Method for obtaining coplane-type thin film transistor contact resistance

A thin film transistor and contact resistance technology, applied in electrical digital data processing, instruments, calculations, etc., to achieve the effect of reasonable theory, accurate results and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

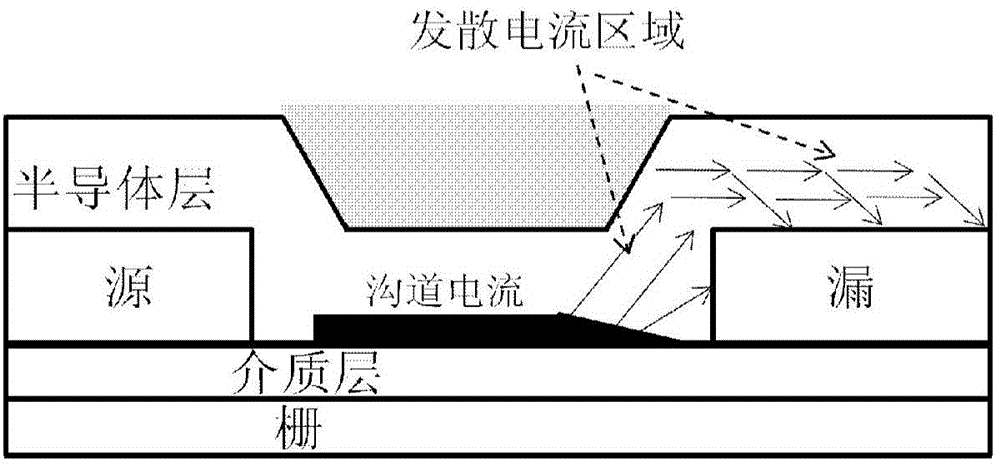

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following takes the contact resistance between the drain electrode and the channel region as an example with reference to the drawings (the contact resistance at the source electrode is the same), and the present invention is further detailed Description.

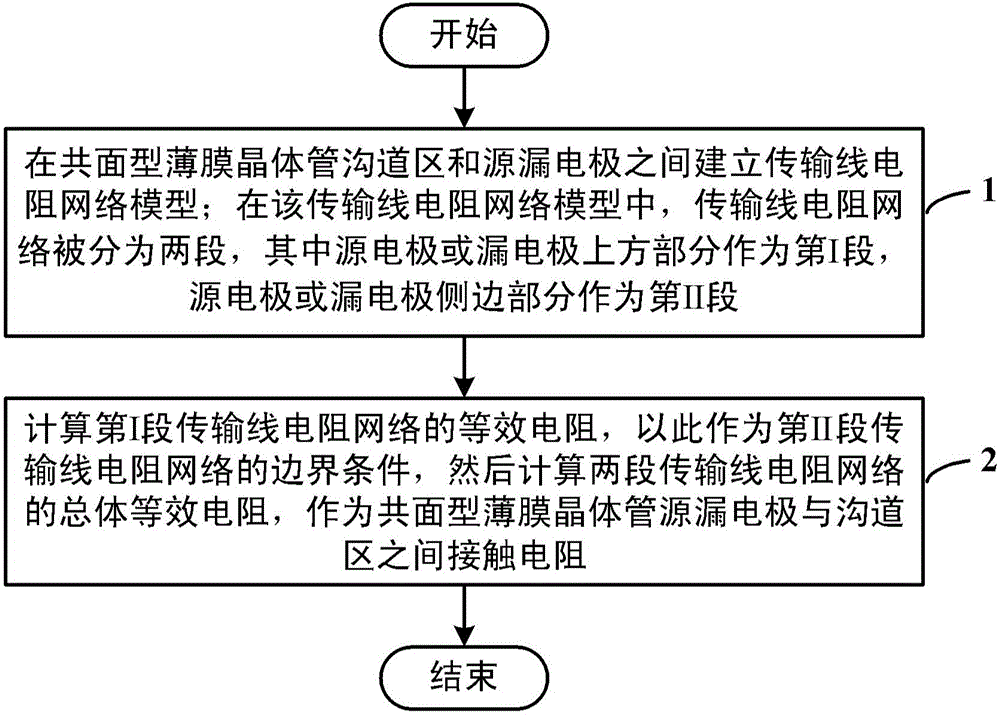

[0022] Such as figure 1 As shown, the method for obtaining the contact resistance of a coplanar thin film transistor provided by an embodiment of the present invention includes the following steps:

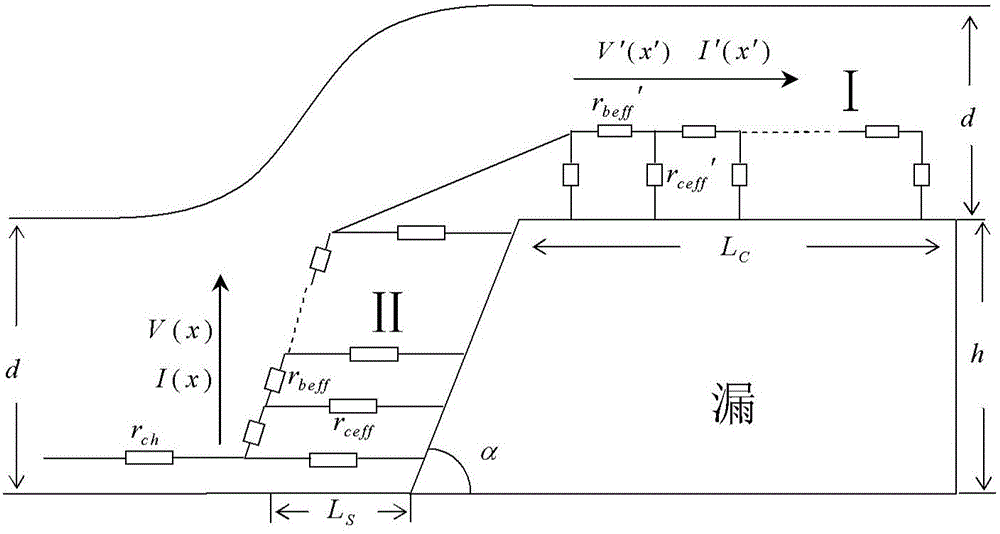

[0023] Step 1: Establish a transmission line resistance network model between the channel region of the coplanar thin film transistor and the source and drain electrodes; in this transmission line resistance network model, the transmission line resistance network is divided into two sections, where the part above the source electrode or the drain electrode serves as In paragraph I, the side part of the source electrode or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com