Method of making a flexible circuit

A technology of flexible circuits and flexible substrates, applied in printed circuits, printed circuits, manufacturing tools, etc., can solve problems such as inapplicable lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

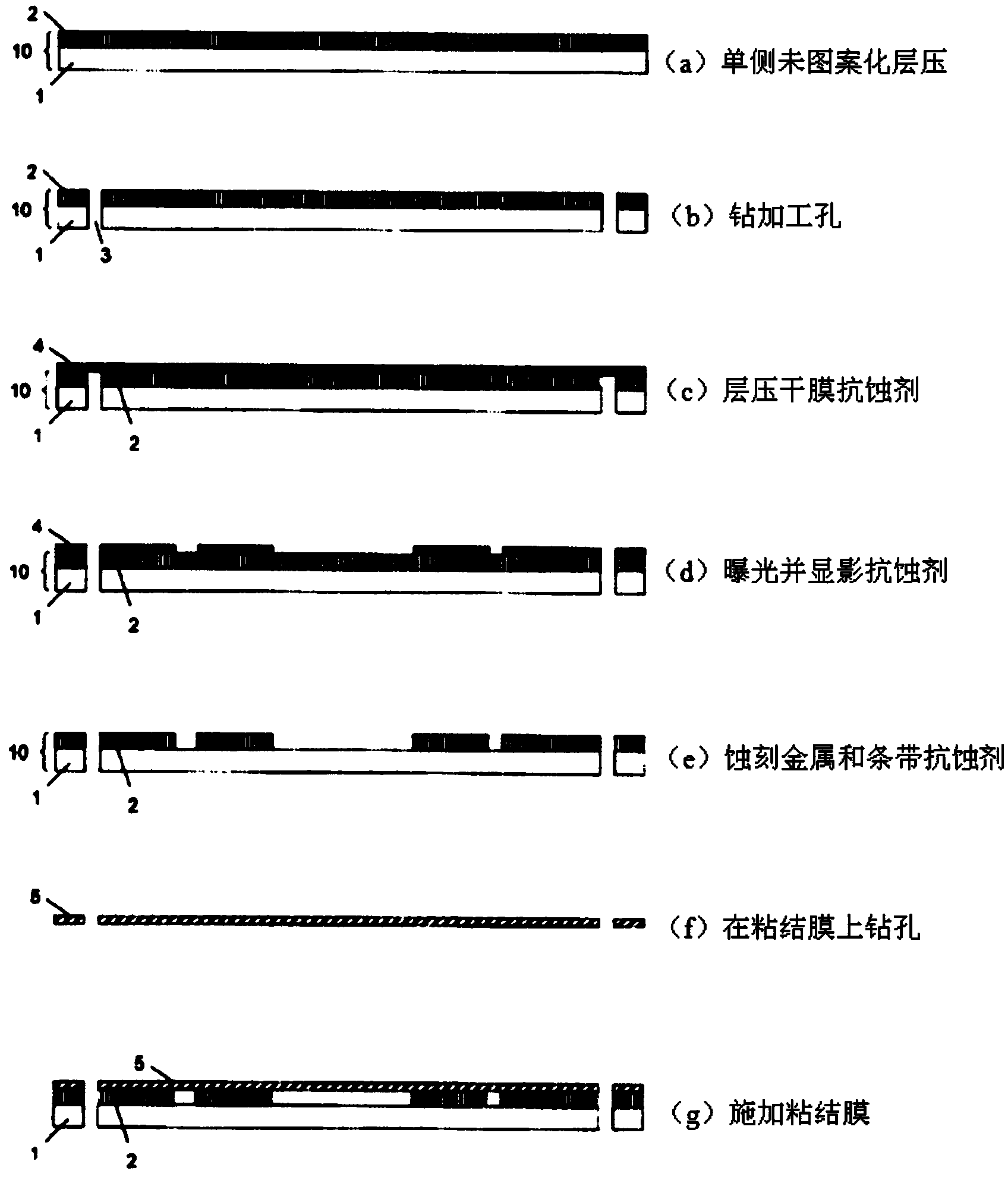

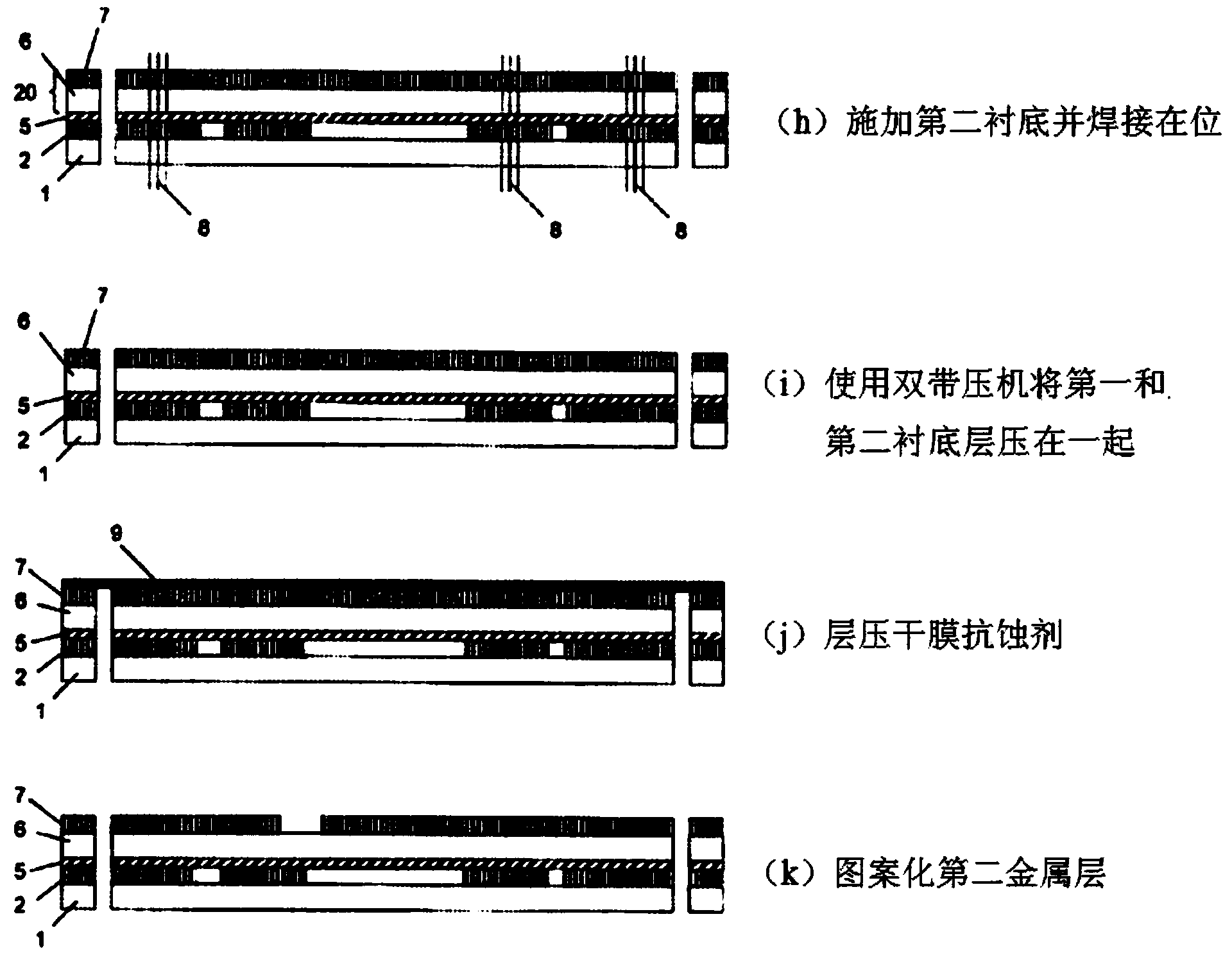

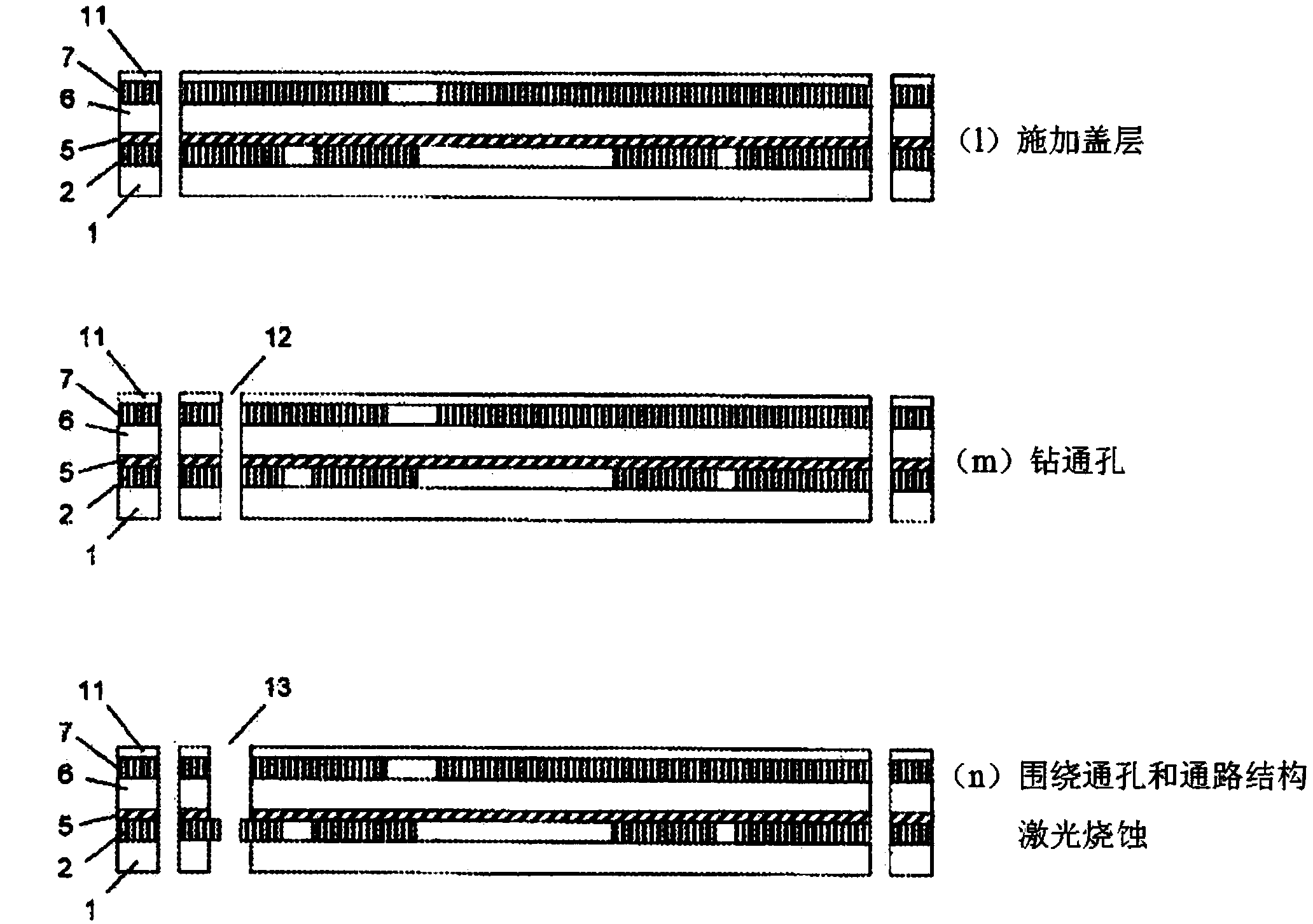

[0051] According to the first embodiment, the method for producing a multi-layer flexible PCB of any length is summarized as the following steps (a) to (k), hereinafter referred to Figure 1 to Figure 3 to describe.

[0052] It should be understood that, for simplicity, Figure 1 to Figure 8 The topology obtained by laminating the first and second substrates 10, 20 is not shown, but each layer is illustrated as a plane. For example, in practice the adhesive film 5 introduced below would be partially reflowed to partially planarize the topology of the patterned conductive layer, and the layer overlying the topology would bend to fit the topology; for simplicity, in It is not shown in the figure.

[0053] The method according to the first embodiment starts with (a) a first pre-lamination substrate 10 of suitable length comprising an unpatterned continuous metal conductive layer 2 on a continuous unpatterned insulator layer 1 . Such substrates 10 are well known to the skilled ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap