Forced oil circulation finned radiator of oil-immersed transformer

An oil-immersed transformer and strong oil circulation technology, applied in the field of transformers, can solve the problems of reduced life of winding insulation materials, reduced service life of transformers, slow flow of transformer oil, etc., to achieve reduced copper consumption, smaller oil tanks, and delayed aging speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

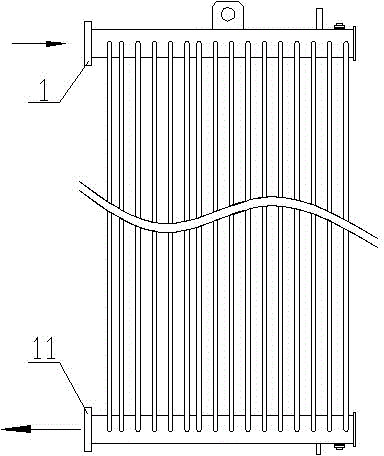

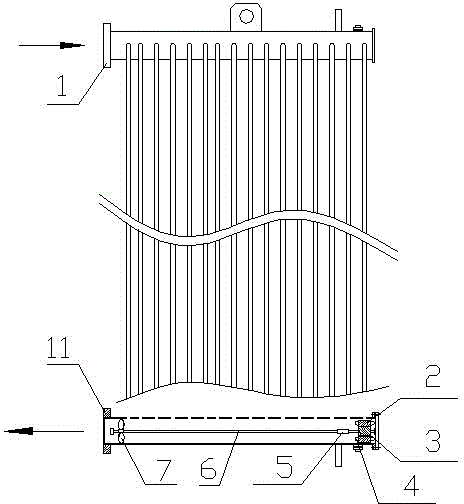

[0015] Such as figure 2 As shown, the oil-immersed transformer strong oil circulation plate radiator of the present invention includes an oil inlet flange 1 and an oil outlet flange 11 arranged on the oil-immersed transformer oil circulation pipeline, and also includes an axial flow pump, a shaft The flow pump consists of a motor, a coupling 5, a shaft 6 and an impeller 7; the motor is installed at the opposite end of the oil outlet flange 11, the motor is connected to the shaft 6 through the coupling 5, and the impeller 7 is assembled near the outlet flange 11. On the shaft 6 of the oil port flange 11.

[0016] Further, the motor includes a motor stator 2 , a motor rotor 3 and a motor winding 4 , and the motor rotor 3 drives a shaft 6 .

[0017] Preferably, the number of impellers 7 is three or more, and the number is one. Multiple numbers and multi-blade impellers 7 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com