method, which includes the following steps:

[0033] (1) A test background and an image processing module are set, and the pixel point percentage value is preset in the image processing module;

[0034] (2) prepare the camera module to be tested, and obtain the image data of the test background described in step (1) by the camera module to be tested;

[0035] (3) the image processing module extracts the brightness signal of the whole image from the image data obtained in step (2), and divides it into N block regions;

[0036] (4) Determine whether the number of pixels with a brightness difference from the adjacent area in the i (i∈N) block area accounts for the percentage of the number of pixels in the area, whether it is greater than the preset dirty judgment pixel percentage value in step (1) ;

[0037] (5) If in this area, the percentage of the number of pixels with brightness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com