Cable break prevention device for cable vehicle and using method thereof

An anti-breakage and cable technology, which is applied in the direction of vehicle components, transportation and packaging, circuits or fluid pipelines, etc., can solve the problems that the shaft and cable steel pipes are not suitable, difficult to replace, and large economic losses, etc., to reduce the axial and Circumferential fatigue damage, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

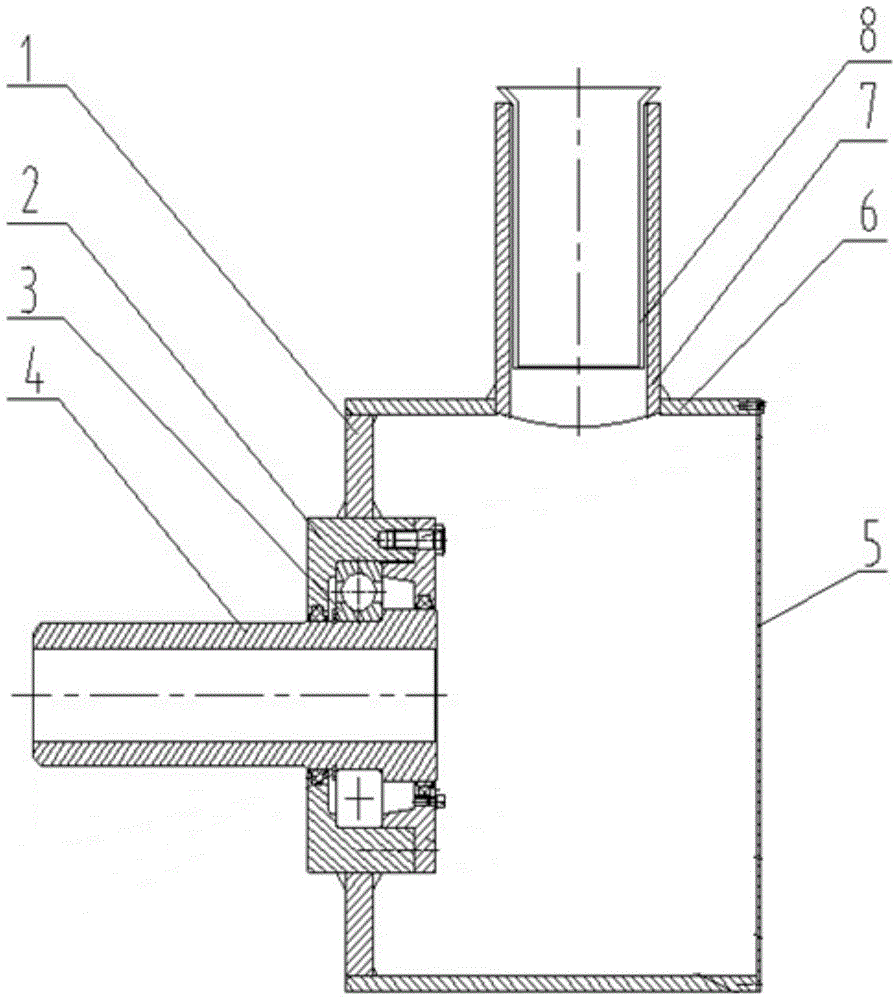

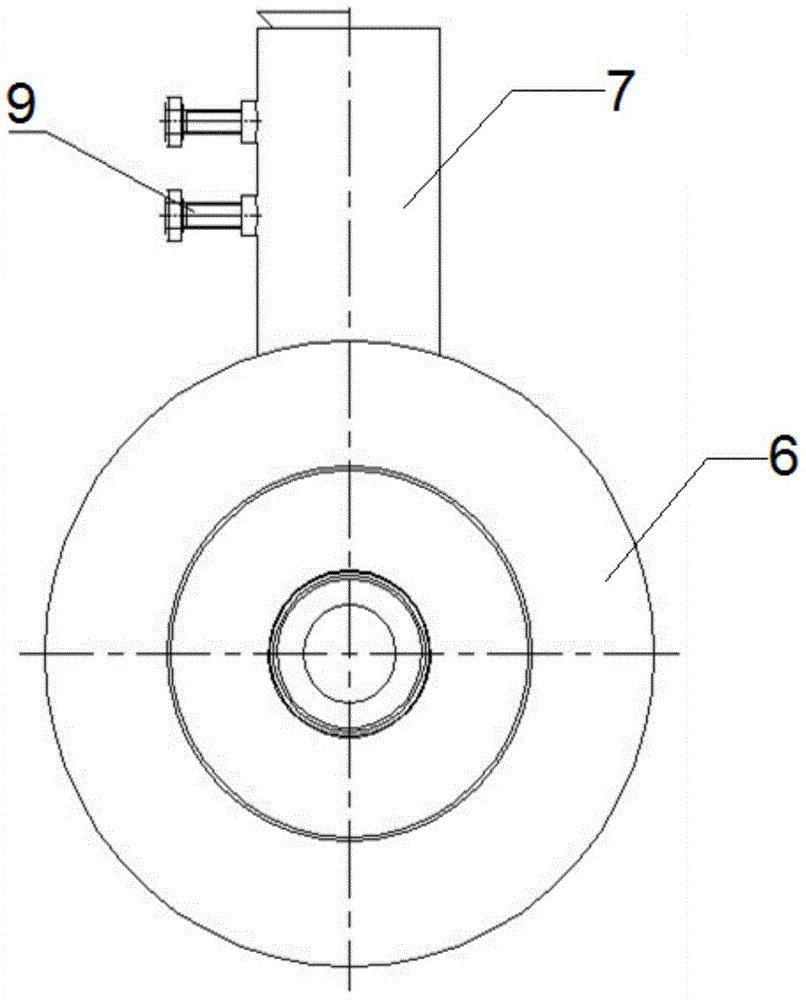

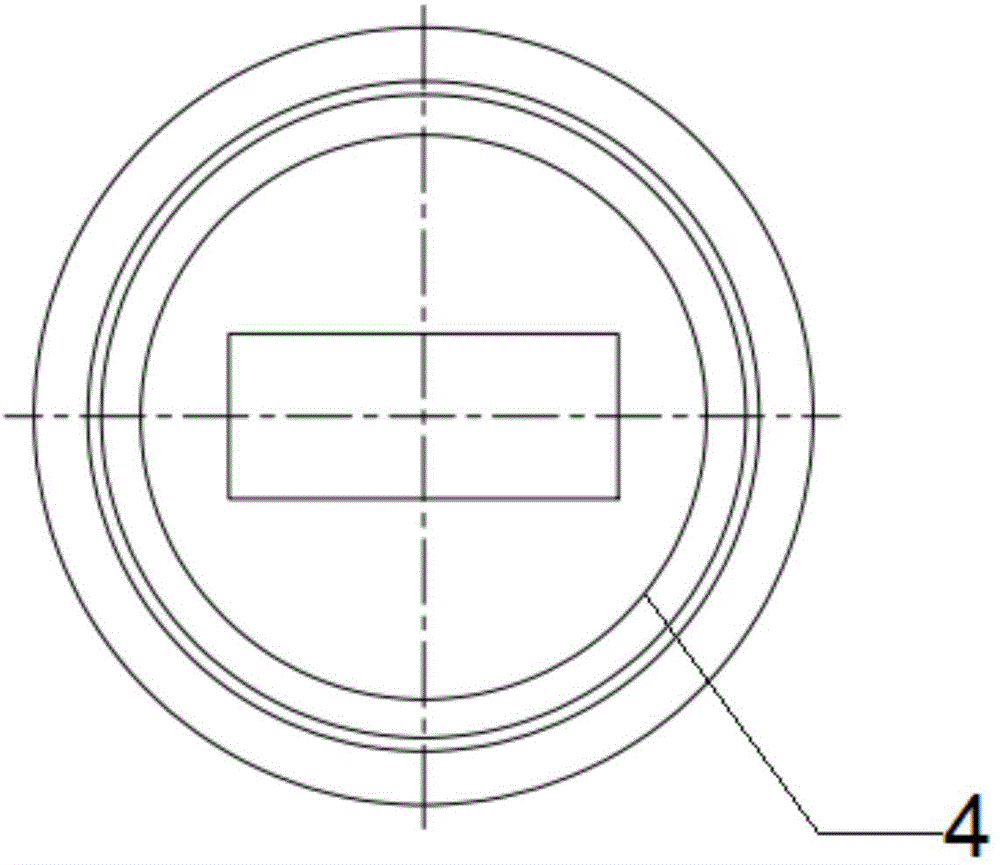

[0034] see figure 1 , a cable breakage prevention device for a cable vehicle, including a cylinder 6 that can accommodate cables, a support plate 1 is provided at one end of the cylinder 6, a bearing seat 2 is provided on the support plate 1, and a bearing 3 is installed in the bearing seat 2 , also includes the shaft 4 that cooperates with the bearing 3, such as image 3 As shown, the shaft 4 is provided with a channel communicating with the cylinder 6;

[0035] The side of the cylinder 6 is also provided with a cable steel pipe 7 communicating with the cylinder 6, the passage of the shaft 4, the cylinder 6 and the cable steel pipe 7 form a passage for cables to pass through.

[0036] The cable steel pipe 7 is provided with a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com