Light alloy type special wheel

A light alloy and special technology, applied in rims, vehicle parts, transportation and packaging, etc., can solve the problems of high cost, reduce energy loss, improve field survivability, and facilitate assembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

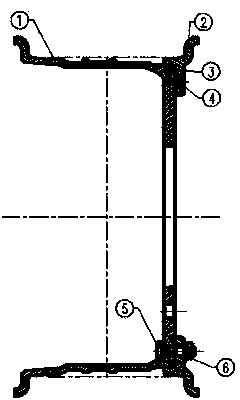

[0013] Such as Figure 1-4 As shown, the light alloy special wheel consists of light alloy inner rim body 1, light alloy outer rim body 2, "O" type rubber sealing ring 3, threaded valve 4, high-strength fine-thread bolts 5, and flanged fine-thread nuts 6 composition.

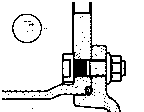

[0014] The high-strength fine-thread bolt 5 is provided with knurling 7, and is connected with the inner rim body by interference fit; this makes it easy to replace tires in special environments such as field and battlefield, and only use ordinary wrenches.

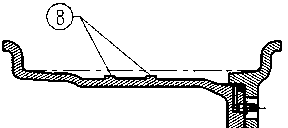

[0015] Inner rim body 1 is provided with supporting body annular boss 8, can install hard supporting body, and wheel can be used as the rim of run-flat tire like this; The tire 12 constitutes.

[0016] The present invention is provided with a built-in inflatable passage 9, which is threadedly connected to the air valve, and the built-in inflatable passage can avoid air leakage caused by stones hitting the air valve, which is safe and reliable; meanwhile, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com