Double-acting nut-locking hydrocylinder

A nut locking and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve problems such as the difficulty of sealing the hydraulic chamber in the jacking oil chamber, and the inability to realize the hydraulic return stroke, etc., and achieve the effect of a simple and feasible solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

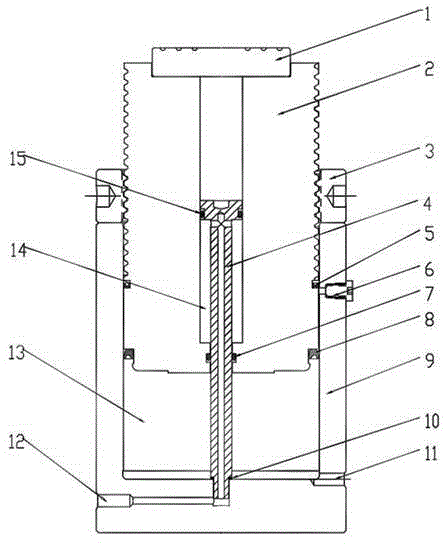

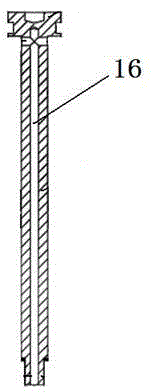

[0021] A double-acting nut-locking hydraulic cylinder as shown in the figure includes: a saddle 1, a threaded plug 2, a locking nut 3, a cylinder 9, and a return mechanism; the return mechanism includes: set on the thread The return oil cavity 14 inside the plunger 2 and the return plunger 4 reciprocating in the return oil cavity 14; in order to strengthen the sealing performance, it is also provided with: dust ring 5, return plunger piston rod sealing ring 7, threaded plunger Piston sealing ring 8, return plunger static sealing ring 10, return plunger piston sealing ring 15.

[0022] The relationship between the above components is as follows:

[0023] The saddle 1 is fixed on the top of the threaded plunger 2; the lower end of the threaded plunger 2 is inserted into the jacking oil chamber 13 of the cylinder 9, and the return plunger piston sealing ring 15 is located between the return plunger 4 and the return plunger 4. Between the contact surfaces of the oil cavity 14; the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com