System and Method for Injector Fault Remediation

A technology for injectors and faults, which is applied in the direction of machines/engines, electronic control of exhaust treatment devices, and diagnostic devices for exhaust treatment devices, etc. and mechanical hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention relates to power management systems for machines, and more particularly to power management systems and methods for preventing and, if necessary, remediating DEF injector clogging due to urea crystallization.

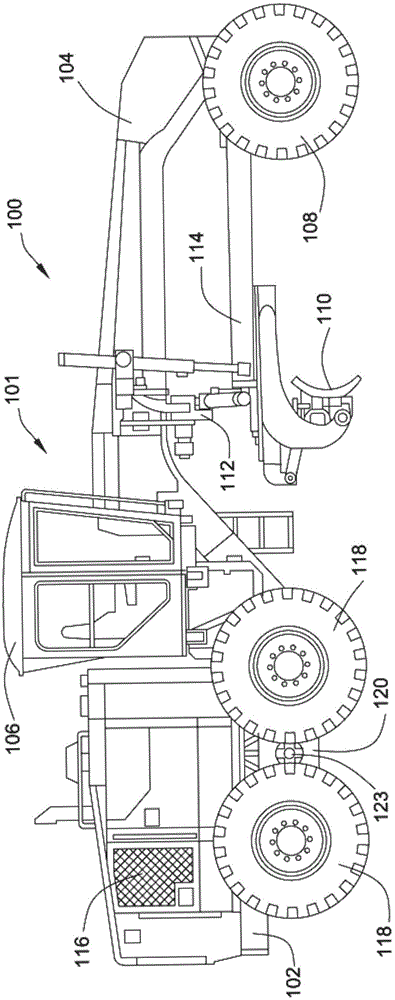

[0015] figure 1 A side view of a machine 100, which in this example is a motor grader 101, is shown in . The term "machine" is generally used to describe any machine having at least one drive wheel driven directly by a motor connected to the drive wheel, for example electrically or hydrostatically, or alternatively by mechanical means via an engine via a transmission . although figure 1 A self-propelled motor grader is shown in , but any machine performing some type of operation related to an industry such as mining, construction, farming, transportation, marine or any other industry known in the art is contemplated. For example, machine 100 may be an earth moving machine such as a wheel loader, excavator, dump truck, backhoe loader, mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com