Kneading system with sealed rubber kneading machine

A kind of rubber mixer, closed technology, applied in the direction of mixers, mixers, mixer accessories, etc. with rotary mixing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

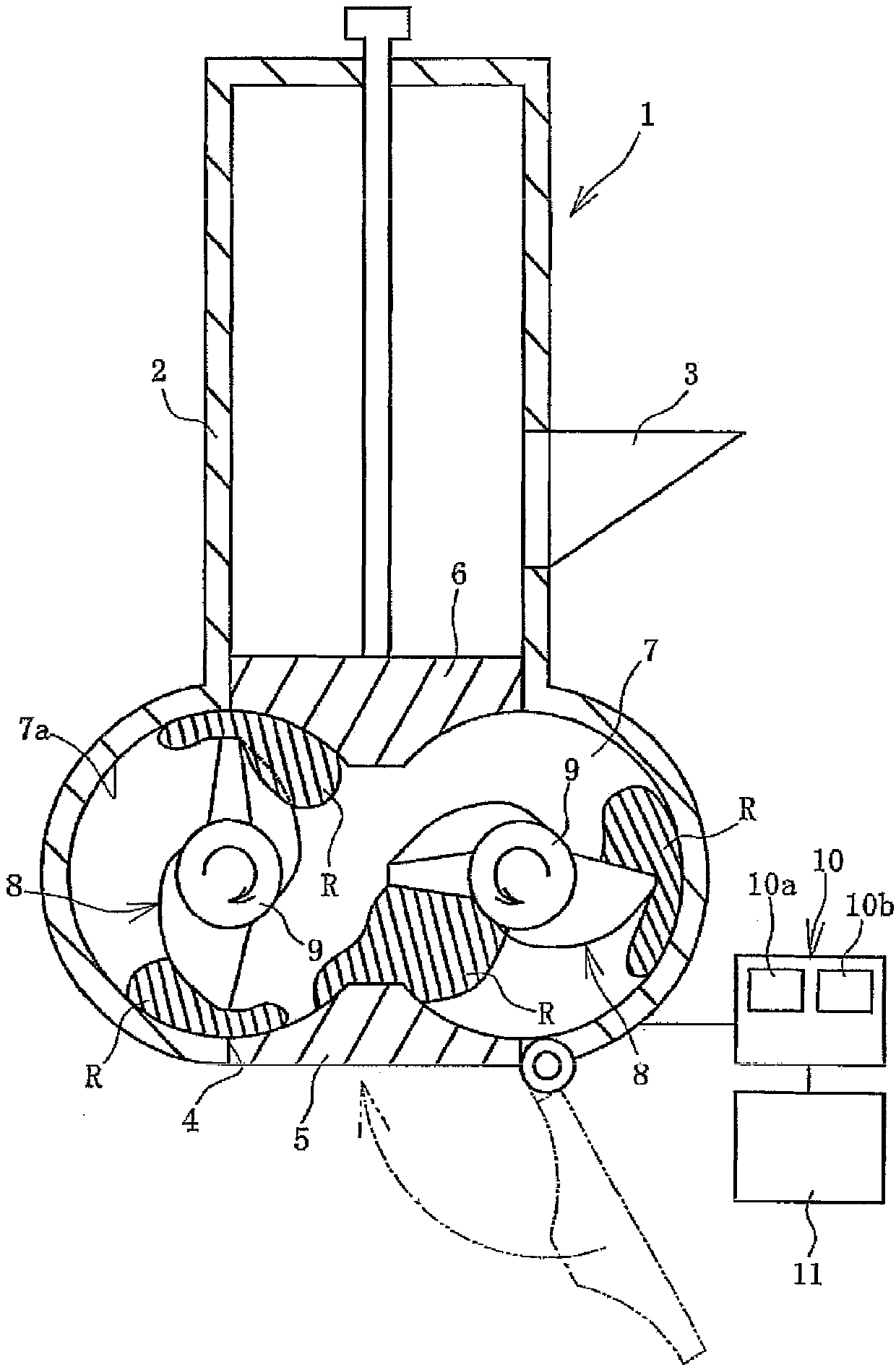

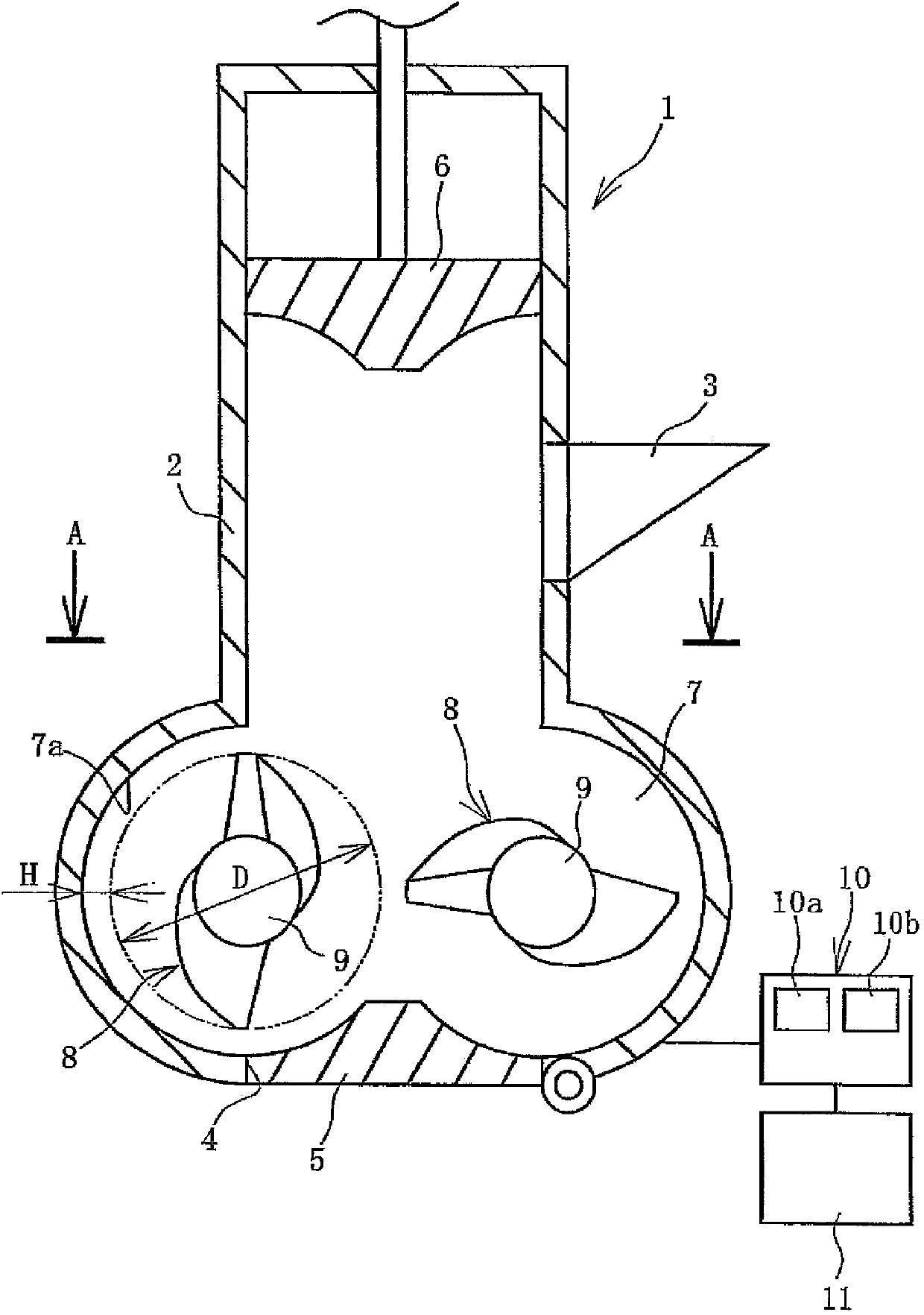

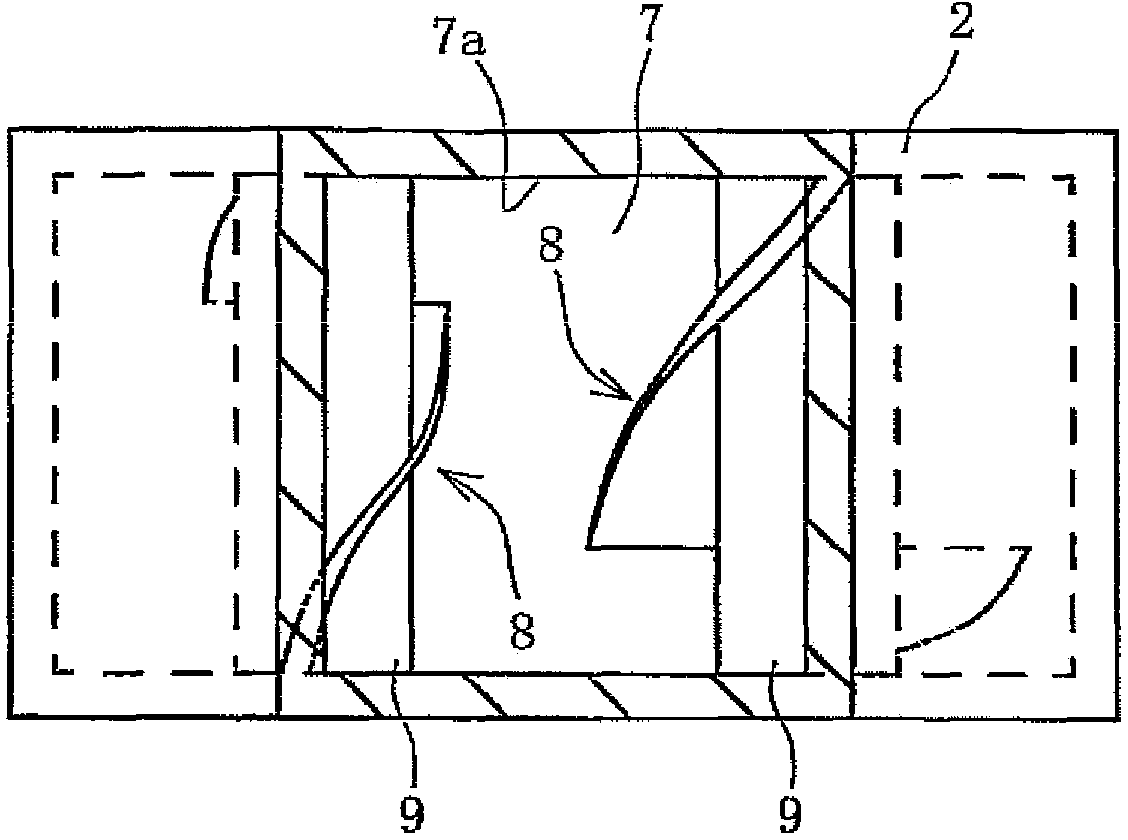

[0025] Hereinafter, a kneading system including a closed rubber kneader according to the present invention will be described based on embodiments shown in the drawings.

[0026] Such as Figure 1 ~ Figure 3 As shown, the mixing system of the present invention has: a closed rubber mixer 1 (hereinafter referred to as the mixer 1), which mixes the mixing material R containing raw rubber and carbon black; a tachometer 10a, which detects The rotational speed N of the rotor 8 of the kneader 1; the power meter 10b, which detects the instantaneous power p required to rotationally drive the rotor 8; and the computing device 11, into which the detection data of the tachometer 10a and the power meter 10b are input.

[0027] The tachometer 10 a and the power meter 10 b are provided on a rotor drive unit 10 that rotationally drives the rotor shaft 9 . For the rotor drive unit 10, for example, a drive motor or the like can be used.

[0028] The kneader 1 has a material inlet 3 midway up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com