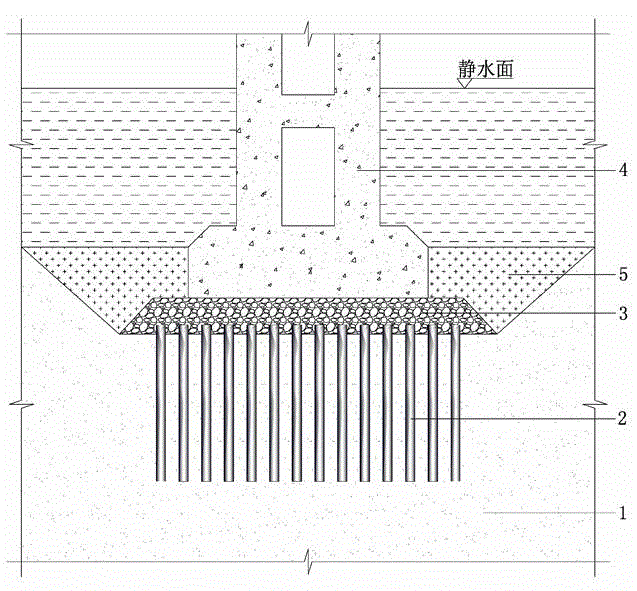

Testing device and testing method of pile composite foundation combined with broken stone hardcore foundation

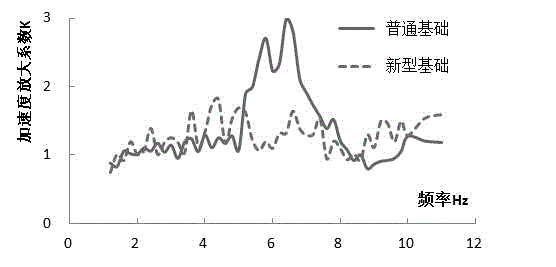

A technology of composite foundation and gravel cushion is applied in the field of structural shock absorption and earthquake resistance, which can solve the problems of waste of resources, increase of cost, and reduction of horizontal seismic shear force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

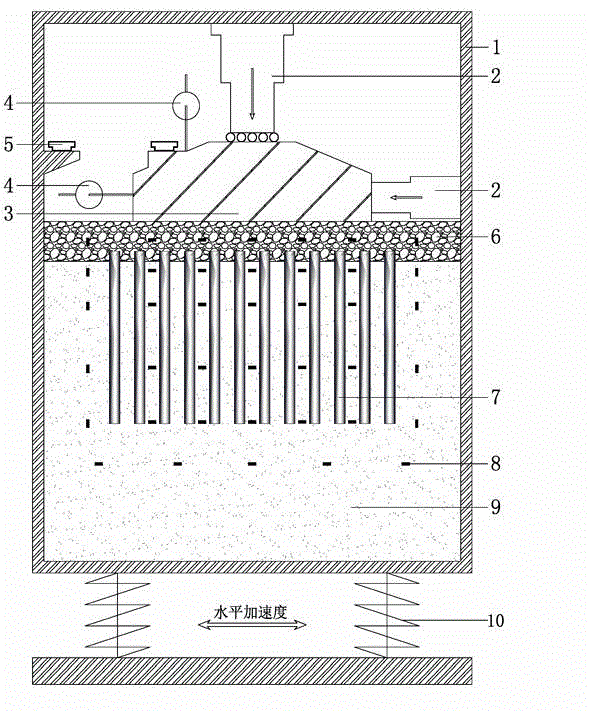

[0031] like figure 2 As shown, this embodiment adopts a seismic station full-model dynamic test device in the foundation form of a pile composite foundation and a gravel cushion. The device includes a model box 1, a reaction frame 1, a loading device 2, a rigid cap model 3, a displacement sensor 4, an acceleration sensor 5, a gravel cushion model 6, a pile composite foundation model 7, a strain gauge 7, and an earth pressure sensor 8. Sand 9, seismic station 10, etc. Model box 1 is an upper open box, and sand 9 is filled in the box, and model piles 7 are driven into sand 9 to form a pile composite foundation, and the top of the model pile is higher than the top of the sand After the pile composite foundation is formed, a cushion layer 6 simulated by sand is laid on it, and a rigid cap 3 is arranged on the cushion layer 6, and a loading device 2 is arranged on the cap, and there is a sliding device between the cap and the loading device. , the earth pressure sensor 8 is set i...

Embodiment 2

[0041] like Figure 4 As shown, the present embodiment adopts PIV camera semi-model static test device. The main difference with Embodiment 1 is: the basic model only takes half of the full model test model, and a facade of the model test container is made of transparent plexiglass, and a camera 11 for PIV shooting is installed outside the plexiglass, and the test does not need a seismic table and acceleration Displacement gauge.

[0042] The PIV video camera semi-model static test specifically includes the following steps:

[0043] (1) Put the sand 9 into the model box 1 in layers. In order to ensure the homogeneity of the soil, the thickness of each layer is controlled within 2 times the pile diameter. After compaction, continue to lay the sand 9, and lay the sand to the predetermined depth , it is necessary to place an earth pressure gauge 8 at the position shown in the figure. After the sand is laid, insert the model pile 7 with a strain gauge on the inside into the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com