Workpiece recognition method based on geometric shape feature and device thereof

A technology of geometric shapes and recognition methods, applied in character and pattern recognition, computer parts, instruments, etc., can solve problems such as difficult to meet the requirements of actual industrial application scenarios, limited application fields, and no mention of obtaining the contour of the workpiece area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

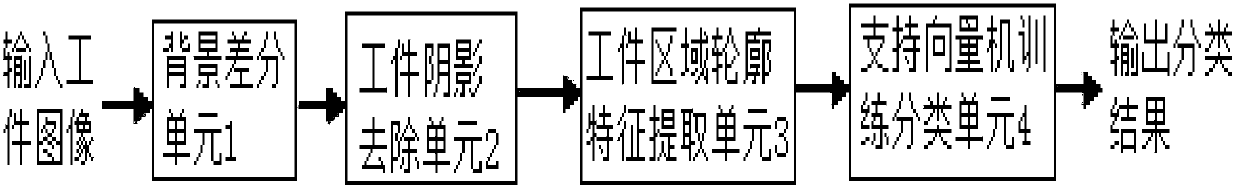

[0076] Such as figure 1 As shown, the device of the present invention includes a workpiece image background difference unit 1 , a workpiece shadow removal unit 2 , a workpiece area outline feature extraction unit 3 and a support vector machine training and classification unit 4 .

[0077] Wherein, the input end of the workpiece image background difference unit 1 inputs the two-dimensional image of the workpiece on the conveyor belt taken by the industrial camera, and the image difference operation is performed through the workpiece image background difference unit 1 to obtain the foreground area including the workpiece and its shadow, and Delivered to the workpiece shadow removal unit 2; the workpiece shadow removal of the foreground area including the workpiece and its shadow obtained by the workpiece shadow removal unit 2, to obtain the accurate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com