Processing integrated device for flour product bulking particles

A technology of puffed granules and integrated devices, which is applied in the field of processing devices, can solve the problems of uneven hygienic standards of puffed granules, difficulty in meeting market demand, and high labor intensity, and achieve the effects of high degree of automation, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention are now described in detail in conjunction with the accompanying drawings, but the embodiments are only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

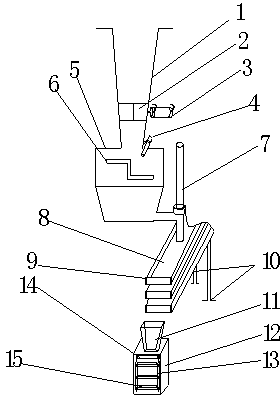

[0016] Such as figure 1 Shown is the noodle product puffed granule forming integrated device provided by the present invention, including: puffing device, conveying device, particle cutting device, and each device is composed of various small mechanisms to form a whole. The puffing device is composed of a feed hopper 1, a feed valve 2, an air pump 3, a photoelectric sensor 4, a stirring box 5, a stirring rod 6, an puffing machine 7, and a driving motor; 9. Roller bracket 10, drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com