Anti-loose set screw

A technology for preventing falling off and screws, applied in the direction of screws, nuts, bolts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below according to the accompanying drawings and specific embodiments.

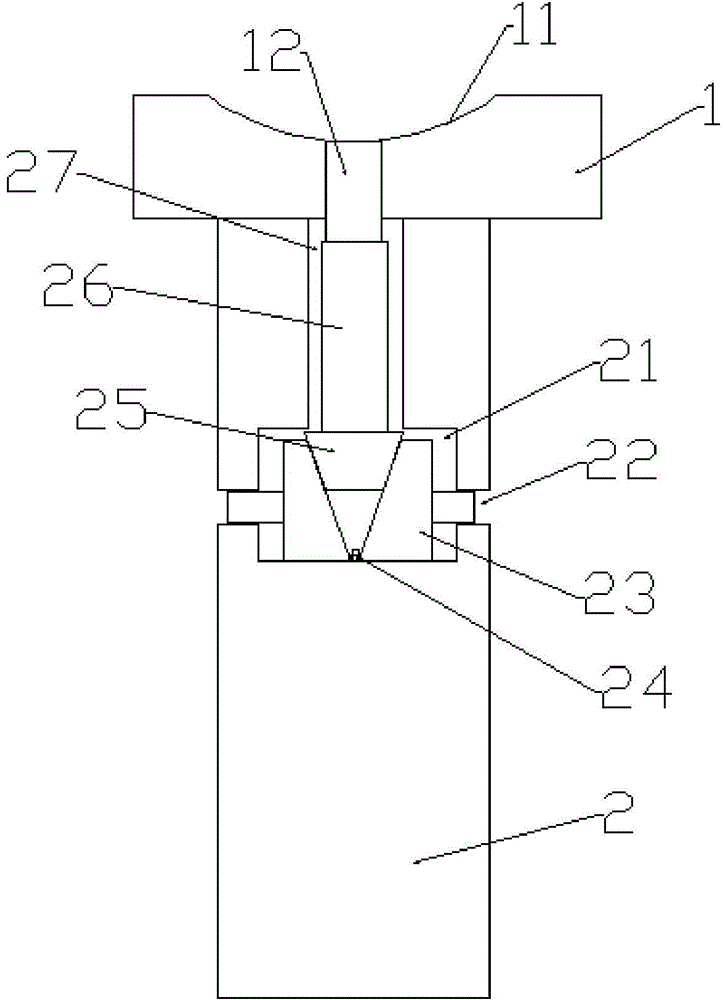

[0020] Such as figure 1 As shown, the present invention includes a nut 1 and a screw body 2, and the screw body 2 is integrally formed with the nut 1 at the top.

[0021] A cylindrical receiving groove 21 is arranged inside the upper position of the screw main body 2, and a plurality of small holes 22 are arranged on the side wall of the cylindrical receiving groove 21 along its circumferential direction, and the small holes 22 are arranged along the cylindrical receiving groove. A certain diameter of 21 is symmetrical, and each small hole 22 corresponds to a locking member 23, the head of the locking member 23 is adapted to the inner shape of the small hole 22, and can slide back and forth in the small hole 22 , the tail is slightly larger than the head, and the tail end planes of all the clamping parts 23 are on the side of an inverted truncated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com