A precision detection platform for small parts

A technology for testing platforms and parts, which is applied in the direction of measuring devices and instruments, etc., can solve the problems of affecting the production efficiency of enterprises, troublesome operation of level calibration, and difficult operation, so as to achieve efficient and fast level calibration, avoid manual adjustment operation, and detect high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

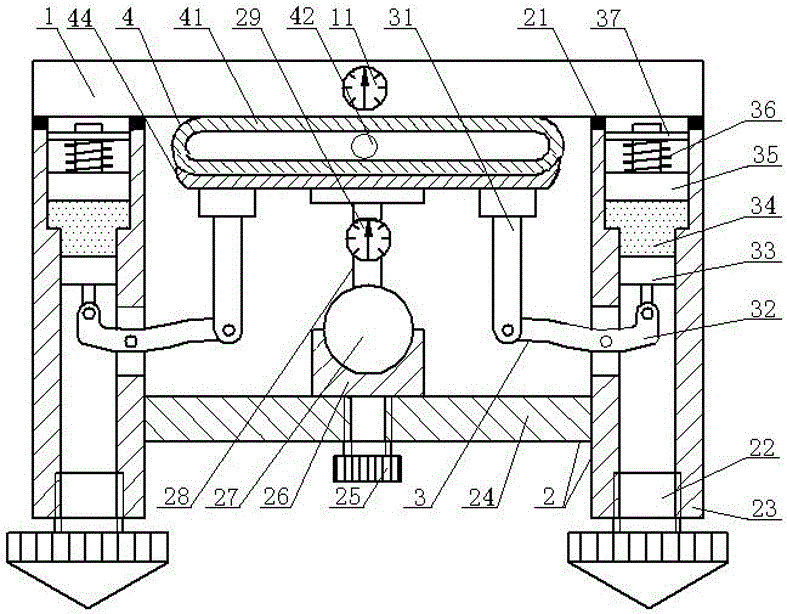

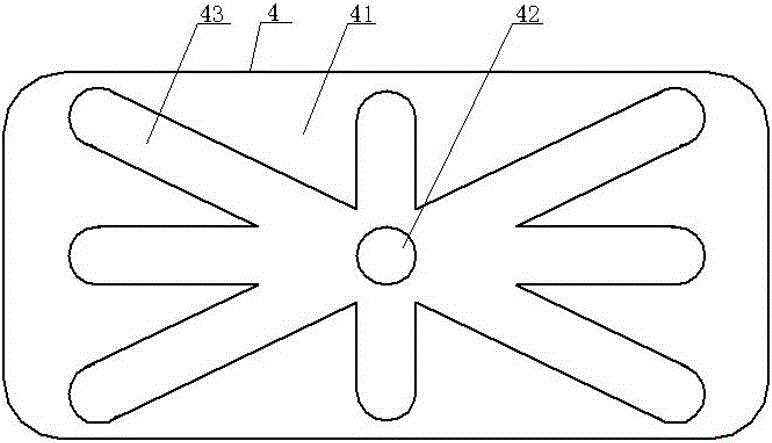

[0029] see figure 1 and figure 2 : The present invention includes a reference platen 1, a frame body 2, an inclination amplification mechanism 4 and a leveling mechanism 3.

[0030] Wherein, the reference platen 1 is used as an operation platen for testing the processing accuracy of parts, and it has a rectangular structure, the top surface and the bottom surface are flat and smooth, and the two are parallel. The four corners of the reference table 1 are support points. In order to ensure the reliability of the automatic horizontal calibration and reset, each support point is required to be at the same position from the edge of the reference table 1, that is, the four support points are centered on the center point of the reference table 1 , evenly distributed on the four corners of the reference platen 1. An inclination angle sensor is arranged on the aforementioned reference platen 1, that is, a platen inclination sensor 11, through which the sensor detects whether the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com