Generator with simultaneous cooling of multiple components

A generator, multi-component technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of decreased insulation of motor components, increased temperature of mufflers, and inability to cool, so as to improve cooling effect and reduce manufacturing. cost, the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

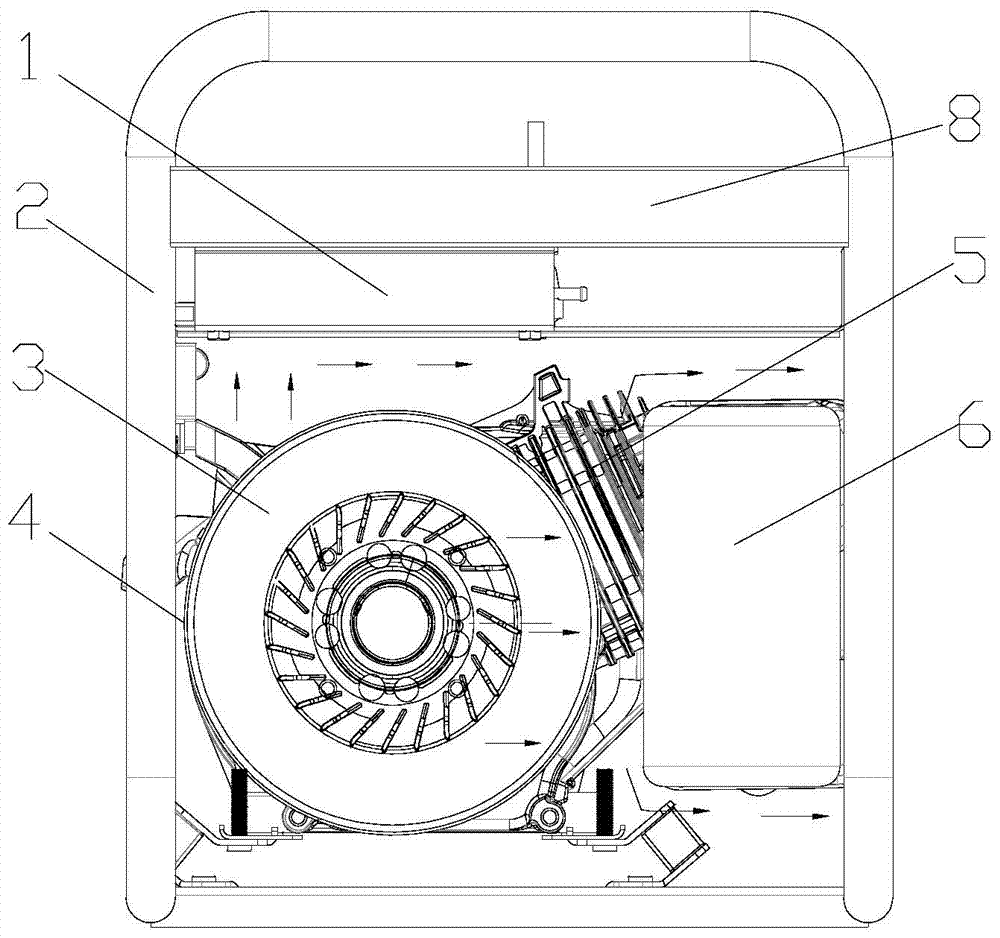

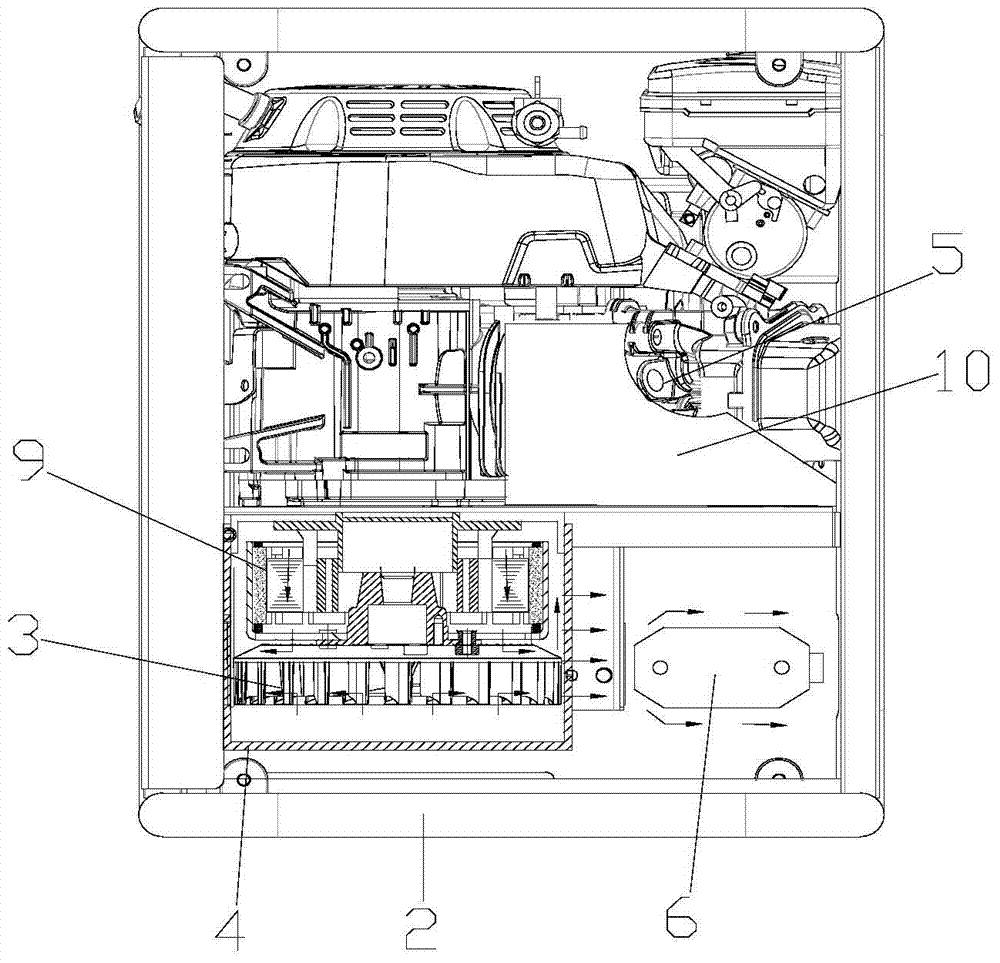

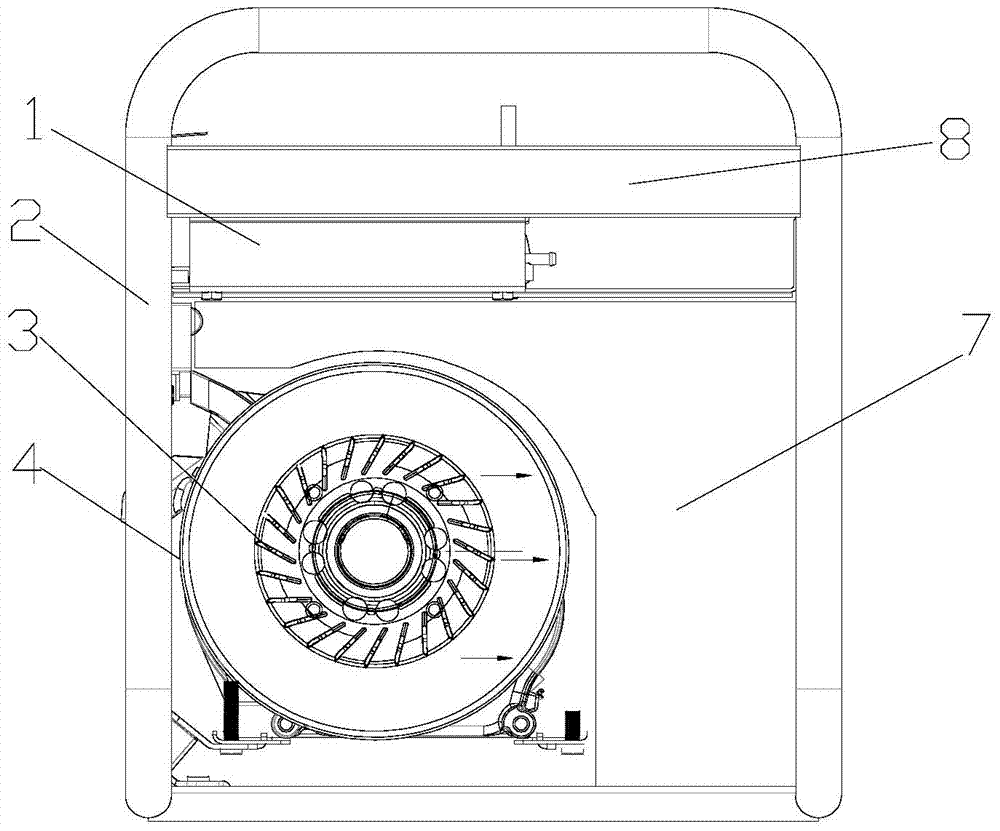

[0017] figure 1 It is the front view of the present invention, figure 2 It is a top view of the present invention, as shown in the figure, a multi-component simultaneous cooling generator provided by the present invention includes at least an engine 5, a motor assembly 9 connected to the engine 5, and a mounting bracket for installing the engine 5 and the motor assembly 9 The frame 2 is characterized in that it also includes a centrifugal fan 3, an inverter 1 and a muffler 6, the centrifugal fan 3 is arranged at the rear end of the motor assembly 9 and the motor assembly 9 is located between the fan 3 and the engine 5 And the air is formed to flow from the engine 5 to the centrifugal fan 3 and the double air-intake heat dissipation channel that flows in from the rear end of the centrifugal fan 3. The fan 3 is connected to the engine 5 in transmission, and the muffler 6 and the inverter 1 are provided. On the air outlet side of the centrifugal fan 3 and the muffler 6 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com