Method for designing optimal damping characteristics of shock absorber of vehicle steel plate spring suspension system

A leaf spring and suspension system technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber-spring combination, etc., can solve the problem of optimal damping matching of vehicle suspension, high test and design costs, and inability Satisfy issues such as vehicle ride comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

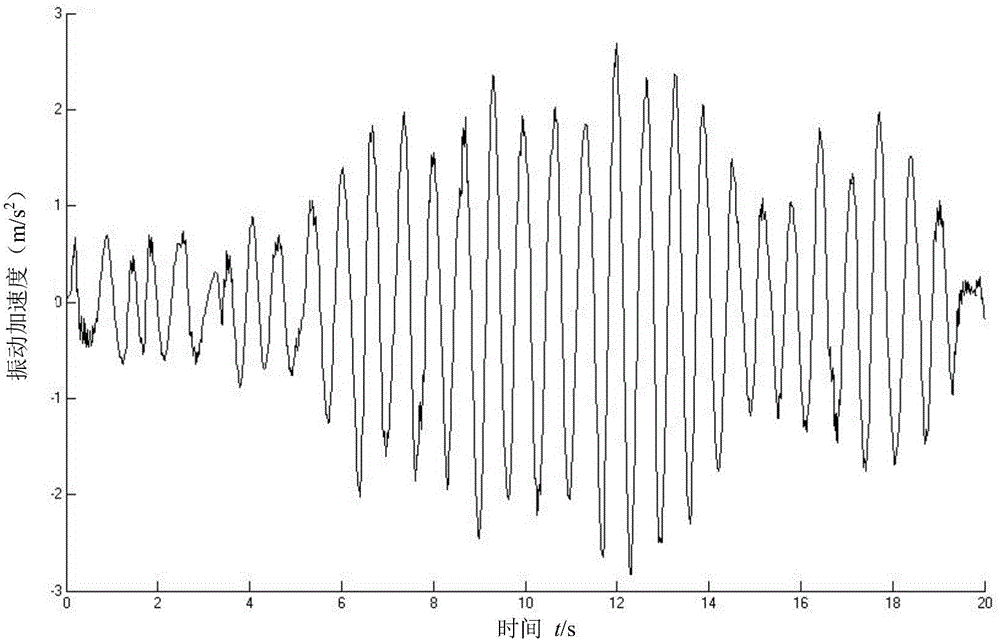

[0044] Embodiment: A certain truck adopts a leaf spring suspension system, and the sprung mass m of the front axle single-wheel suspension 2 =35000kg, unsprung mass m 1=3500kg, suspension k 2 =3618700N / m, tire stiffness k t =32568300N / m, the maximum vibration velocity of the suspension leaf spring under normal working conditions V=0.5084m / s, the installation angle of the shock absorber α=10°, and the lever ratio i=0.9.

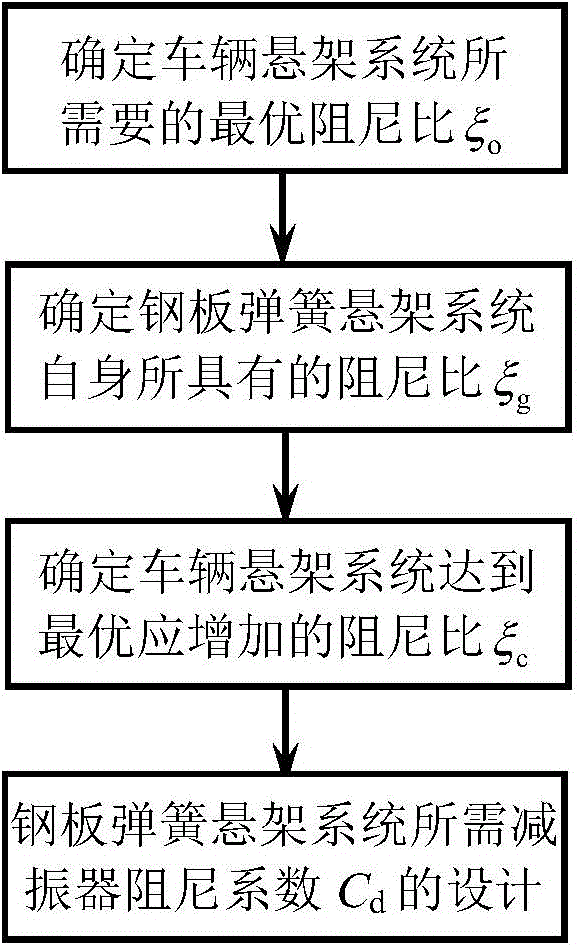

[0045] The design method of the optimal damping characteristic of the vehicle leaf spring suspension system shock absorber provided by the example of the present invention, its concrete steps are as follows:

[0046] (1) Determine the optimal damping ratio ξ required by the vehicle suspension system o :

[0047] According to the vehicle parameters, determine the optimal damping ratio ξ required by the vehicle leaf spring suspension system o ,Specific steps are as follows:

[0048] Step A: Determine the optimal damping ratio ξ of the vehicle suspension sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com