A kind of solid base catalyst and its preparation and application in the preparation of guaiacol glyceryl ether

A solid base catalyst, glycerol technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of adverse effects on the environment and human body, high boiling point of solvent DMF, and many steps, and achieves low energy consumption, Easy to operate, environmentally friendly and easy to regenerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

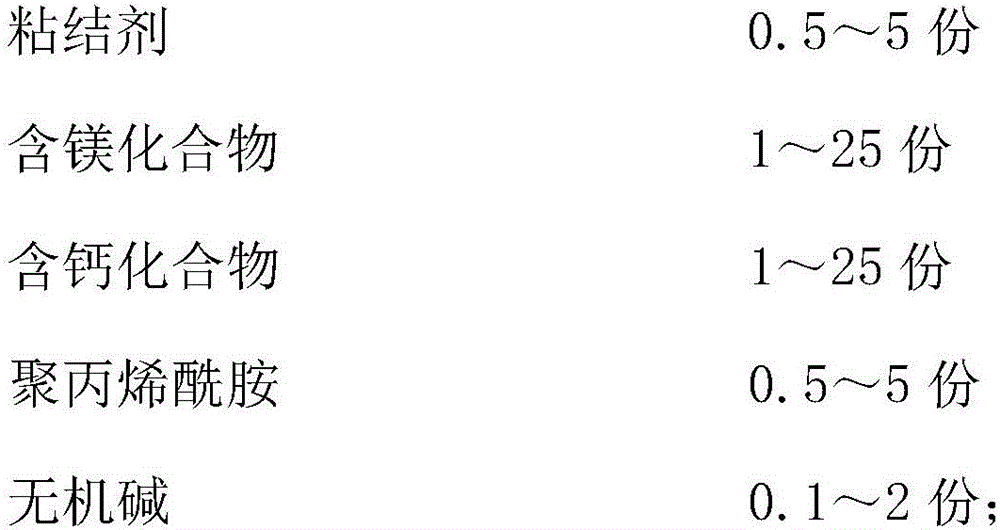

Method used

Image

Examples

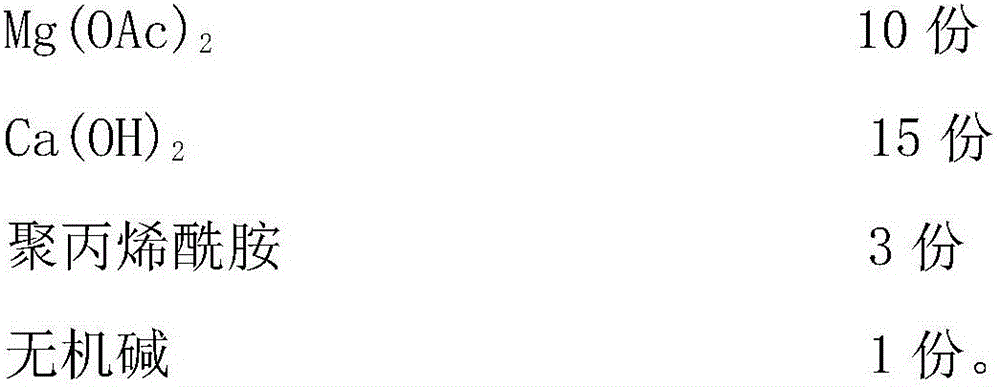

Embodiment 1

[0035] Take 100g γ-Al 2 o 3 (Wenzhou Jingjing Alumina Co., Ltd.), add 2g aluminum sol (Jiangyin Xiagang Chemical Factory) as a binder, add 15gMg(OAc) 2 , mix and grind for 1 hour, add 10g Ca(OH) 2 , add 1g NaOH, add 3g polyacrylamide (Henan Luoshan Zhongyuan Polymer Co., Ltd., molecular weight 8 million to 10 million) as an extrusion aid, continue mixing and grinding for 2 hours, add 20g of water, and extrude it into mm strips. Dry the product under infrared light for 5 hours, put it in an oven to dry at 100°C for 10 hours, and finally put it in a muffle furnace and bake it at 500°C for 4 hours to obtain a composite solid alkali catalyst. After cooling, put it in a desiccator for use.

Embodiment 2

[0037] Take 100g γ-Al 2 o 3 As a carrier, add 3g glycerin as a binder, add 15gMgO, mix and grind for 1 hour, add 10gCa(OH) 2 , add 1gKOH, add 5g polyacrylamide (Henan Luoshan Zhongyuan Polymer Co., Ltd., molecular weight 8 million to 10 million) as an extrusion aid, continue mixing and grinding for 2 hours, add an appropriate amount of water, and extrude it into mm strips. Dry the product under an infrared lamp for 1 hour, put it in an oven for 8 hours at 120°C, and finally place it in a muffle furnace for calcination at 550°C for 4 hours to obtain the composite solid alkali catalyst. After cooling, place it in a desiccator for use.

Embodiment 3

[0039] Take 100g γ-Al 2 o 3 , add 3g starch as binder, add 10gMgCO 3 , mix and grind for 0.5 hours, add 10g Ca(OH) 2 , add 0.5gNa 2 CO 3 , add 2g polyacrylamide (Henan Luoshan Zhongyuan Polymer Co., Ltd., molecular weight 8 million to 10 million) as extrusion aid, continue to mix and grind for 2 hours, add an appropriate amount of water, and extrude it into mm strips. The product was dried under an infrared lamp for 5 hours, placed in an oven for 6 hours at 100°C, and finally placed in a muffle furnace for 3 hours at 500°C to roast to obtain the compounded solid alkali catalyst, which was cooled and placed in a desiccator for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com