A method for prolonging the service life of the air door of the secondary air cooler

A cooling fan and damper technology, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problems of insufficient closing of dampers, low connection strength between damper blades and damper rotating shaft, and damper blades. Insufficient welding strength and other problems, to avoid insufficient welding strength and improve the effect of welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

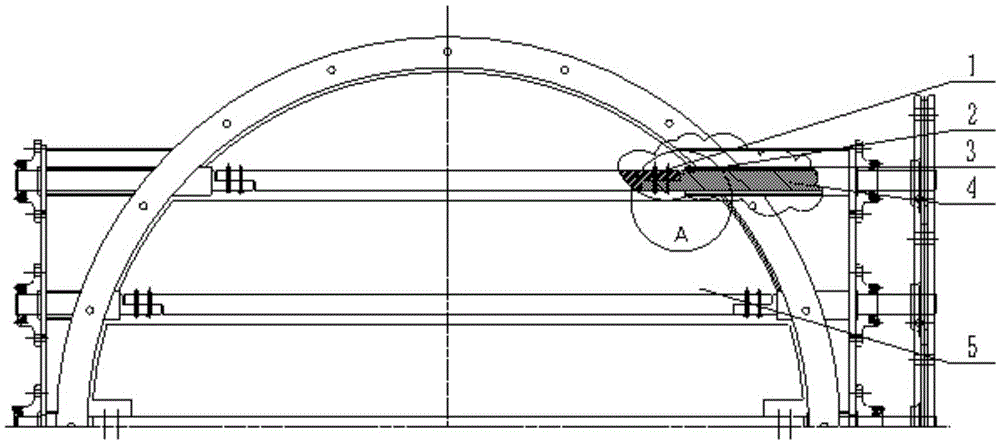

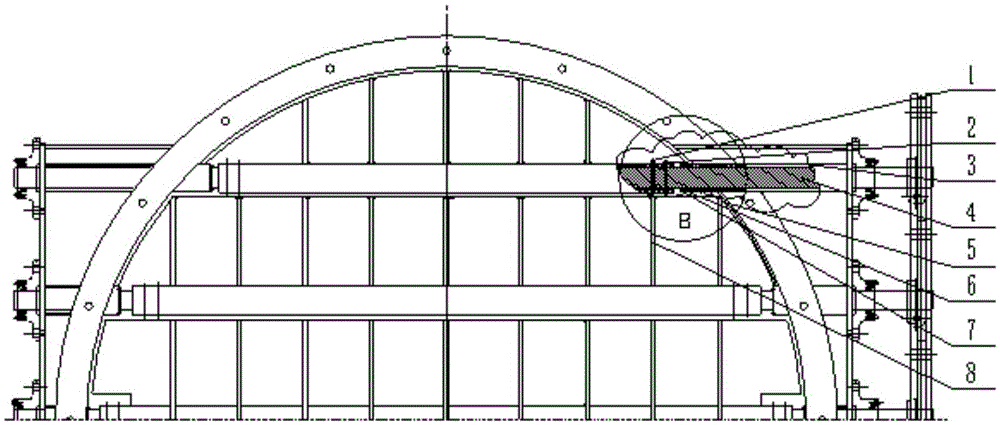

Image

Examples

Embodiment 1

[0021] 1. According to the size of the existing fan blades, make 3 types of blade reinforcement ribs. The material is 0Cr18Ni9 steel, and the thickness is 5mm. The dimensions are e1=15mm, n1=30mm, h1=128mm; e2=15mm, n2=40mm, h2=178mm; e3=15mm, h3=400mm, R1=31mm, R2=50mm. Weld and fix the manufactured blade stiffeners on the fan blades.

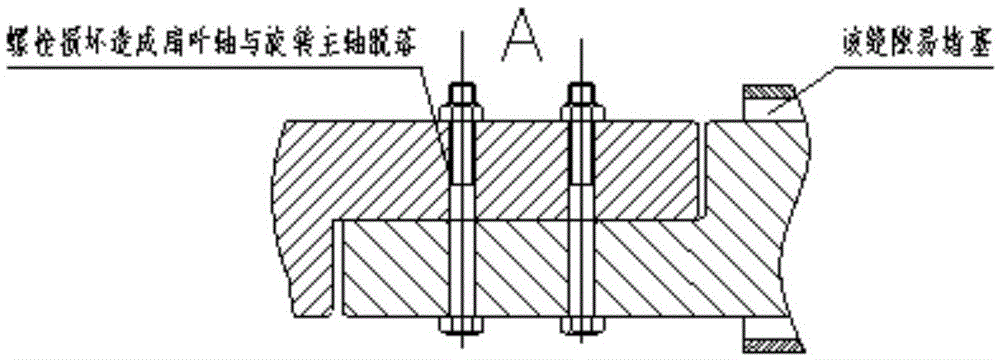

[0022] 2. According to the original spindle casing size d6=70mm, determine Figure 4 The processing dimensions of the main shaft casing packing seal groove in a = 10mm, d5 = 50mm, d4 = 45mm. The rotating spindle is processed into a shaft with a diameter of 40mm and a length of 1685mm, and quenching and tempering heat treatment is performed on the spindle. Connect the prepared fan blade shaft 2 with the rotating main shaft 4, and fasten it with the fastening bolt 1 in a limited position.

[0023] 3. Without changing the size of the original design of the spindle casing and the size of the rotating spindle, determine the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com