Method for producing elastic spacer fabric through two-needle bar warp knitting machine

A spacer fabric and elastic technology, applied in the field of fabric textiles, can solve the problems of insufficient compactness, complexity, rough fabric style, etc., and achieve the effect of good elasticity and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0029] Unless expressly stated otherwise, throughout the specification and claims, the term "comprising" or its conjugations such as "comprising" or "comprising" and the like will be understood to include the stated elements or components, and Other elements or other components are not excluded.

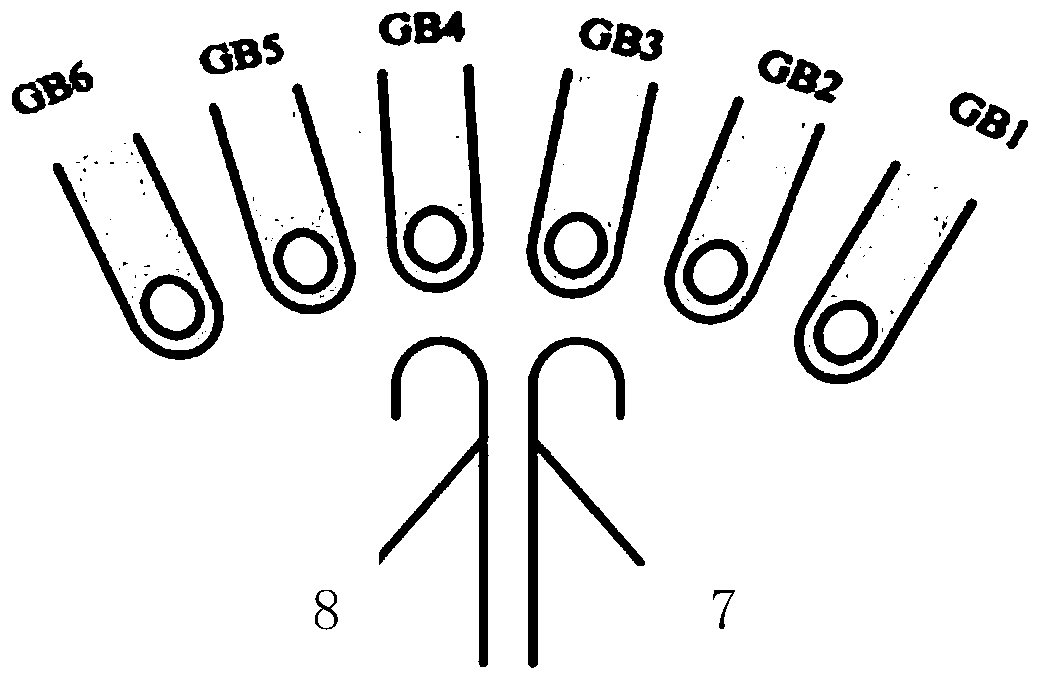

[0030] like figure 1 Shown, according to a kind of 6-comb double-needle-bed warp knitting machine according to the specific embodiment of the present invention produces the method for shoe material, and its steps are:

[0031] (1) Bar configuration: GB1 and GB6 are elastic bars, GB2, GB3, GB5 are ground bars, and GB4 is spacer yarn guide bar;

[0032] (2) Configure the distance: the spacer fabric is used for the shoe material fabric, and the distance between the front need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com