Ink controlling scheme for printing presses having short inking units

A technology of printing presses and regulators, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., can solve the problems of reducing printing speed, changing the production speed of printing machines, and unfavorable rapid production, etc., to achieve adjustment and regulation loops Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

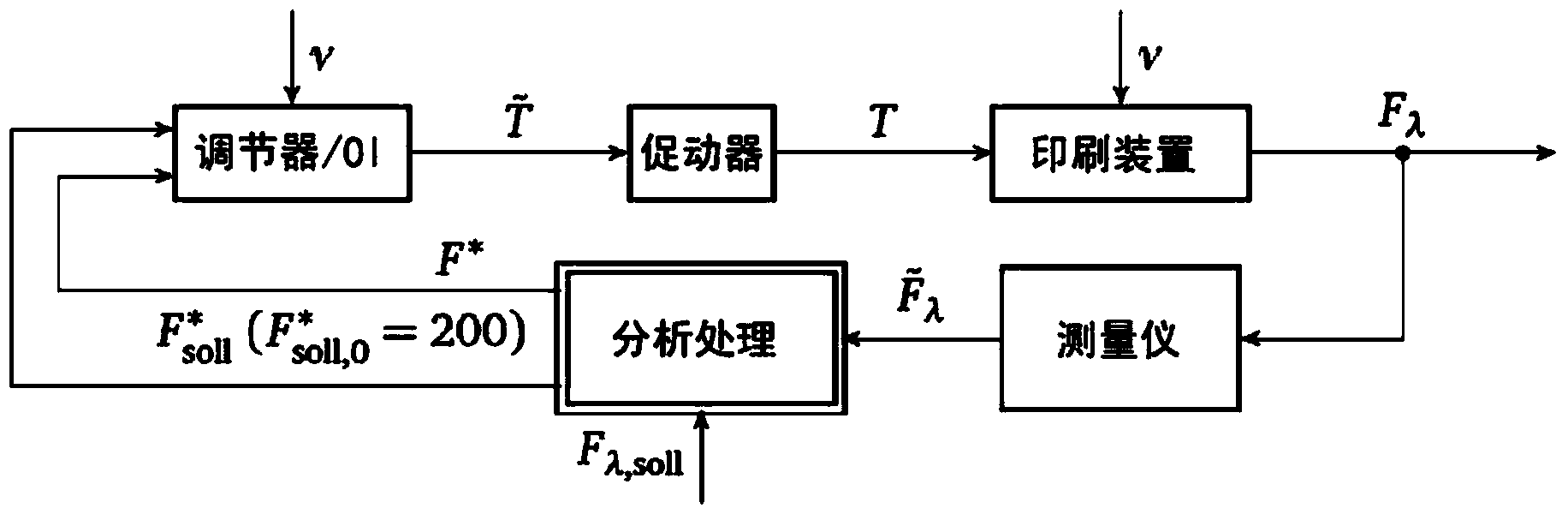

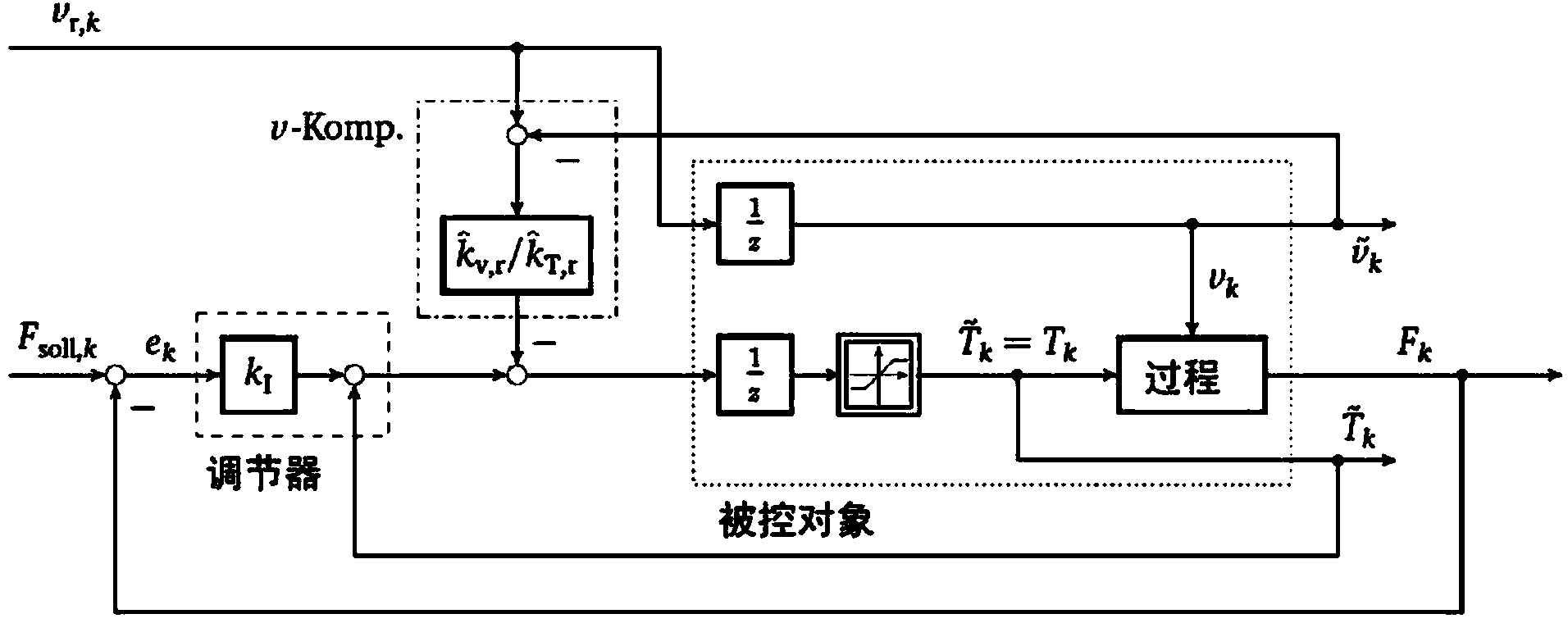

[0026] exist figure 1 The structure of the regulation circuit for the ink regulation of an offset printing press with a short inking unit is shown in . Here, the actual coloring (or inking) is measured with the aid of a color meter The actual coloring is superimposed by the control means. measured actual coloration is analyzed in the control computer of the printing press and compared with the rated coloring F λ,sollCompared. exist figure 1 Medium, color density F soll The rated value of 200 is predetermined. If the analysis process indicates that the color actual value F * With a value of 220, the color measuring device determines a 10% higher color density on the tested printing material. This difference must now be adjusted via a regulator. Furthermore, the controller has the printing speed v of the printing press as an input variable, wherein the controller calculates and predetermines a temperature T superimposed by a control device using the set printing speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com