Lower sealing structure for door

A sealing structure and sealing strip technology, applied in the field of auto parts, can solve the problems of high door closing force, high cost of decorative panels, inconvenience for passengers to get on and off the trouser legs, etc., and achieve the effect of preventing sediment accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

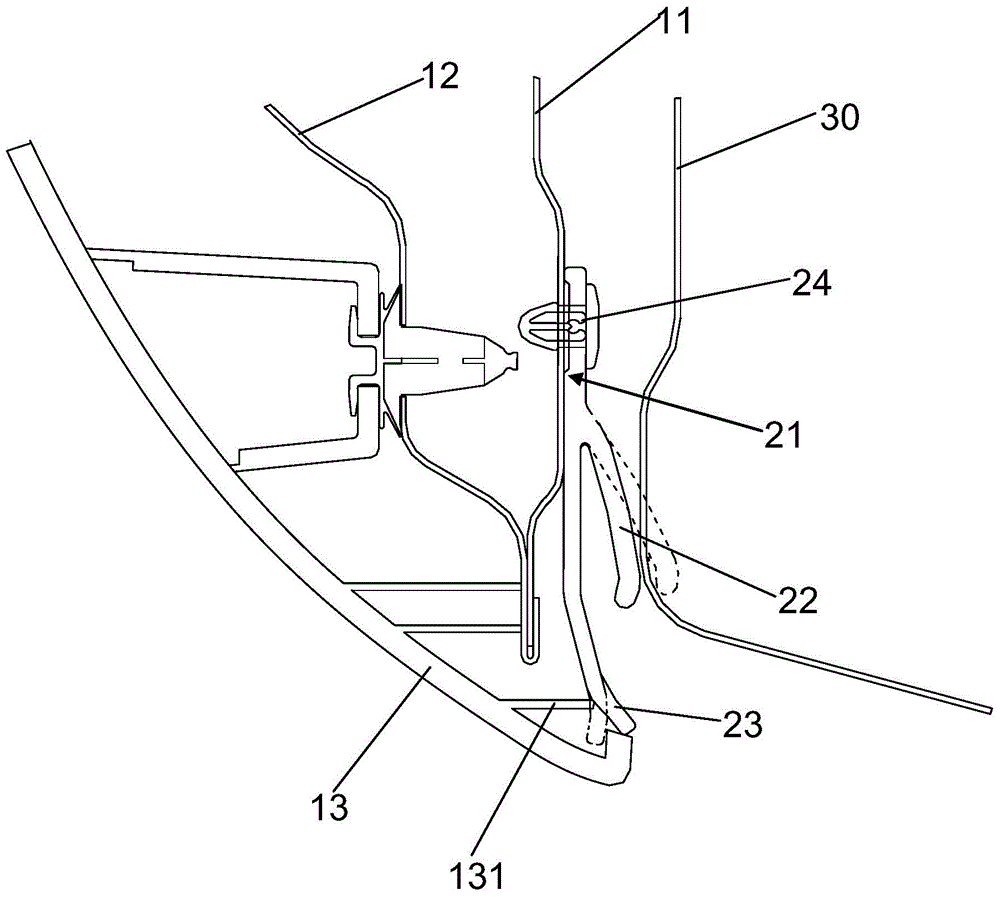

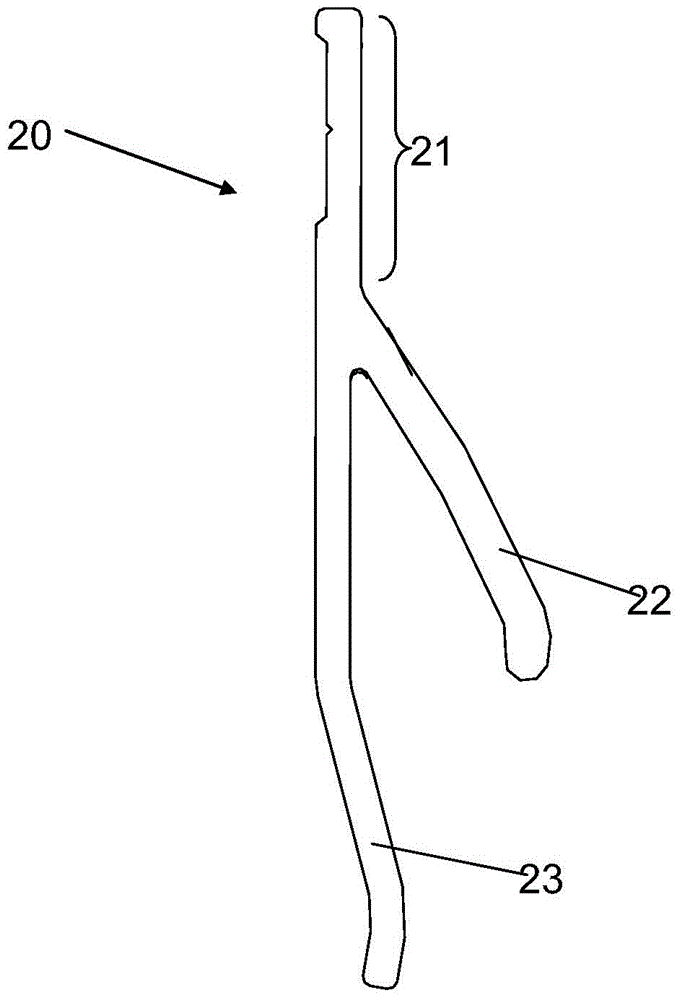

[0008] like figure 1 As shown, a door lower sealing structure, the door inner panel 11 is installed with a sealing strip 20, the sealing strip 20 includes a straight wall-shaped base 21 and a first and second lip fixed under the base 21 and in a cantilever shape. 22, 23, the first lip 22 corresponds to the position of the side wall outer panel 30 at the door sill, and when the door is closed, the first lip 22 abuts against the side wall outer panel 30, and the second lip 23 abuts against On the door trim 13 , the lower end of the door trim 13 extends below the second lip 23 , and the base 21 is provided with a through hole for connecting the door inner panel 11 .

[0009] The car door includes a door inner panel 11 and a door outer panel 12, the outer door panel 12 is provided with a door trim 13, the lower end of the door trim 13 extends downwards to the bottom of the door, that is, the door trim 13 is located at the second lip 23 below. The second lip 23 seals the joint be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com