Transverse filtering mask

A face mask, horizontal technology, applied in the field of sanitary products, can solve the problem of inhumane design and achieve the effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

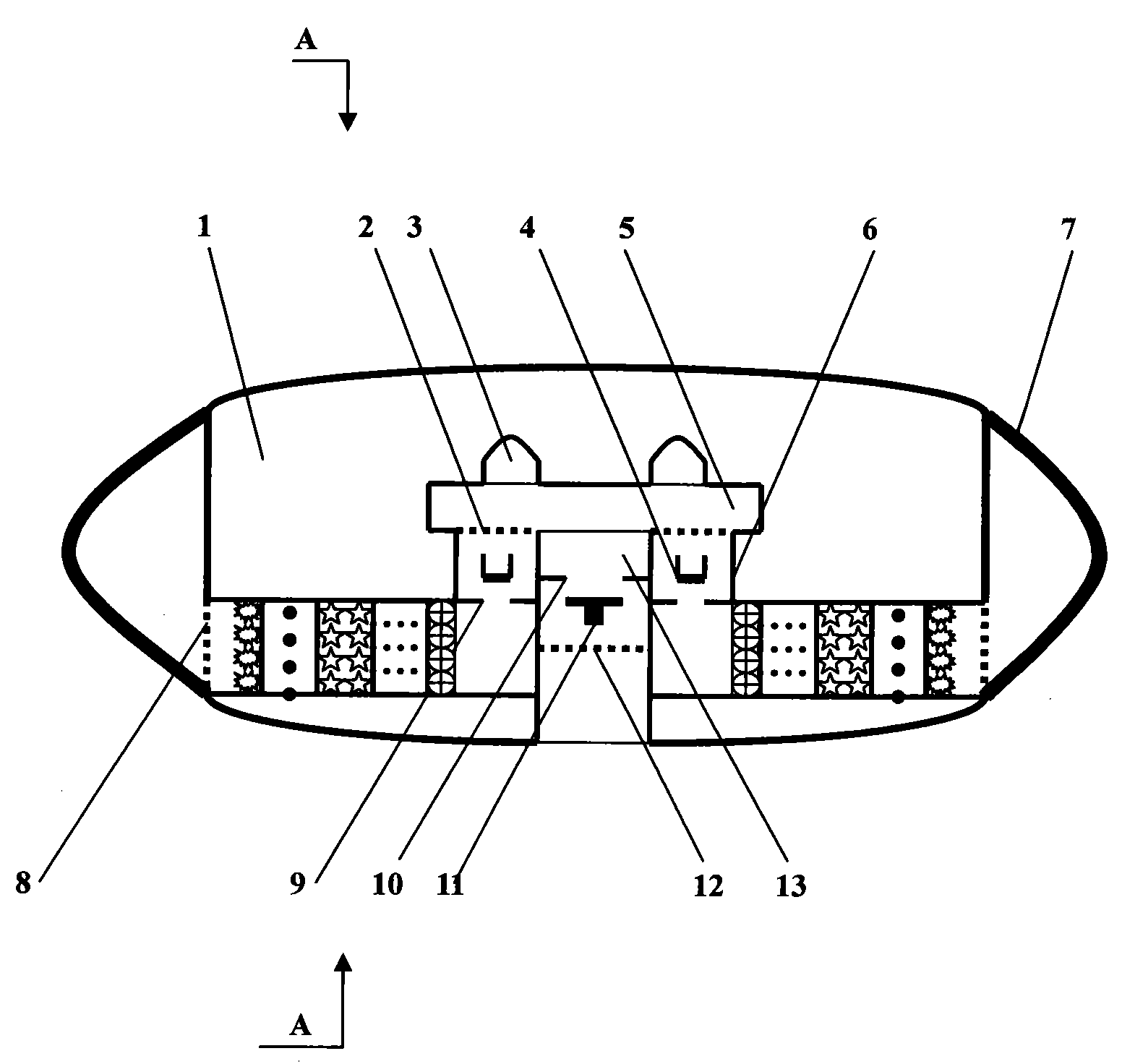

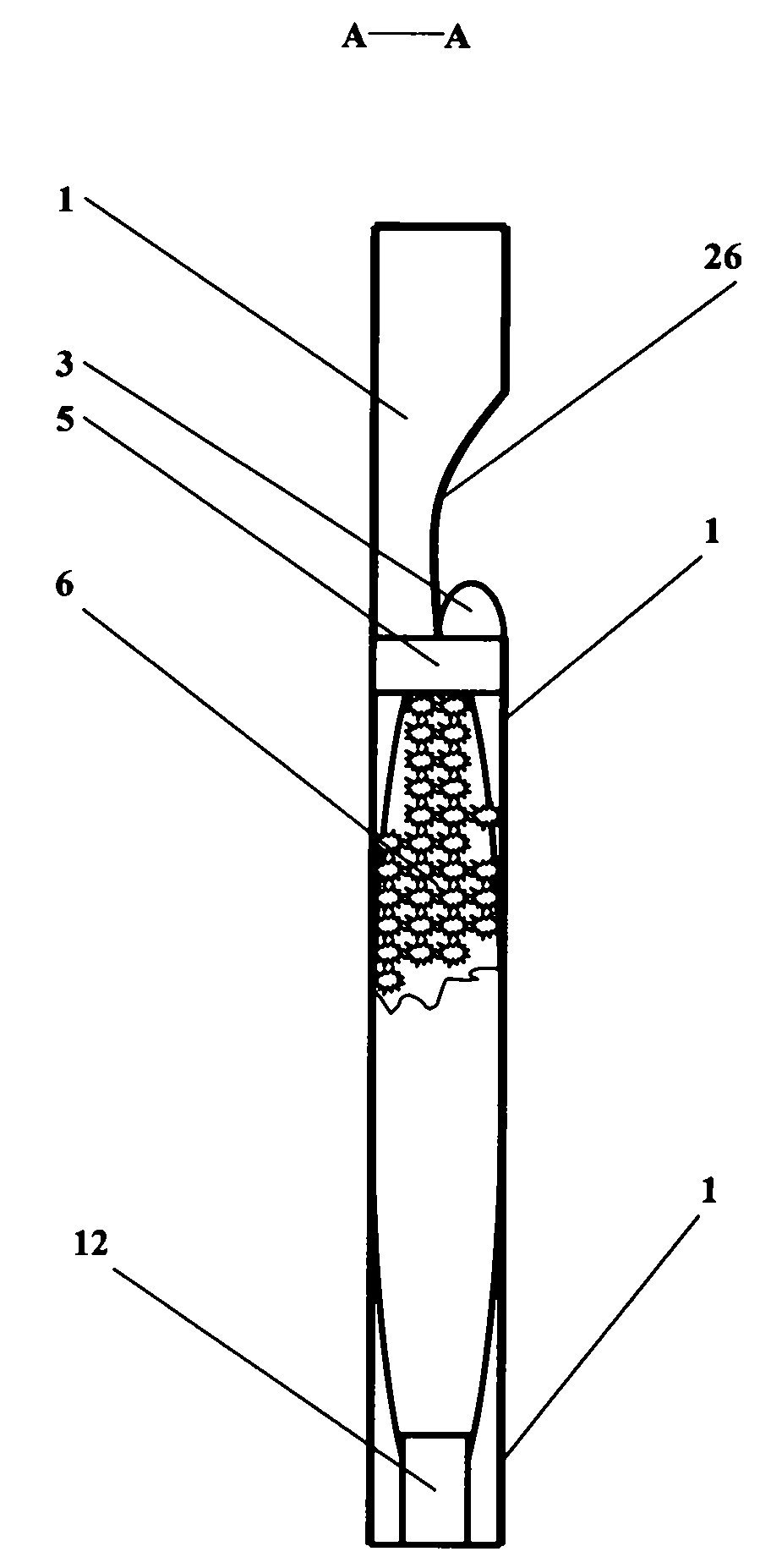

[0029] like figure 1 , figure 2 , Figure 4 As shown, the upper end of the core cavity (24) is provided with a nasal plug seat (23), the hollow nasal plug (3) is installed on the nasal plug seat (23), and the hollow nasal plug (3) is stretched out from the mask opening (26). A common chamber (5) is provided below the seat (23), an air suction chamber (6) is provided on the left side of the core chamber (24), and an air suction chamber (6) is provided on the right side of the core chamber (24), An inhalation valve (9) is housed in the inhalation chamber (6), an inhalation valve plate (4) is installed in the inhalation valve (9), and an exhalation chamber (13) is arranged in the middle of the core chamber (24). An exhalation valve (10) is housed in the air cavity (13), and an exhalation valve plate (11) is installed on the exhalation valve (10).

Embodiment 2

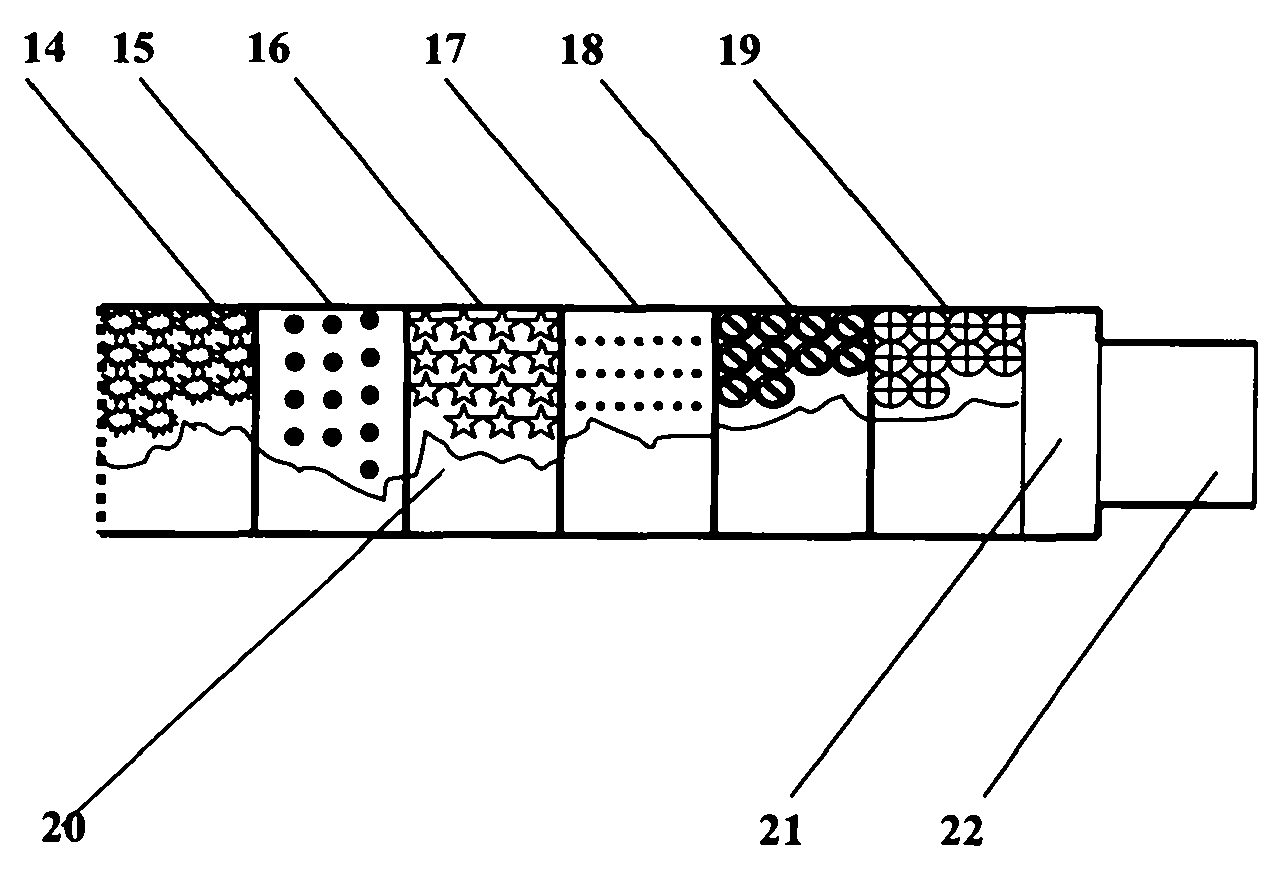

[0031] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 4 As shown, the gas purification core (20) is combined with the connection socket (25) of the suction cavity (6) through the connection plug (22), and the sterilization material (14) and the adsorption material are placed in the gas purification core (20). (15), filter material (16), harmful gas removal material (17), cleaning material (18), fragrance material (19). The connected core cavity (24) and the gas purification core (20) are jointly installed in the mask (1).

Embodiment 3

[0033] On the basis of embodiment one and example two, as figure 1 , figure 2 , image 3 , Figure 4As shown, one end of the gas purification core (20) is provided with an air intake screen (8), the other end is provided with a clean air outlet (21), and an air suction port (2) is provided in the air suction chamber (6). The lower end of the air cavity (13) is provided with an exhaust port (12). The two ends of the mouth mask (1) are provided with hanging straps (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com