Series-parallel four-degree-of-freedom transferring and stacking robot

A technology of palletizing robots and degrees of freedom, which is applied in the field of palletizing machinery, can solve the problems of large force at the fulcrum of the lever, large driving force, and difficult wiring, and achieve the effect of stable movement and high handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

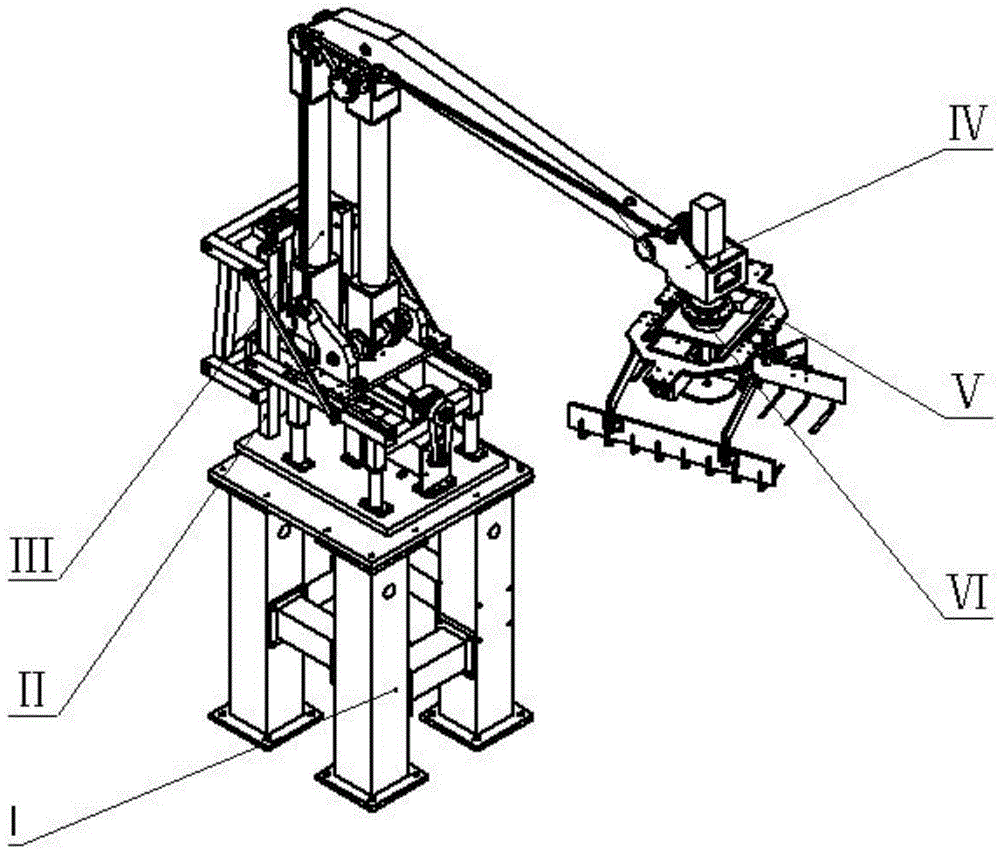

[0024] Such as figure 1 As shown, the series-parallel four-degree-of-freedom grain production line handling and palletizing robot of the present invention is composed of a bracket I, an arm mechanism II, a welding frame III, a wrist mechanism V, a hand grip VI and a wrist level holding mechanism IV, and adopts electric control and Driven by the pneumatic system, the waist of the robot can be rotated, the two-dimensional translation of the wrist in the plane formed by the big and small arms, and the hand can rotate around the wrist and grasp and press the bag.

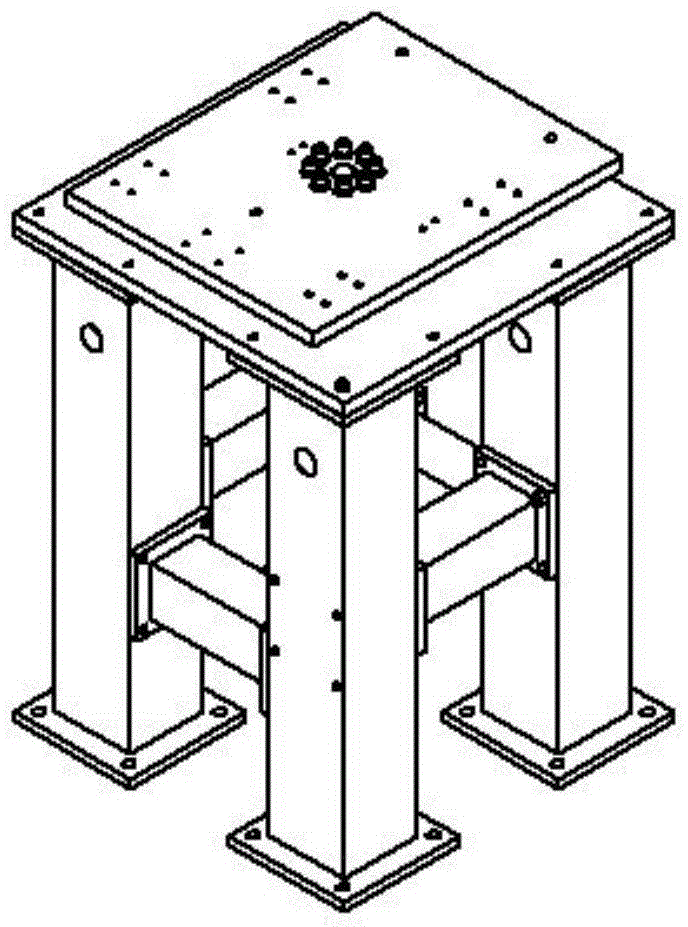

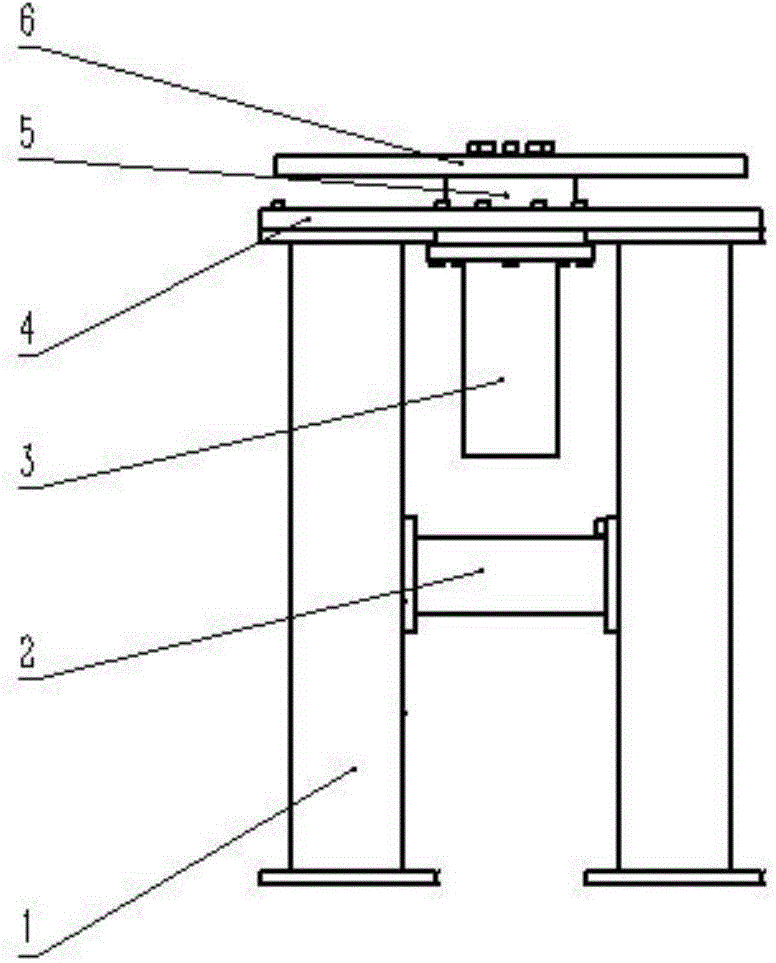

[0025] Such as figure 2 , 3 As shown, the support 1 includes a support leg 1, a support leg beam 2, a waist base plate 4, a rotating base plate 6, a waist servo motor 3 and a harmonic reducer 5; the waist base plate 4 is installed on the support leg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com